You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hummer H3 Build

- Thread starter 06h3

- Start date

Ok, I’ve been back from the hammers a little over a week now and it’s time to address more things to improve on. It’s so funny to reminisce on how just doing a SAS was just such a big jump in performance gains I couldn’t imagine there was anything to improve on.

I know the SAS of 2014 can’t even remotely touch the SAS today in really any aspect but I keep pushing for a better performing rig.

So now it’s steering….steering angle to be specific. The steering has really been up to the task for many years and pretty much left untouched. I’d throw a new 1.5in .25 wall mild steel tie rod in every year or two because I’d bend em. Replace a TRE or heim every once in a while but the power to turn tires has never been an issue, especially since ram assist.

Steering angle though sucks, it’s always sucked. 43s made it worse. Well, I can’t blame 43s, I can blame that my 43s are extremely wide. I always hit the lower control arms at full lock on a 40x13.5 but now it’s worse.

With all that said, you would think it’s time to just change control arm location and move on but I’m trying to take a ground up approach.

What must stay is my steering box (Nissan xterra) and pitman arm. Everything else is game.

I can’t cycle a full 8in ram. My pitman arm is currently 4 7/8 or 5in long (off of memory) Can’t make it even a 1/2in longer. It will hit the track bar bracket.

Steering arm on the pass side is like 7in and change. Way too long for that pitman arm. I can move it to the tie rod hole (my tie rod is in the factory low steer position) that is 5in long.

I was thinking of buying this.

www.skysoffroaddesign.com

www.skysoffroaddesign.com

Run it in the tie rod hole at 4.25 from kingpin center line. That “should” gain me a ton of steering angle. My goal is to hit the factory steering stops which I can’t do right now even if I had 2in wide tires with 1in of backspacing. The box doesn’t have that much throw.

So, I’d hope I can hit the stops with that steering arm. I’d need to make a new drag link to miss the track bar bracket on the axle side, that’s ok.

Then I need to figure out my control arms. I can bend them like ruffstuff has “pre bent” control arms

www.ruffstuffspecialties.com

www.ruffstuffspecialties.com

I worry I will fuck those up since I can fuck up straight arms as is it is.

So I can go with slightly less backspacing of 3.25? I’m 3.5 currently. Which I’m sure the 3.5in backspacing doesn’t help scrub radius and steering angle as it is but that’s an easy way to gain some room. I’d also consider moving my links inboard on the frame and get more angle on them. I’m hoping though I could cheat the existing brackets with custom misalignment spacers to offset the heim in the bracket. Gain me a tad more room and .25in less backspacing and get enough to turn more.

Anyways, anyone have any input? I don’t have a ton of experience with steering arms, pitman arms, Ackerman angles, scrub radius, and just steering angle in general.

I know the SAS of 2014 can’t even remotely touch the SAS today in really any aspect but I keep pushing for a better performing rig.

So now it’s steering….steering angle to be specific. The steering has really been up to the task for many years and pretty much left untouched. I’d throw a new 1.5in .25 wall mild steel tie rod in every year or two because I’d bend em. Replace a TRE or heim every once in a while but the power to turn tires has never been an issue, especially since ram assist.

Steering angle though sucks, it’s always sucked. 43s made it worse. Well, I can’t blame 43s, I can blame that my 43s are extremely wide. I always hit the lower control arms at full lock on a 40x13.5 but now it’s worse.

With all that said, you would think it’s time to just change control arm location and move on but I’m trying to take a ground up approach.

What must stay is my steering box (Nissan xterra) and pitman arm. Everything else is game.

I can’t cycle a full 8in ram. My pitman arm is currently 4 7/8 or 5in long (off of memory) Can’t make it even a 1/2in longer. It will hit the track bar bracket.

Steering arm on the pass side is like 7in and change. Way too long for that pitman arm. I can move it to the tie rod hole (my tie rod is in the factory low steer position) that is 5in long.

I was thinking of buying this.

Dana 60 High Steer Steering Arms

Sky's has been building Dana 60 King Pin high steer ( Hi Steer) arms since 2001! We have been continually developing better arms as the years go by. We have now come up with what we think is the best Dana 60 Steering arms available. Most options, most features, best materials!The extra thickness...

www.skysoffroaddesign.com

www.skysoffroaddesign.com

Run it in the tie rod hole at 4.25 from kingpin center line. That “should” gain me a ton of steering angle. My goal is to hit the factory steering stops which I can’t do right now even if I had 2in wide tires with 1in of backspacing. The box doesn’t have that much throw.

