Couple photos and notes from the past week; I'm going to the 1000 so won't be working on the buggy for a week and don't want to forget anything.

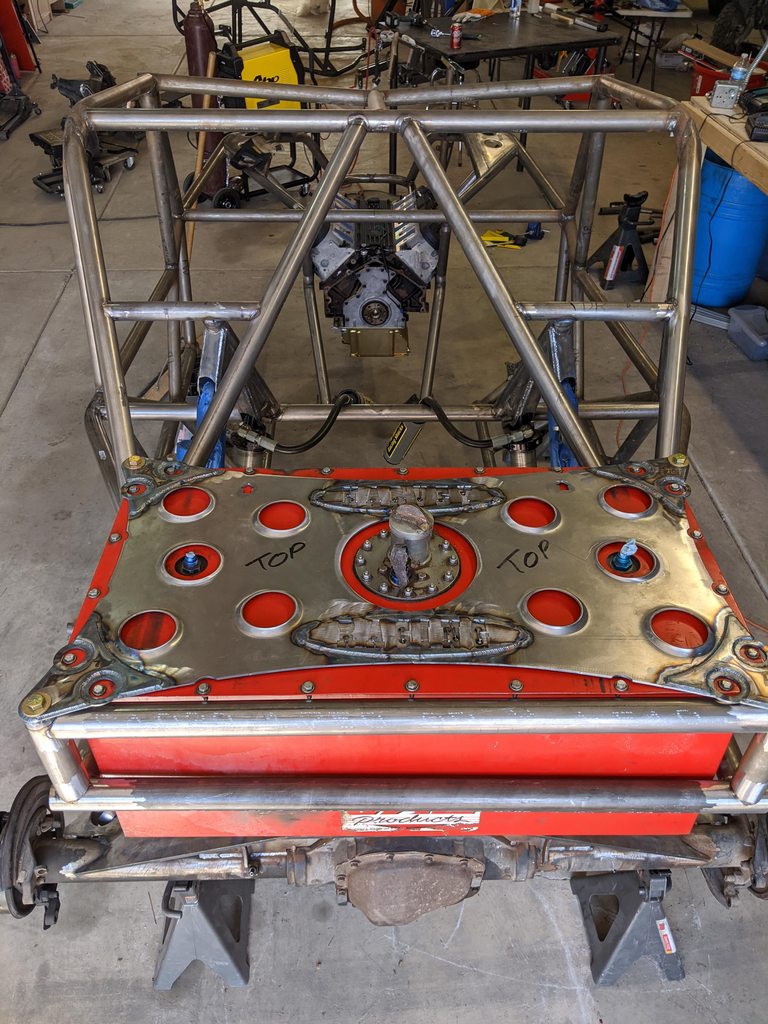

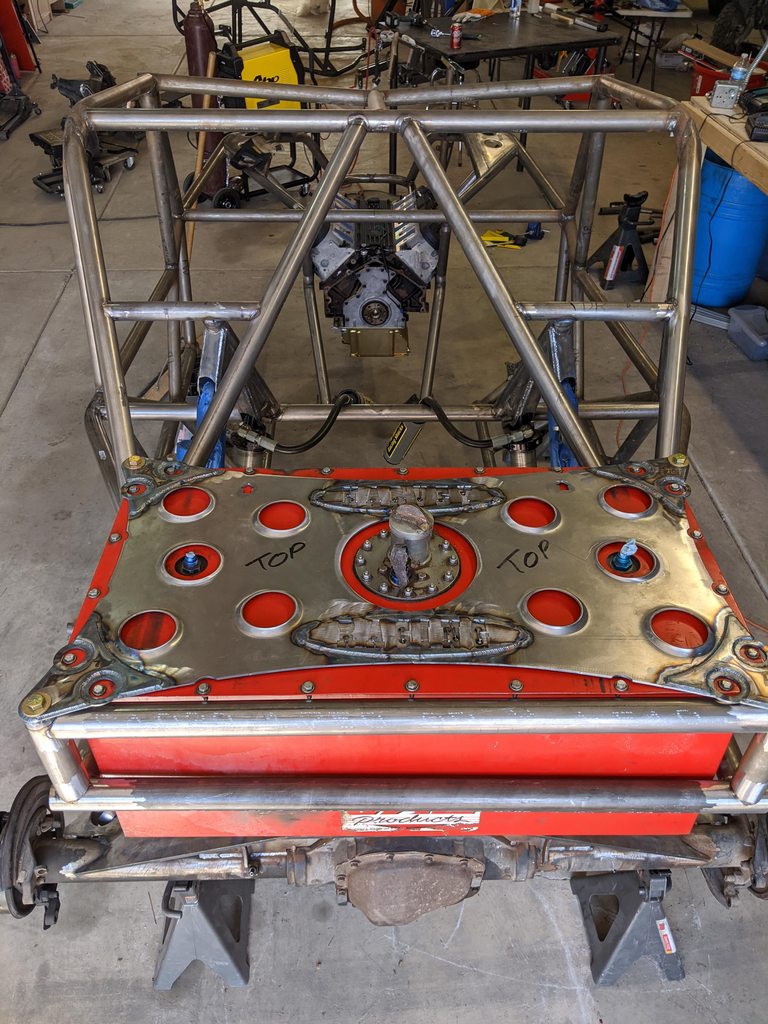

Got some 97 octane gas, which I put 10 gallons in the fuel cell. I'm not sure I need 97, I should have around 10.7-10.8 compression which is around LS3 levels and people run those with LSAs on pump gas, but I figured better to be safe and eliminate that variable for when I first start it.

