Disclaimer......I'm still planning and haven't proven this out yet!! So take this "TECH" as a theory to be proven in the coming months.

I'm building at set of steering axles (both passenger drop F&R steer) following what Dan did. Stock Ford 3.25" big web centers and Dana 50 tubes and outers. I plan to try and use both tubes by removing them from the Dana 50 center. Long I feel like will work....the short may be too short for what I have planned.

The difference is that I'm building mine to use Stock of the shelf Chevy Length (17.67" short & 35.07" long) axle shafts. I ran a Chevy 60 for years and have 3 brand new sets of inner axles (two 4340 sets of inners and one CTM 300M Set of inners all machined already for 50*) so I'm going to use them.

Using off the shelf shafts all with raised seal area's and splines set up for a dana 60 creates an issue since the 9" has splines inside that differ that aren't centered left to right. For me that means that one side will have the raised seal area on the shaft inside the 3rd member.

So I started hunting for 35 spline spools that are splined all the way through. For my build I wanted a number of things. 1)Cheap. doesn't get cheaper than a off the shelf spool. 2) light. doesn't get lighter than a spool. 3) K.I.S.S. I want a simple easy to drive and maintain buggy. Again Spool is as simple and as strong as it gets.

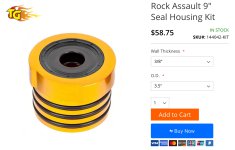

What I found so far is this from Quick Performance. Part number

F9DR35X

Per the web site this spool moved the splines to the ends of the spool which for me allows me to place the seals in the ends of the tubes in the housing. My plan is to just have tubes extend into the housing so that I can put a standard Dana 60 seal in the end of the tube and have it fall on the raised seal area that my shafts all have. I work at a machine shop so machining the seal area's into the tubes isn't an issue for me. By Allowing the tubes to stick into the factory center farther than factory I'm hoping to put a brace on the end of the tube like a lot of the aftermarket housings do.

Based on the length of the seal area on my shafts I'm going to try and put two stock Dana 60 seals in the end of each tube because why not.

As of now what I think I know is that this spool would require a "conversion bearing" IF used in a 3.25" case (nodular case). I emailed Quick Performance a couple of times asking if they had a spool with the splines at the ends for 3.25" cases but got no response. I haven't decided yet what 3rd member I'm going to run. I have plenty of 3.06" cases that I can use. I'd prefer Nodular for Strength or Aluminum for weight but Budget may mean that I use what I have which works perfectly with this Spool.

Building this way does mean I don't control the WMS of my axle. Since the spool length, the inner axles shafts length and the outers are all set the WMS is going to be what its going to be. I'm ok with that!! I haven't done exact math but the 9" spool, I THINK is going to be narrower than a Dana 60 center. Then there may be a difference between the king pin outers and the 99-04. Stock Chevy front was 67" so I think I'll be between 63"-69" WMS front and rear which is fine with me. I'd even be ok if by some miracle it ends up at 72". WMS is not really a concern for me at this point. I will build around it.

Building around this spool also means that if I EVER want to switch to a locker of any kind I'll need new inner axle shafts. This is a concern as I've wheeled with ARB's for a long time. So spools will take some getting used to. I'm hoping Rear Steer and taking advantage of FWD or RWD options will help with that.

I'm still a couple of weeks away from ordering parts and starting on the housings to prove this theory out. I'm building these for my current build but i'm not in ANY rush! I'm building them for fun because I LOVED the Housing that Dan built! So while it's budget thats not my goal. I just wanted a cool project to work on.

If anyone knows for SURE of another 9" spool that moves the splines to the ends instead of the factory placement Please let me know! I may also look at using inner seals like Landy_Andy posted for a couple of reasons i'll explain later IF i do that.