I'm FINALLY getting decent prints on the CR-10V2 again, down right amazing prints compared to what I was getting. There's room for improvement but the upgrades, "down grades," and new parts have me back in business.

Biggest improvement, I ditched the Micro Swiss nozzle and went back to a factory replacement Creality nozzle, set my G code extrusion back to stock too of course.

Probably the next best upgrade are beefier die springs on the bed level adjustment screws. I don't know if I got a lemon, but the original springs never held much tension with the bed trammed. I made shims out of some rubber gasket material to increase tension, but I ditched the stock springs and DIY shims for some skookum springs. Very happy with how solid the bed is now and I'm not having to retram it every five minutes.

I added the CR Touch probe and requisite firmware like mentioned before. I'm not going to admit how many times I crashed it setting my Z offset after installing the sensor, Creality's Chinglish instructions were a challenge. Thankfully some nice folks way smarter than me made some YouTube videos to follow. I added a G29 code in my machine parameters so it probes the bed before every print now too.

I put a new magnet pad and textured, flexible, bed on since my old one was kind of beat up. After my Z offset saga though, my old flexible plate is in better shape than the new one.

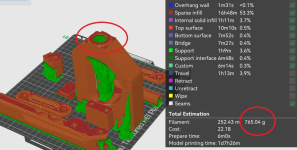

I printed a PETG Benchy right away and was mostly happy with it, made some slicer adjustments and made a real part.

This is to hold a hose and data cable in a panel mount gland nut. Gland nut needs to be big enough for the sensor to get through and the sensor's cable is preterminated with a non-servicable big barrel connection, hence clam shell design. I made it snap together like Legos.

I giggled a little when the two halves snapped together. Very satisfying!

Thanks everyone for all the help with this stupid thing!