So, I’d hope I can hit the stops with that steering arm. I’d need to make a new drag link to miss the track bar bracket on the axle side, that’s ok.

Then I need to figure out my control arms. I can bend them like ruffstuff has “pre bent” control arms

High Clearance Lower Link, DOM Tube, 2" X .25" Wall, 1.5" Tube ID

Check out the deal on High Clearance Lower Link, DOM Tube, 2" X .25" Wall, 1.5" Tube ID at RuffStuff Specialties

I worry I will fuck those up since I can fuck up straight arms as is it is.

So I can go with slightly less backspacing of 3.25? I’m 3.5 currently. Which I’m sure the 3.5in backspacing doesn’t help scrub radius and steering angle as it is but that’s an easy way to gain some room. I’d also consider moving my links inboard on the frame and get more angle on them. I’m hoping though I could cheat the existing brackets with custom misalignment spacers to offset the heim in the bracket. Gain me a tad more room and .25in less backspacing and get enough to turn more.

Anyways, anyone have any input? I don’t have a ton of experience with steering arms, pitman arms, Ackerman angles, scrub radius, and just steering angle in general.

RunningProblem

Well-known member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,456

If you take the tires off can you hit the steering stops?

If you can’t hit the steering stops, what do you think will happen when a hydraulic ram is pushing or pulling the pitman arm farther than the box will allow?

If you can’t hit the steering stops, what do you think will happen when a hydraulic ram is pushing or pulling the pitman arm farther than the box will allow?

Taking the tires off I still can’t hit the steering stops.If you take the tires off can you hit the steering stops?

If you can’t hit the steering stops, what do you think will happen when a hydraulic ram is pushing or pulling the pitman arm farther than the box will allow?

Full crank on each end of the box I’m not fully utilizing the 8in travel ram.

I guess I need to find a way to get more throw and I think less distance from kingpin centerline to drag link center line will do that right?

RunningProblem

Well-known member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,456

yes on the more throw. My brain says if your steering box is at it’s max, and you now as a hydraulic ram to keep pushing you are going to break something when you LEAST want it to break. Maybe it’s a tie rod on the pitman arm instead of the drag link, or if everything goes heims maybe you’re tearing the Nissan box off the frame.

Edit: this is just my thinking. I’m not experienced and I’m definitely no professional.

Edit: this is just my thinking. I’m not experienced and I’m definitely no professional.

I know it’s against the “rule” as the rule of thumb is have a ram that is the limiter, not the box. I’ve had a ram that has more travel then the box for years without issue. Honestly, it was probably the tires hitting the control arms before the ram maxed out the box.yes on the more throw. My brain says if your steering box is at it’s max, and you now as a hydraulic ram to keep pushing you are going to break something when you LEAST want it to break. Maybe it’s a tie rod on the pitman arm instead of the drag link, or if everything goes heims maybe you’re tearing the Nissan box off the frame.

Edit: this is just my thinking. I’m not experienced and I’m definitely no professional.

As for more throw, I can achieve that with or longer pitman arm OR a shorter steering arm from kingpin/balljoint centerline to drag link connection point correct?

RunningProblem

Well-known member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,456

Yeah connecting the ram closer to the kingpin gives you more steering angle with the same amount of throw. You’re probably right about the tires being a bigger limit if they’re already contacting the control arms.

chaplinfj60

Well-known member

if i understand correct, you make alot of three point turns because you cant get max out of steering? and you have two limiting factors, pit man arm and tires hitting.

tires would be easy to solve with a spacer just to test out and see if you hit control arms, and if not then rims. the pit man arm is hard to address for sure. its interesting drama for sure

i cant offer much besides if its just more turns on a trail take comfort knowing your not maxing out you axle joints.

tires would be easy to solve with a spacer just to test out and see if you hit control arms, and if not then rims. the pit man arm is hard to address for sure. its interesting drama for sure

i cant offer much besides if its just more turns on a trail take comfort knowing your not maxing out you axle joints.

