Provience

Kill!

alright, procrastination continues and now i've got questions.

Slowly gathering stuff to swap away from my C6 behind my 400.

irate4x4.com

irate4x4.com

the above thread talks about making the swap behind a 7.3 IDI.

72Pstroke says:

granted, i'll need about twice the RPM that the IDI is shifting at, but it leads me to my thoughts from earlier in the day.

Can I use a PCM for a 1990 460 w/E4OD, which is ~$1-200, and run it with the transmission harness hooked up and just tag the engine with a TPS signal and tachometer signal? 1978 F250 with edelbrock carb would be easy enough to adapt to a TPS.

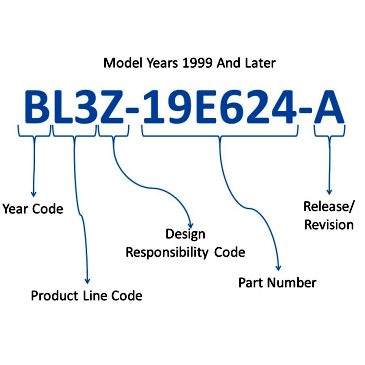

OE No. F0TF-ATA and/or OE No. E9TF-RA according to Rock Auto

the other option is the great tunability options from US Shift or MSD or others, those are ~$700-1,000 for wiring, plug and play.

rattle_snake 1972 F-250 2wd to 4wd build is running the US SHIFT quick 6 for his 6r80

edit: addding a link here EEC-IV basics EEC-IV tech info thread, all over

Slowly gathering stuff to swap away from my C6 behind my 400.

1989 F350 7.3L C6 swap to OD Trans

OK so i'm going to look at a good deal 1989 F350 with a 7.3L with a C6 trans with 160K Miles. The front axle is also a monobeam style 2WD could I swap out the trans to a E40D or newer 4R100 with 4x4 and swap in a 8 lug solid front axle to convert to 4x4 and get a US Shift controller to handle...

the above thread talks about making the swap behind a 7.3 IDI.

72Pstroke says:

I forget what years (Early 90's?) it was available, but Ford offered the E4OD with the 7.3 IDI. They used a standalone ECU, and I think a standalone harness. I think there is a FIPL (fuel injection pump lever) sensor on the engine, and that was about it.

Or put a ZF5 in it.

granted, i'll need about twice the RPM that the IDI is shifting at, but it leads me to my thoughts from earlier in the day.

Can I use a PCM for a 1990 460 w/E4OD, which is ~$1-200, and run it with the transmission harness hooked up and just tag the engine with a TPS signal and tachometer signal? 1978 F250 with edelbrock carb would be easy enough to adapt to a TPS.

OE No. F0TF-ATA and/or OE No. E9TF-RA according to Rock Auto

the other option is the great tunability options from US Shift or MSD or others, those are ~$700-1,000 for wiring, plug and play.

rattle_snake 1972 F-250 2wd to 4wd build is running the US SHIFT quick 6 for his 6r80

edit: addding a link here EEC-IV basics EEC-IV tech info thread, all over

Last edited:

seems like it could really be a doable thing.

seems like it could really be a doable thing.

whateva.

whateva.  I REALLY want a 6r80 (well, 6r140 but US Shift doesn't make a controller for it) in the motorhome as it would dramatically help with towing due to the first gear reduction and the different split between 3/4

I REALLY want a 6r80 (well, 6r140 but US Shift doesn't make a controller for it) in the motorhome as it would dramatically help with towing due to the first gear reduction and the different split between 3/4