[486]

ugh, that guy again?

thisDo you just need a filter base?

looks like you could switch it out for a generic filter base to use a much more generic primary fuel filter from like a cat 3206 or somesuch

thisDo you just need a filter base?

I'm on this right now. Sifting through Summit.this

looks like you could switch it out for a generic filter base to use a much more generic primary fuel filter from like a cat 3206 or somesuch

Looking through results now. I'll have one picked out and ordered before bed.Ok, unfortunately I suffer from c.m.s., but I have the solution for you, I can get you part numbers tomorrow or search for "perma cool filter base"

This is the filter that I use with it.Ordered one. Have to assume the seal face fits. Perma-Cool doesn't show that info.

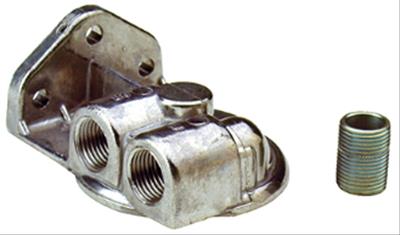

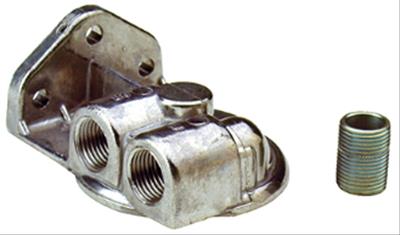

Perma-Cool 1724 Perma-Cool Remote Oil Filter Brackets | Summit Racing

Free Shipping - Perma-Cool Remote Oil Filter Brackets with qualifying orders of $109. Shop Oil Filter Mounts at Summit Racing.www.summitracing.com

I'd really like a water separator though. Already have the separator filter and a spare. Surely it'll fit.

Right, I just posted that so you can compare dimensions of the two.I'd really like a water separator though. Already have the separator filter and a spare. Surely it'll fit.

Dang. The filter o-ring on mine is just barely gonna fit.

grab the o-ring off an old filterForgot to get crank case cleaner or seafoam this morning. Krud Kutter concentrate did the trick. Followed that up with vinegar and water boil. Coolant and fuel passages are now flowing freely.

For gaskets, the cap just needs an o-ring. The exchanger uses a tall, square-cut, just like an oil or fuel filter. I'm going to see if I can still browse through filter o-ring dimensions in catalogs.

Don't have that convenience at the moment. Will be purchasing whatever cheap filter has the correct o-ring.grab the o-ring off an old filter

The battery box is as low as the steps and fuel tank. I can raise it up 2 or 3 inches because there's a third set of bolt holes to mount it as it designed to be mounted.Is the battery box the lowest point now? Could you raise it some without messing stuff up?

The reason for that is in your title. Being a former salt truck causes issues like this.This truck does some weird stuff

No kidding. I have family with boats on the ocean and the salt damage is fun.The reason for that is in your title. Being a former salt truck causes issues like this.

They're surprisingly fairly solid, considering the use and abuse. There's plenty of rust and expansion in some places, but lots of good steel left.Being a salt truck and all, how are the frame rails? Mine are jacked really bad and I'm going to cut it up. I plan to make new rail sections to splice in, shorten the truck and set a crane on it. Eventually lol.

These are jacked so far the outer is bent like 45° on the flange. See if you can knock that stuff out by hitting the flanges. It gets bad fast.They're surprisingly fairly solid, considering the use and abuse. There's plenty of rust and expansion in some places, but lots of good steel left.

I've been eyeing this every time I lift the bed. Thinking maybe a wood blade in the sawzall to knock the flakes out.These are jacked so far the outer is bent like 45° on the flange. See if you can knock that stuff out by hitting the flanges. It gets bad fast.

Sledge, a shop vac, and some pick tool.I've been eyeing this every time I lift the bed. Thinking maybe a wood blade in the sawzall to knock the flakes out.

If you knock a bunch of "structural oxidation" out, hose the freshly exposed areas down with phosphoric acid (like Ospho).I've been eyeing this every time I lift the bed. Thinking maybe a wood blade in the sawzall to knock the flakes out.

What year, model and engine is yours?Sledge, a shop vac, and some pick tool.

It went from I should take care of that to totally shot in 2 years.

Right on.It's a twin axle 4900. I forget the year (late 90s- early 00s) but engine is a dt466e.

I don't know if it's been brought up already, but have you ever had it over 55 other than downhill? 55 and 60 were fairly common governed speeds for that era plow truck, especially with a wing.Right on.

I still need to figure out why my dt466e is having difficulty with the injection pressure. Get up to 55mph/1800rpm and let off the pedal a bit, it defaults to idle until I coast down to 50mph/1600rpm.