willis_racing

Wee Todd Did

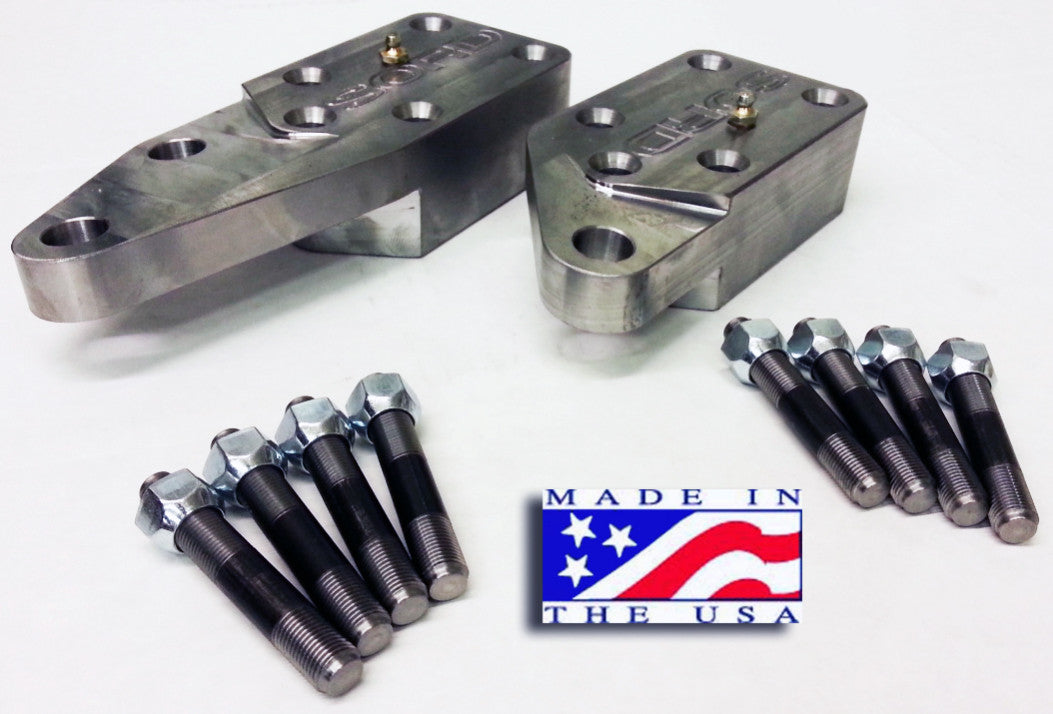

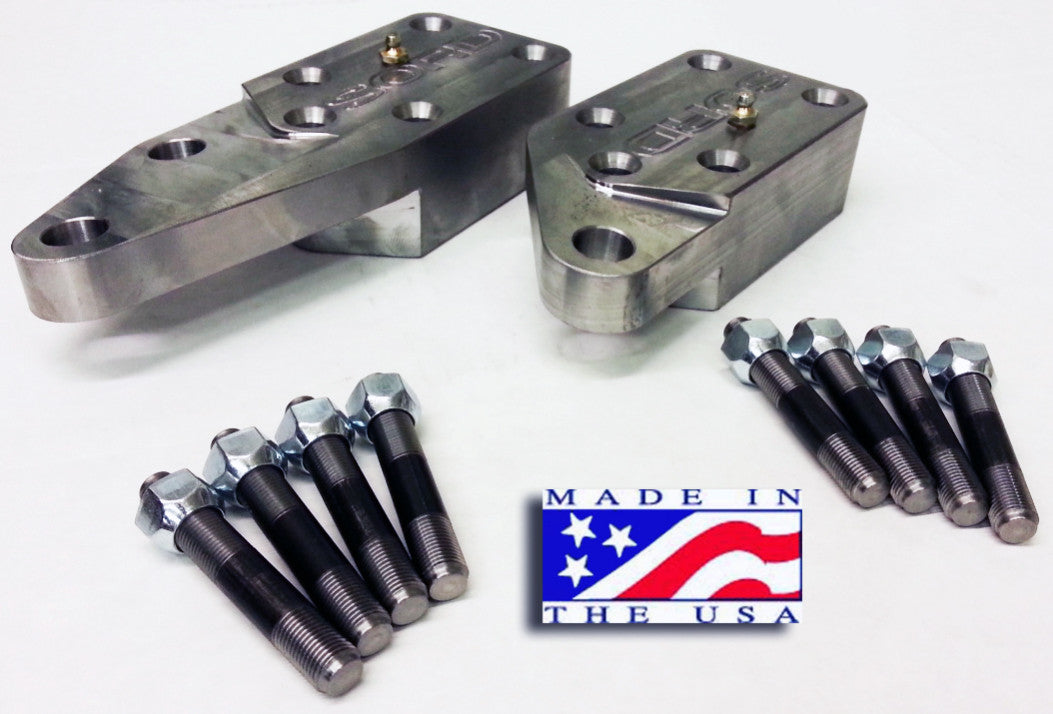

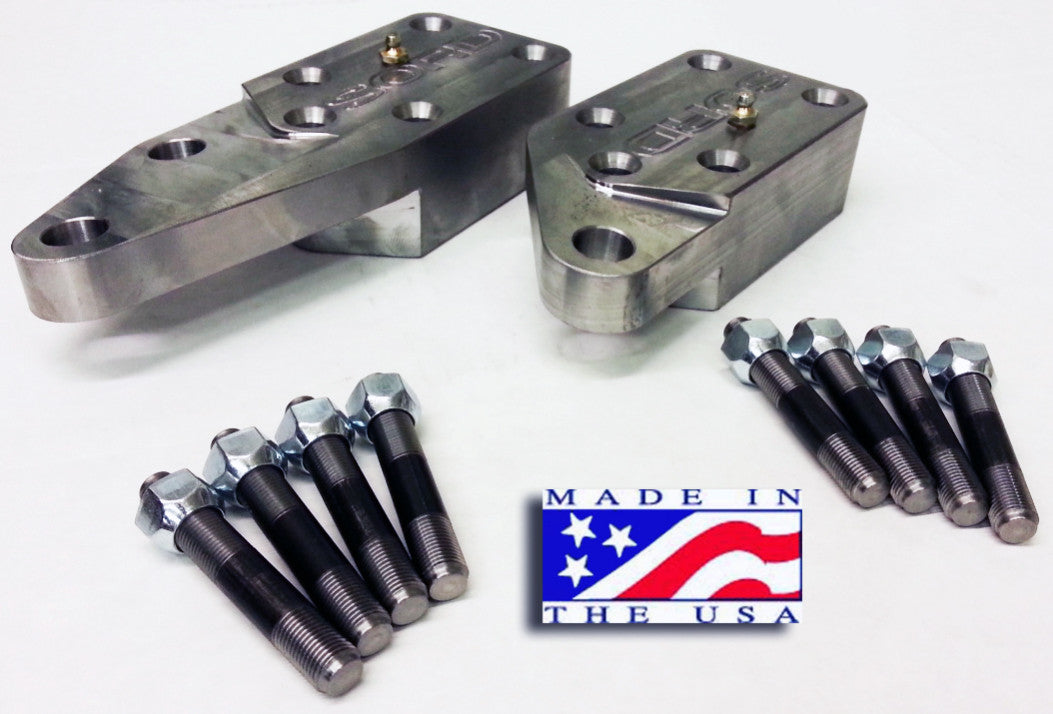

Here's an Ebay link from another Irate member for a cheaper setup than Sky's if it matters to you. I just bought this last night.I was thinking of buying this.

Dana 60 High Steer Steering Arms

Sky's has been building Dana 60 King Pin high steer ( Hi Steer) arms since 2001! We have been continually developing better arms as the years go by. We have now come up with what we think is the best Dana 60 Steering arms available. Most options, most features, best materials!The extra thickness...www.skysoffroaddesign.com

Run it in the tie rod hole at 4.25 from kingpin center line. That “should” gain me a ton of steering angle. My goal is to hit the factory steering stops which I can’t do right now even if I had 2in wide tires with 1in of backspacing. The box doesn’t have that much throw.

So, I’d hope I can hit the stops with that steering arm. I’d need to make a new drag link to miss the track bar bracket on the axle side, that’s ok.

Linky

I also had the same thought about running my drag link in the tie rod hole for more steering angle, but I'm thinking it may not actually be necessary for me. Should work in theory for you though as long as you're not looking to move the tie rod up to the high steer location.

