dnsfailure

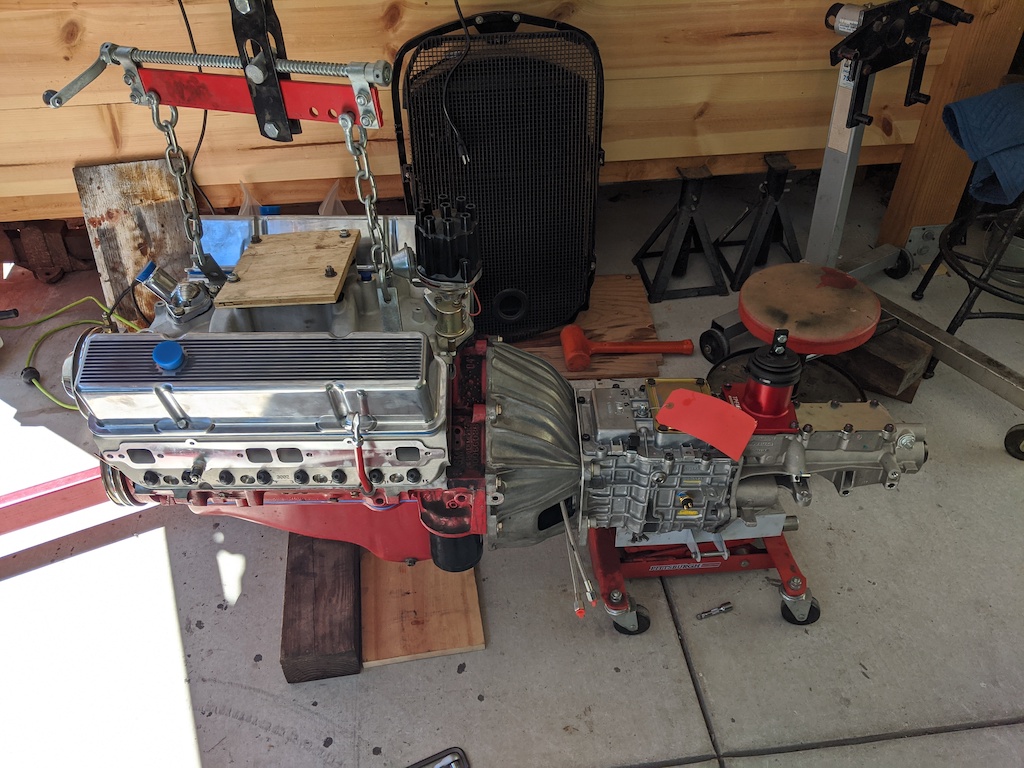

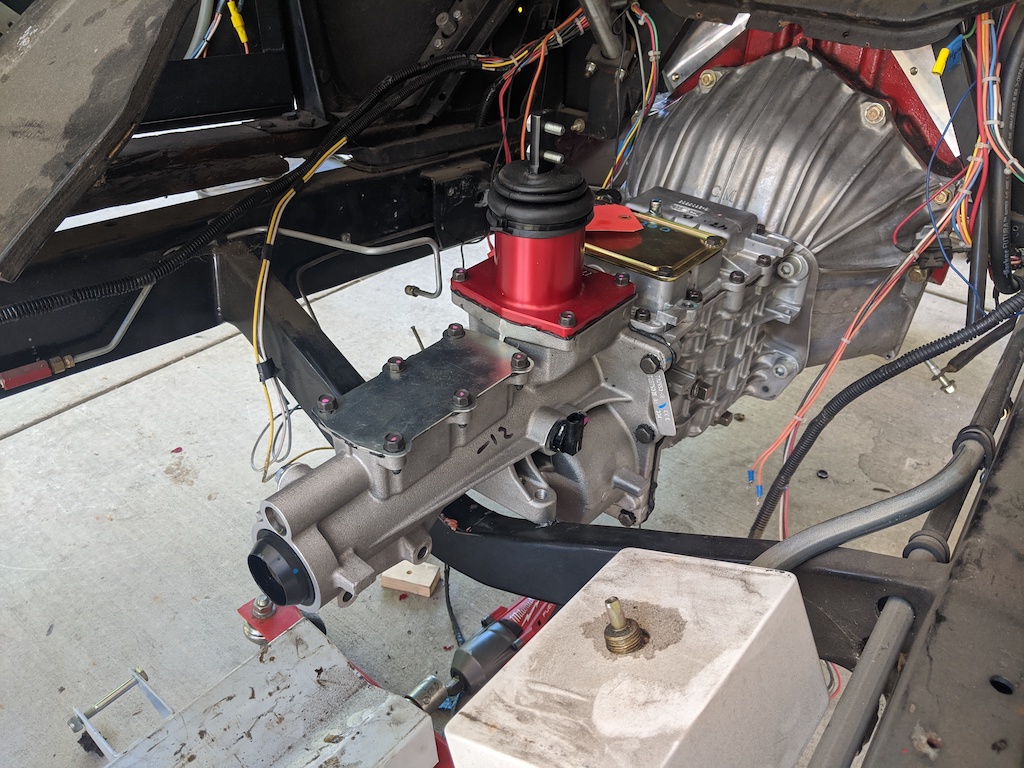

WHAT GEAR ARE YOU IN?

Just got cought up. Nice work! Is your friend going to drive the alky soon?