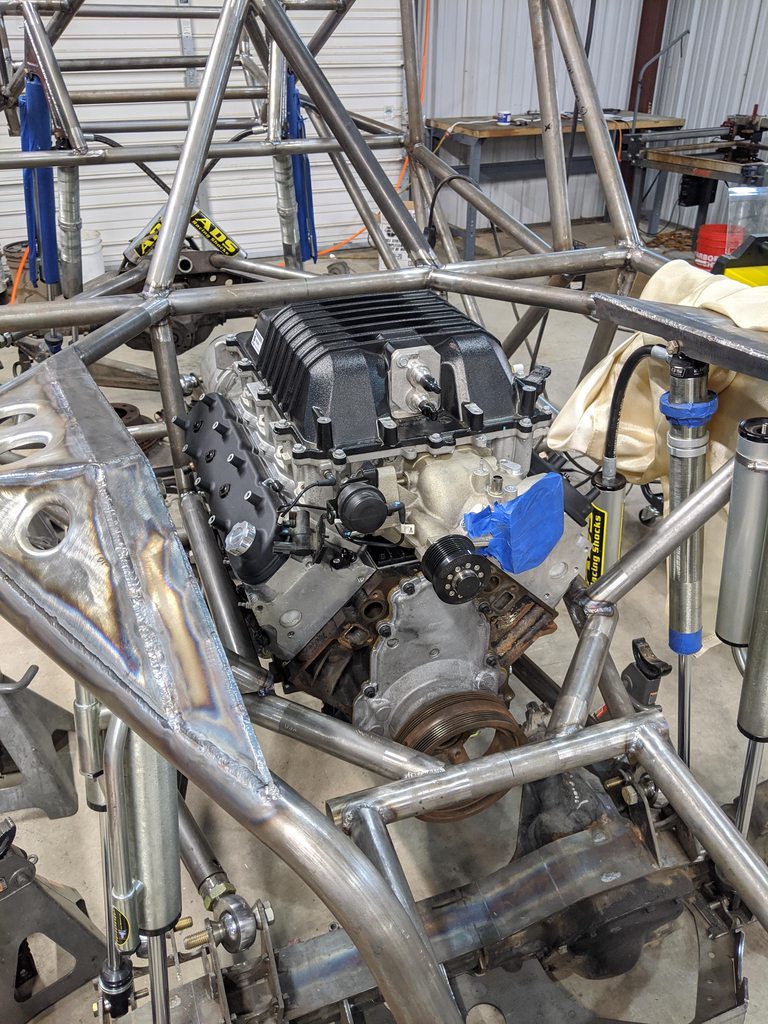

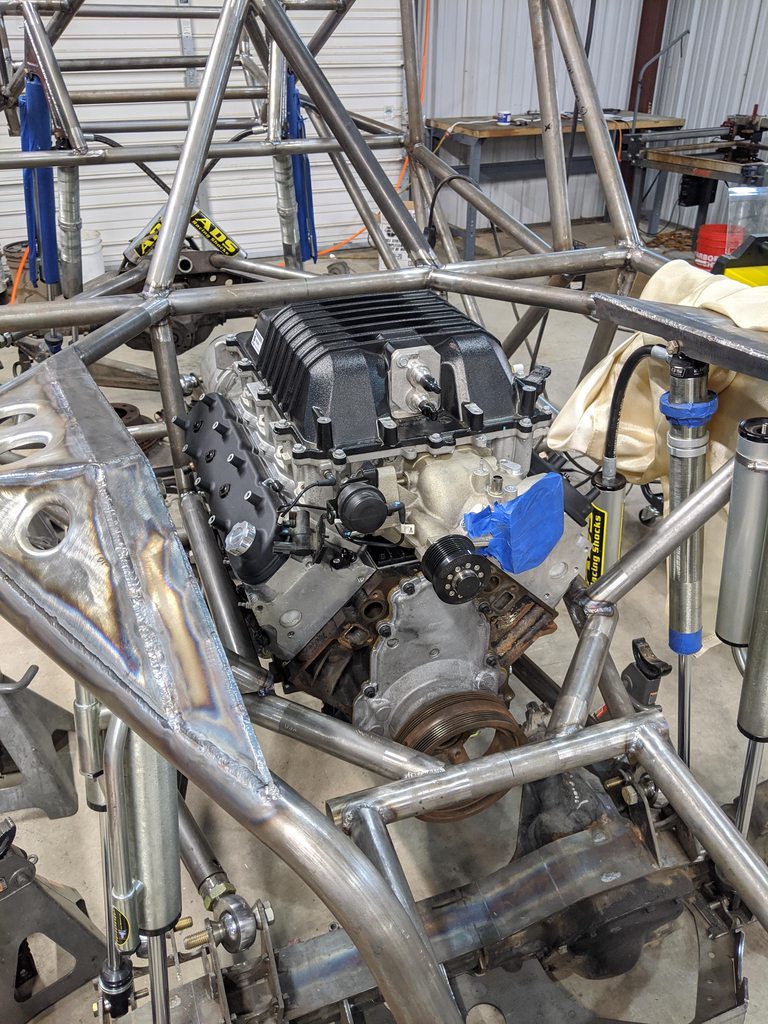

This is what my janky exhaust on both sides looks like. Drivers side has the O2 sensor. In the gauge setup there's a selection for left and right afr, I'm not sure if I can add another O2 sensor, I thought that was limited to the Holley Dominator and not the Terminator X that I have but the software seems to think I can. Might do that down the line. Once I get the firewall built obviously I'll have to make custom headers. These are actually a lot quieter than I thought they'd be, I've only taken the engine to 4000rpm once and she was definitely screaming but with helmets/headsets and behind a firewall it'd definitely be okay. I got a video of revving it up and of course the audio was flattened out so it sounds the same the whole time -_-

I'm running Amsoil Break-In oil and have 10w-30 dominator racing oil ready to replace it. Their literature is slightly confusing, sounds like it can break the engine in within 30 minutes but they advertise to run it for a few thousand miles? I'm thinking I'll leave it in until I tune the engine and then swap it out. The transmission just has cheap valvoline atf since it's essentially stock and I expect to replace it eventually. The atlas has Redline extreme shock which came with it.

Obviously the wiring is a complete cluster. To make matters worse some of the plugs are on the wrong side of the engine since the LSA has different locations than the stock intake obviously. The fuel pressure plug flat out can't reach unless I unplug four other sensors. I ordered extensions for the fuel pressure and MAP which is hopefully all I need. I think it should be easy to pretty it up. Biggest concern is the VSS off the atlas is literally right below the shifters and above the output flange, so that will need some creativity to keep the harness safe.

Mockup location for the steering reservoir. Not a fan of having it here, but it needs to at least be this height and since the chassis dips at the windshield this is arguably the most protected location since it's the highest point of the hood. Also best routing of the hoses. I'll have the fluid cooler and the supercharger intercooler mounted above the winch. Probably add a little bar or just the shock cross brace to protect it in a rollover. The reservoir didn't come with any mounting hardware, and I drew up both a plate and a billet mount in CAD but have yet to really decide which route to go, probably do the billet mount since a plate mount sounds ugly but that's a lot more work so I didn't do it yet. I have all the hoses and most of the correct fittings (couple I want to change out) for the steering. I ended up just ghettoing it together with the orbital looping back on itself and the reservoir hooked up the pump wouldnt starve. Next step is mount the reservoir and orbital and then the steering will be done though.

Here's my janked battery setup. I have a starter switch, a trans switch, and ignition. It's actually simpler than I thought it'd be so it should be easy to simplify everything into the chassis. ECU will be mounted behind the dash I'm thinking and the battery will be behind the seats.