Personally I think giving the bent control arms a whirl before messing with backspacing or spacers is worth a try. They may bend sooner but as you admit, lower control arms are already a wear item for the rig, so maybe just keep track of whether or not they get messed up faster?Then I need to figure out my control arms. I can bend them like ruffstuff has “pre bent” control arms

I worry I will fuck those up since I can fuck up straight arms as is it is.

Anyways, anyone have any input? I don’t have a ton of experience with steering arms, pitman arms, Ackerman angles, scrub radius, and just steering angle in general.

I think creating more tire clearance in the suspension itself is a better option than adding scrub radius on a heavy rig with balloon tires. Scrub radius kinda works like a long differential gear in my head, transfers more stress to all the other steering components upstream.

RunningProblem

Well-known member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,456

I must have totally misunderstood something…

On my Jeep I’m using the tie rod hole for my drag link. I couldn’t get everything to fit up high so I’m using the stock Ford location for the tie rod. I get full lock to lock steering.

I adjusted my steering stops on the knuckles to match my steering box (stock jeep). I’m only on 13.5” wide 40s.

If I can make it work I might use the driver side high steer arm as an attachment point for my hydraulic assist ram.

On my Jeep I’m using the tie rod hole for my drag link. I couldn’t get everything to fit up high so I’m using the stock Ford location for the tie rod. I get full lock to lock steering.

I adjusted my steering stops on the knuckles to match my steering box (stock jeep). I’m only on 13.5” wide 40s.

If I can make it work I might use the driver side high steer arm as an attachment point for my hydraulic assist ram.

Thanks for all the replies guys.

While the tires are limiting now I know fixing the tire issue first will only net me a small gain before the box running out of travel. I will get the super short steering arm, get as much travel out of it as possible. Then when I know I can get enough angle I’ll fix the tire issue. Thanks for the link on the steering arm. I’m curious if they sell just one arm. I only need the pass side

While the tires are limiting now I know fixing the tire issue first will only net me a small gain before the box running out of travel. I will get the super short steering arm, get as much travel out of it as possible. Then when I know I can get enough angle I’ll fix the tire issue. Thanks for the link on the steering arm. I’m curious if they sell just one arm. I only need the pass side

willis_racing

Wee Todd Did

Looks like they doThanks for all the replies guys.

While the tires are limiting now I know fixing the tire issue first will only net me a small gain before the box running out of travel. I will get the super short steering arm, get as much travel out of it as possible. Then when I know I can get enough angle I’ll fix the tire issue. Thanks for the link on the steering arm. I’m curious if they sell just one arm. I only need the pass side

Lincoln

Well-known member

- Joined

- May 20, 2020

- Member Number

- 408

- Messages

- 190

I’m slow today and also too lazy to look all the way back to get a glimpse of what you have now.

on several setups I’ve had to custom drill the arms and run heims to get around similar issues. Run the drag link on top of the arm and the tie rod under. Usually do a simple box around the heim to give the bolt support on both sides. On many it’s tough to get the drag link in the right spot and the tie rod out of the way.

on several setups I’ve had to custom drill the arms and run heims to get around similar issues. Run the drag link on top of the arm and the tie rod under. Usually do a simple box around the heim to give the bolt support on both sides. On many it’s tough to get the drag link in the right spot and the tie rod out of the way.

RSwenson

Active member

- Joined

- May 20, 2020

- Member Number

- 731

- Messages

- 29

Hey 06,,,,

I read back a few pages but didn't see anything,,,

Why no Full Hydro?

A bit spendy but is solves a bunch of problems.

Loosing the steering box and drag link was the best thing I ever did to my rig.

You don't seem to be running this on the street much.

You have plenty of weight, wheelbase and certainly tire to pull it off.

I drive from South Lake back to IceHouse Rd with no issues.

Admittedly, its 50-55 MPH due to the mountain rd, and the Subarus.

(I run 8deg caster with 42" MTRs, 114" wheelbase, 4,900lbs with 2 dudes and gear for overnight)

I'd guess you are closer to 6K and have a bit lager tire.

Seems like a no brainer??

Just my .02

Cool Rig though!

I read back a few pages but didn't see anything,,,

Why no Full Hydro?