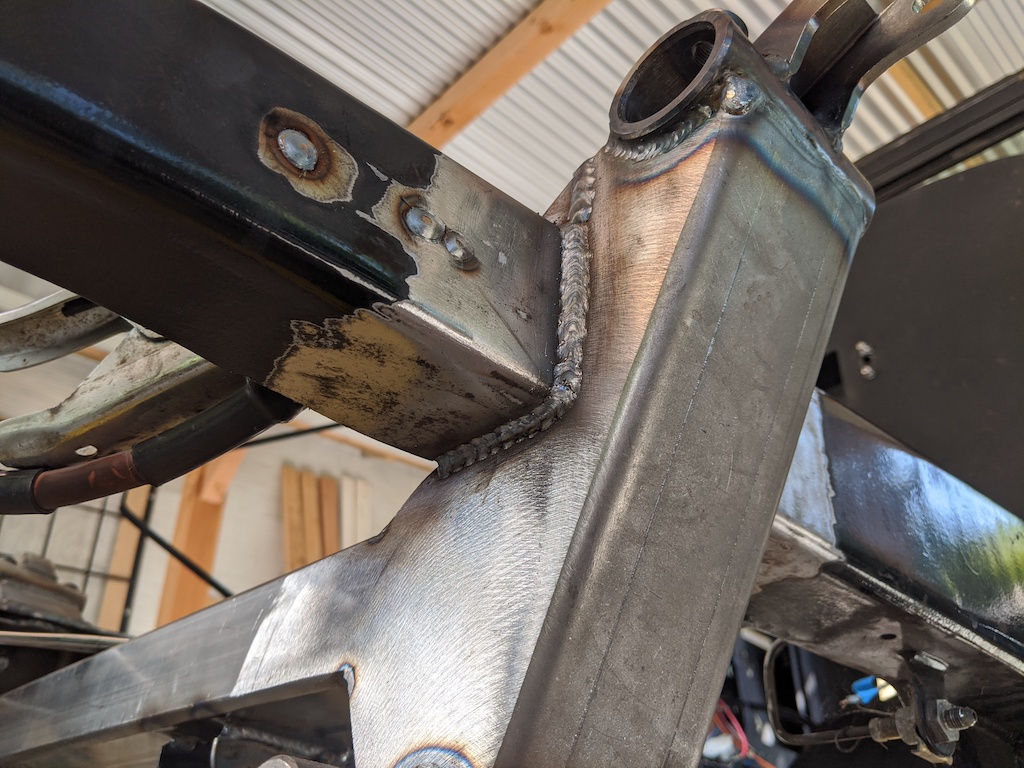

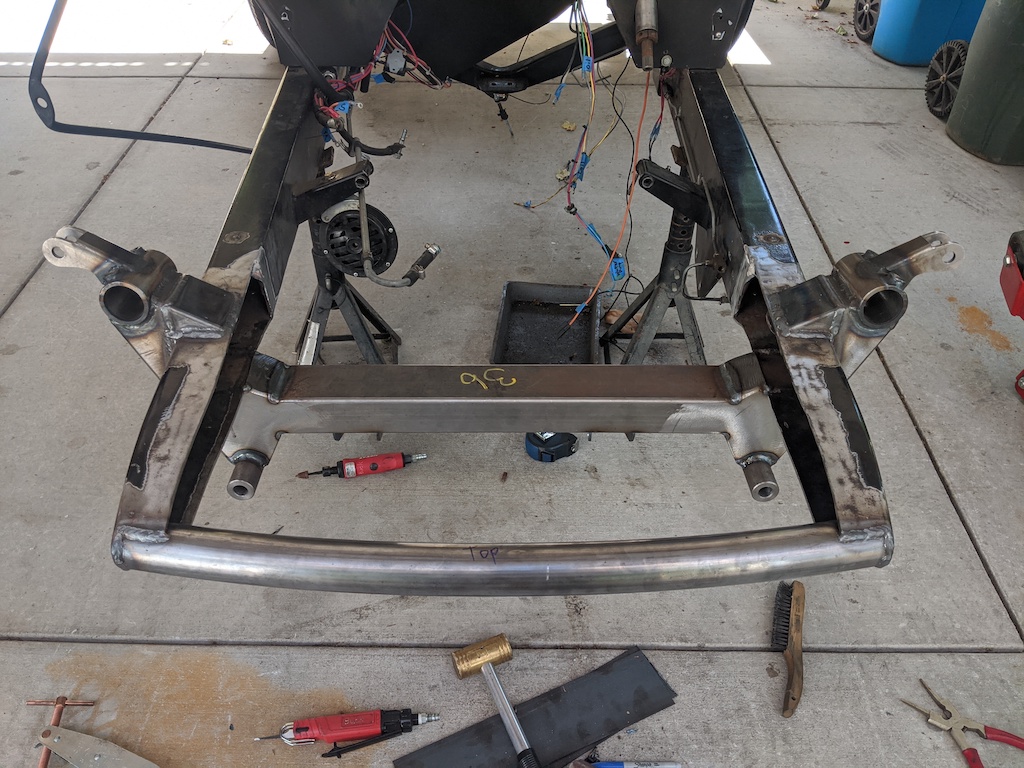

That's the plan! It needs some modifications done though, apparently the guy who used to own it was considerably smaller than my neighbor, so it needs a new cage

. (did you hear he died!?)

. (did you hear he died!?)