Finally engine notes and observations. First I about had a heart attack since I couldn't build oil pressure. I wanted oil pressure, then move the harness so I could read fuel pressure and make sure I had both, then hook up the coil packs. I cranked the engine for like a minute and no oil pressure. I read stuff and watched videos, pulled the oil cooler lines, pulled the filter, added another 3 quarts of oil (it had 6 quarts since it's a 6quart pan, but then has a rear mounted oil cooler, the pan is aftermarket, the dip stick is aftermarket, I had no idea how much it really needed), pumped as much oil into the pump priming port as possible, etc. and FINALLY I cracked the oil cooler line at the base and it was starting to get oil. Turns out to get oil pressure it has to pump oil through the entire 20ft of oil cooler lines. Of course I had lubed the shit out of it with assembly lube when I built it, but that was like 7-9 months ago. Huge relief when it started showing pressure.

Like I said I put 10 gallons of 97 octane in, I didn't touch the regulator but the system primed to 45psi right away. I've had lots of fuel issues in the past, so that was a big relief. No leaks anywhere.

Put the spark plugs in and plugged everything in and she fired right up without hesitation! I'm using one of the base tunes on the Holley handheld, no idea how close it is but it's close enough to fire up. Subsequently it had issues going, I ultimately set the throttle body to 5% open and it seems to consistently fire up now. I'm not sure if that's what I should leave it at in the future, or I can tune it to have the butterfly totally closed (I mean it did start the first time totally closed).

Now onto "issues". There were a handful of coolant leaks. Amazingly all but one of the 14 hose clamp connections held fine. The one straight off the pressure side of the water pump eventually burst. I ended up double clamping it since I didn't have any tighter fancy hose clamps. The radiator drain valve leaked and needed to be tightened down. And then a fitting for the vent line that I welded to one of the cooling tubes has a pin hole leak. The steam vent lines actually work out well since they're the highest point on the engine so I can crack those to get air bubbles out at the engine.