A bit spendy but is solves a bunch of problems.

Loosing the steering box and drag link was the best thing I ever did to my rig.

You don't seem to be running this on the street much.

You have plenty of weight, wheelbase and certainly tire to pull it off.

I drive from South Lake back to IceHouse Rd with no issues.

Admittedly, its 50-55 MPH due to the mountain rd, and the Subarus.

(I run 8deg caster with 42" MTRs, 114" wheelbase, 4,900lbs with 2 dudes and gear for overnight)

I'd guess you are closer to 6K and have a bit lager tire.

Seems like a no brainer??

Just my .02

Cool Rig though!

YotaAtieToo

Thick skull

If you're buying arms, why not buy something like the artecs that tie into the stock tie rod hole, plus give you a large area to drill holes where you need. I have been able to use a clamp with a hiem to test locations before drilling.

Guessing by looking at a Pic seems like a great way to throw away $300.

Guessing by looking at a Pic seems like a great way to throw away $300.

Thanks, I agree. Full hydro solves a lot of problems. Gets rid of packaging issues, etc. My concern is how I like full hydro on the road.Hey 06,,,,

I read back a few pages but didn't see anything,,,

Why no Full Hydro?

A bit spendy but is solves a bunch of problems.

Loosing the steering box and drag link was the best thing I ever did to my rig.

You don't seem to be running this on the street much.

You have plenty of weight, wheelbase and certainly tire to pull it off.

I drive from South Lake back to IceHouse Rd with no issues.

Admittedly, its 50-55 MPH due to the mountain rd, and the Subarus.

(I run 8deg caster with 42" MTRs, 114" wheelbase, 4,900lbs with 2 dudes and gear for overnight)

I'd guess you are closer to 6K and have a bit lager tire.

Seems like a no brainer??

Just my .02

Cool Rig though!

While I don’t drive it much on the road I still put a little over 1,000 miles a year on it. Most of that is on road, as you know, an entire day of wheeling can be 5 miles total.

I have been trailering it over 300 miles one way but I drive it if it’s under 300 miles. I still hop on the freeway and in spots the speed limit is 80, but at a minimum 65-70.

How is the steering feel? I get so much conflicting info on that.

I only need one arm so it’s like $150 and I’m not guessing. The dimensions are listed on the site and I compared it to my current arms. If I can’t get full throw at 4.25in from kingpin centerline to drag link hole I’m probably SOL as you can’t get it much shorter then that.If you're buying arms, why not buy something like the artecs that tie into the stock tie rod hole, plus give you a large area to drill holes where you need. I have been able to use a clamp with a hiem to test locations before drilling.

Guessing by looking at a Pic seems like a great way to throw away $300.

YotaAtieToo

Thick skull

Before you buy, figure out the exact length you need.

This reminded me of a pm conversation I had with Sterlingfire which started out by mistake. We somehow collectively came up with a pretty simple way to calculate throw, arm length or angle.

It may get a little harder if you're shooting for less than 45* angle, but either way the math isn't that hard.

This reminded me of a pm conversation I had with Sterlingfire which started out by mistake. We somehow collectively came up with a pretty simple way to calculate throw, arm length or angle.

No worries, now Im actually curious.

This is what I came up with.

45* angle is actually 90* of swing lock to lock right?

Using a Google 90* triangle calculator

8" hypotenuse, I get 5.655" so right in your guess.

I don't think the ram cares about the arc since the a-b is the same?

Does that all makes sense to you?

Well now you don't need trial and error.

I'm not exactly sure why i didn't use this little handy dandy equation to find the sine/ tangent of the hypotenuse.

It's very easy lol

8÷1.414=5.657

Since it's an isosceles right triangle, and we know the hypotenuse is 8", we know both the sine and tangent are equal...5.657 for both legs on the right angle, being 90°.

You can check the math by doing the opposite.

5.657x1.414=~8

If you wanted to use a 10" ram, you would need a hole at very close to 7-1/16"

10÷1.414=7.06

Most people go with the stock tre position, and need a 9" stroke ram, because the stock tre position is about 6-3/8" from center of pivot... so

6.375x1.414=~9

Thanks for jogging my memory and making me feel like a dumb ass

Now my math lesson(that i needed) is over.

