AgitatedPancake

Frobot

They are not really sized great for the sheer size of a WJ radiator, and I can get my DD hot on demand unfortunately. I do believe part of the issue is the size of the transmission cooler I run, but I want to have my cake and eat it tooi just did the volvo relay (thanks bebop) with taurus fan and i am not sure how it could improve. i mean that trip out my fan ran in low everybit of 75% of the time. now if it could act like a dimmer switch that would be cool. and maybe that what it can do.

I took this video a while back for my fan controller testing, but it shows the max fan speed pretty well

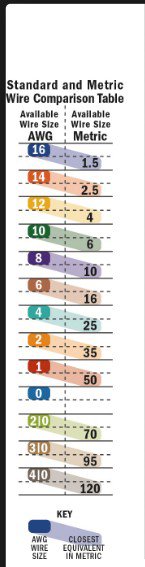

were deal in freedom units in

were deal in freedom units in