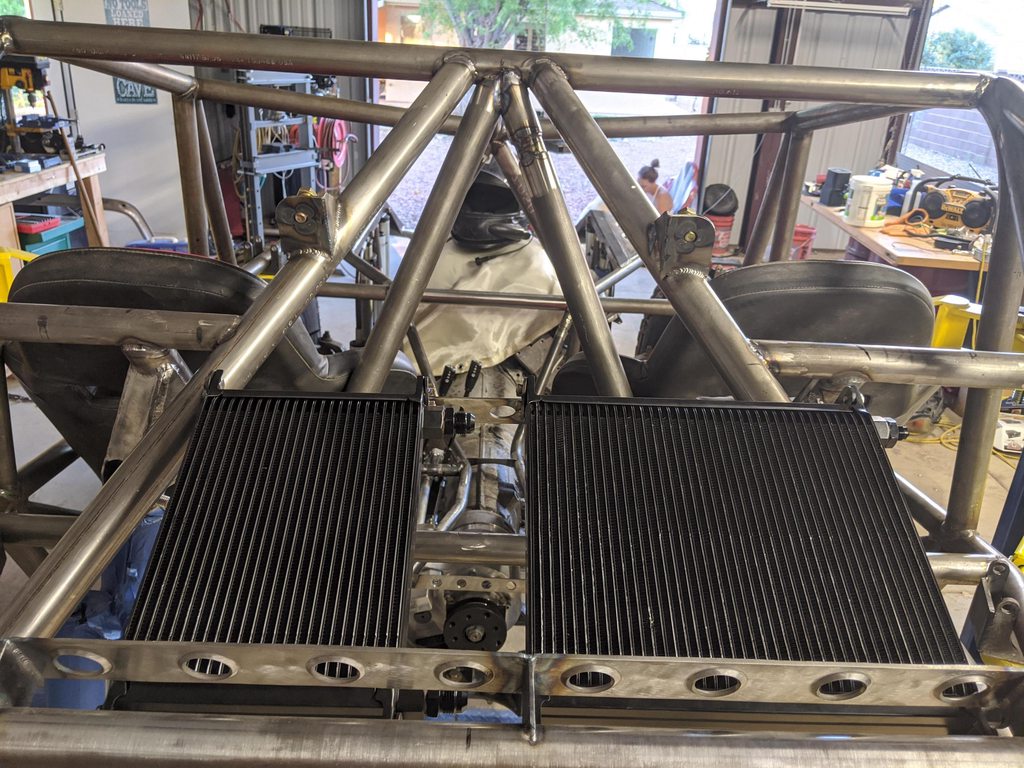

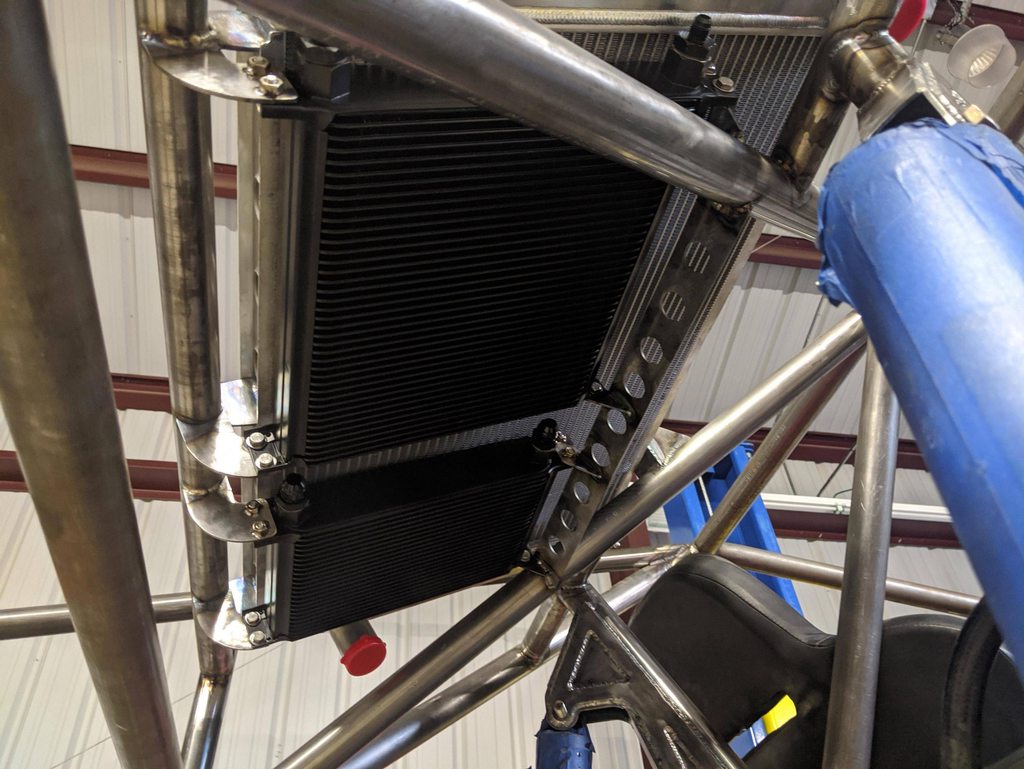

The engine warms right up, I added a thermostat by welding a housing to the first cooling tube, so it's water pump, rubber hose, then into thermostat housing and first aluminum tube. It appears (feels) to be working correctly. I have a 160 and a 180 degree thermostat, for now I just have the 180 in. Though this leads to the next issue, at idle the engine gets pretty hot. There's lots of possible reasons for this (and by hot, I mean it hits 220 and then I shut it down). If I rev the engine the temperature seems to fall too. I had a shop fan sitting on the radiator pulling air through, so that's not a lot of airflow but the cool side of the radiator is also considerably cooler than the hot side so it's doing a lot of work however more airflow could help. I'm also not sure all the air is removed from the engine, seems like every time I crack the vent line there's some air let out for a few seconds before coolant comes out. We also know the cooling system isn't holding pressure since that one weld isn't fully sealed. I could also remove the thermostat, though I think that's as likely the issue as the radiator not having airflow since the thermostat is obviously open.

Other issues, the oil cooler lines to the oil pan don't seem to be sealing. It's a lingenfelter oil cooler adapter and all new AN-10 fittings so not sure what the deal is there. I tightened the shit out of them and it's still dripping a bit.

