TTMotorsports

Red Skull Member

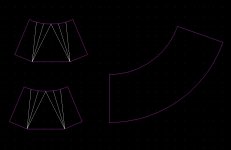

Took the lower/upper link mounts off the frame and got those all welded up and trimmed to fit. Welded transmission crossmember mount up on frame since edge of link mount hits that and hides the joint to weld. Also got the lower backhalf tube in since I removed it for new link mounts and longer lower links/cutting the frame off more.