YellowTurtle

Member

- Joined

- Mar 28, 2024

- Member Number

- 7673

- Messages

- 20

As an update:Yep, both at same time. I didn't drive it before switching ends because... delayed gratification.

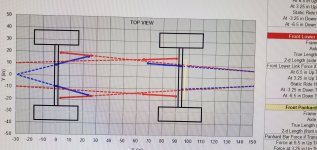

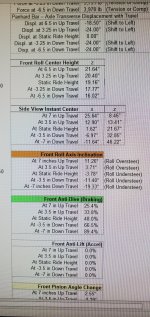

All arms 25-26" (so 1 spare works), 3 link front, double triangulated rear, tried to keep lower arms flat and tucked up for clearance+good numbers. The only unusual aspect is the narrow ends of rear triangles have some horizontal separation because of packaging, but have more than enough triangulation between upper+lower. Only other change was rear spring mount moved.

TJ with about 3-3.5" lift over stock. Outboarded shock in rear end extended shock tower in front, but already had that with short arms.

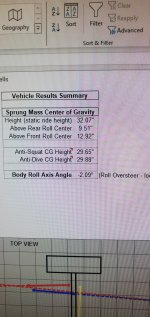

Recap: on my TJ I'm running rear double triangulated and front 3 link. Has around 3-4deg roll understeer in front and a couple deg roll understeer in back. Overall, chassis had roll oversteer per calc. Been fighting wobbly/oscillating/roll oversteer feeling since out the links on.

I straightened out the rear lowers so now they have about 13deg of angle total (previously had about 40deg) and the uppers stayed the same at 35ish deg total. Calc says this changed the roll understeer in the rear to 1-2deg of rear roll oversteer, and also made the total chassis have more oversteer. It drives much much better than before. Maybe not 100% perfect but a significant difference and much more relaxing to drive.