arse_sidewards

Red Skull Member

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,555

So not to derail the H3 thread anymore....

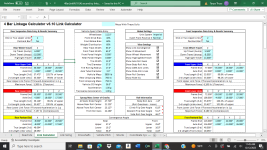

What are the desert guys who run parallel 4-links running for separation between axle centerline and track bar mount and how much angle are they running?

I know historically some of those guys have run stupid low roll centers but I'm not sure what the current state of things is.

So it sounds to me like if you need a high roll center more than you need it to feel good in the whoops that's the way to go.As you raise the axle side mount you start to make it a lever arm that pushes laterally on the track bar whenever the axle articulates. The taller that mount is the longer the lever and more push you get side to side. You will feel the body being pushed around. It is a similar feel, but different to having a lot of angle on the track bar itself. It reacts to different terrain than the track bar angle issue, but creates a similar feel.

What are the desert guys who run parallel 4-links running for separation between axle centerline and track bar mount and how much angle are they running?

I know historically some of those guys have run stupid low roll centers but I'm not sure what the current state of things is.