It may get a little harder if you're shooting for less than 45* angle, but either way the math isn't that hard.

Lincoln

Well-known member

- Joined

- May 20, 2020

- Member Number

- 408

- Messages

- 190

I’ve always done it the dumb way. If the throw of the box is 100 degrees and I want 40 degrees of steering that works out to 80%, (40+40)/100. So if center to center at the pitman arm is 5”, 5/0.8=6.25 (center of ball joint to center of drag link hole).

You can use a simple triangle calculator or YotaAtieToo math to find the degrees of the box. Same at the knuckle.

We’re saying the same thing Or pretty close. Just remember to measure once and order three times. That’s the only way to get it golden.

You can use a simple triangle calculator or YotaAtieToo math to find the degrees of the box. Same at the knuckle.

We’re saying the same thing Or pretty close. Just remember to measure once and order three times. That’s the only way to get it golden.

YotaAtieToo

Thick skull

How do you guys obtain total angle? With a laser or something?

Angle finder?

Lincoln

Well-known member

- Joined

- May 20, 2020

- Member Number

- 408

- Messages

- 190

Started this reply 3 hours ago.

Turn it to full lock. Pick a spot that is straight to measure to. Turn it full lock the other way and measure again. Take the measurements and put into this calculator.

www.calculator.net

www.calculator.net

Sides A and B will be equal and that's your pitman arm center to center.

Side C is the distance measured above. Basically the swing of the arm.

Make sure the angle degrees are blank.

With the measurements above it would have a 78.333 degree swing.

Turn it to full lock. Pick a spot that is straight to measure to. Turn it full lock the other way and measure again. Take the measurements and put into this calculator.

Triangle Calculator

This free triangle calculator computes the edges, angles, area, height, perimeter, median, as well as other values and a diagram of the resulting triangle.

Sides A and B will be equal and that's your pitman arm center to center.

Side C is the distance measured above. Basically the swing of the arm.

Make sure the angle degrees are blank.

With the measurements above it would have a 78.333 degree swing.

Lincoln

Well-known member

- Joined

- May 20, 2020

- Member Number

- 408

- Messages

- 190

Oh and I have used a protractor to do it. Not super exact but it works.

These are super handy if you don't have one. Come in a bunch of sizes.

These are super handy if you don't have one. Come in a bunch of sizes.

I have one of those laying around somewhere and of course I can’t find it.

I’m throwing 35* of steering out there. Just because I think it’s reasonable. Idk what I have now but it’s not that.

I am at 5.875 of throw side to side and the arm is 4.875. That got me to .945 so 94.5%.

4.875/.945 is 5.15so I need the hole at 5.15 not 7 3/8 where I’m at now.

40* of steering gets me at a steering arm length of 4.51

My existing steering arm one hole in can get me probably around 30-32* steering if I move it into the inside hole.

The sky’s offroad steering arm gets me to 43ish* of steering at 4.25

Doing backwards math my existing arm gets me 25ish* of steering.

I’d say since I hit my control arms I’m guessing I’m probably closer to 20* of steering which is trash.

I’m throwing 35* of steering out there. Just because I think it’s reasonable. Idk what I have now but it’s not that.

I am at 5.875 of throw side to side and the arm is 4.875. That got me to .945 so 94.5%.

4.875/.945 is 5.15so I need the hole at 5.15 not 7 3/8 where I’m at now.

40* of steering gets me at a steering arm length of 4.51

My existing steering arm one hole in can get me probably around 30-32* steering if I move it into the inside hole.

The sky’s offroad steering arm gets me to 43ish* of steering at 4.25

Doing backwards math my existing arm gets me 25ish* of steering.

I’d say since I hit my control arms I’m guessing I’m probably closer to 20* of steering which is trash.

YotaAtieToo

Thick skull

20* sounds insanely bad, but I'd bet a lot of trail rigs aren't too far off.

Sterlingfire

ignant

Man those 43's are really limiting what you can get. I'll bet moving the control arms closer together at the frame will not get you much more then you already have. Less back space on your wheels will help on paper, but it will create more problems then they will eliminate IMO. How close do your tires come to contacting your frame at full lock both ways? I remember reading somewhere that stock super duty axle get almost 38° steering. I wonder where kingpin axles are when measuring stop to stop?