ditcherman

Member

- Joined

- Jun 20, 2024

- Member Number

- 7907

- Messages

- 8

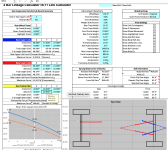

Thanks, not the first time I’ve made that mistake on the centers distance. I should have known.I can probably answer some of this.

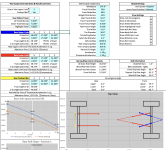

His rear uppers are 5 inches apart. The 2.5 is distance from the center line.

3 link setups are slightly easier to package the uppers than a triangulated setup since you are beside the engine. He has some advantage in that his lowers are below the axle tube.

I’m doing the same thing on my front three link as far as dropping the axle end below the CL.