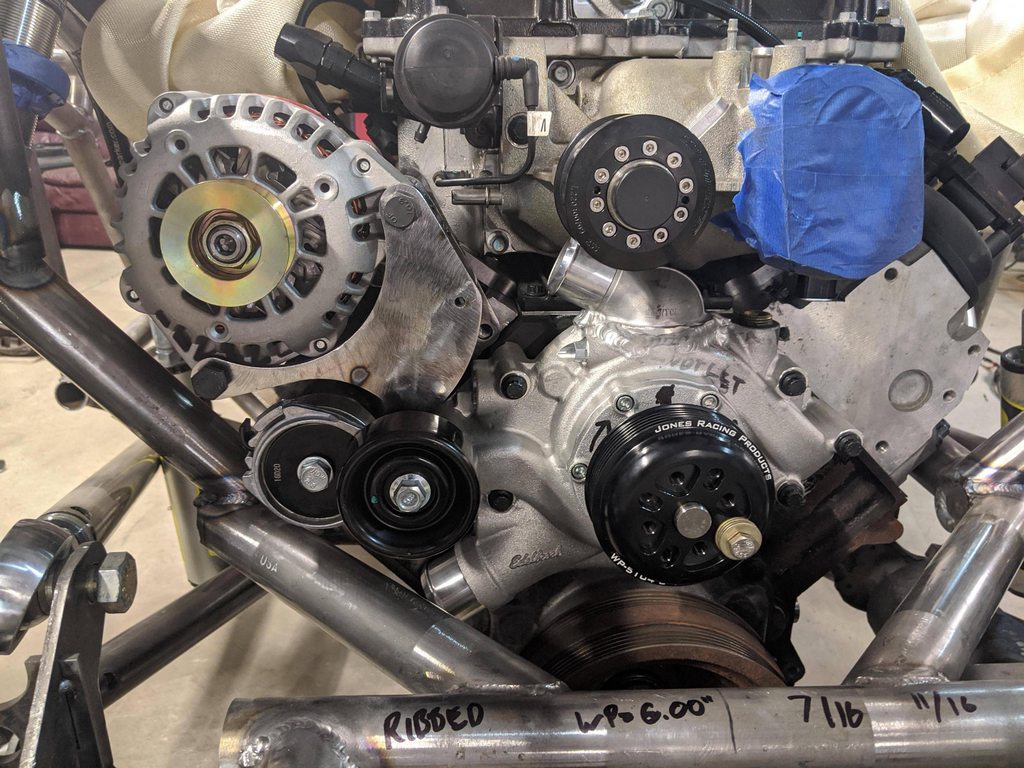

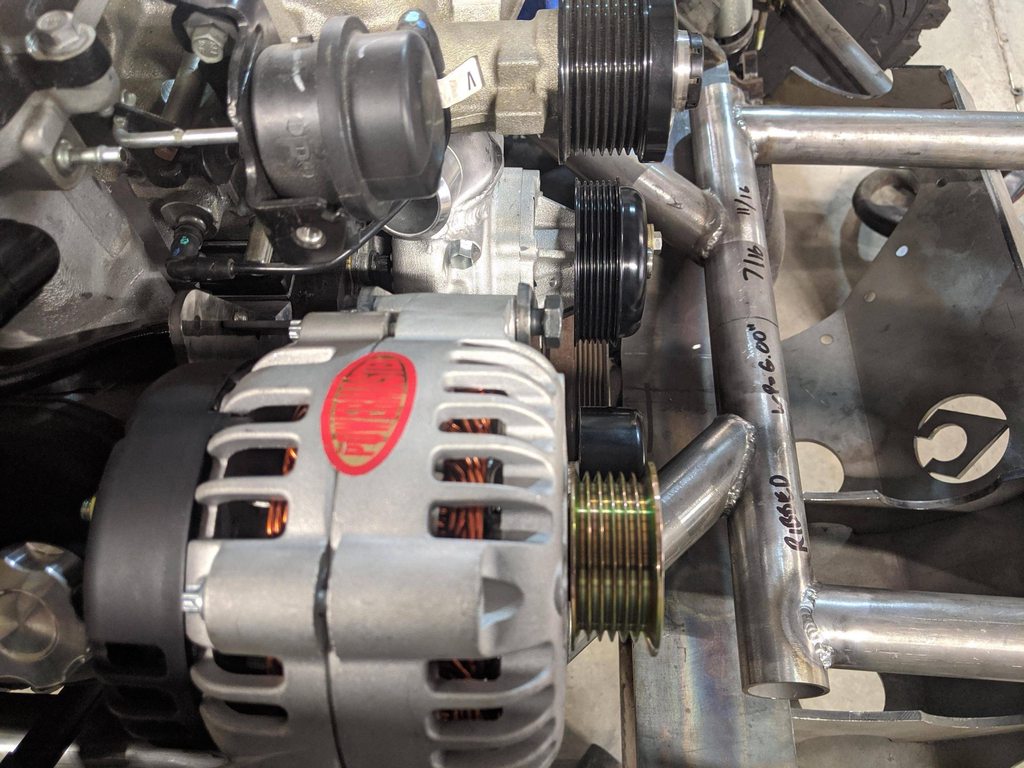

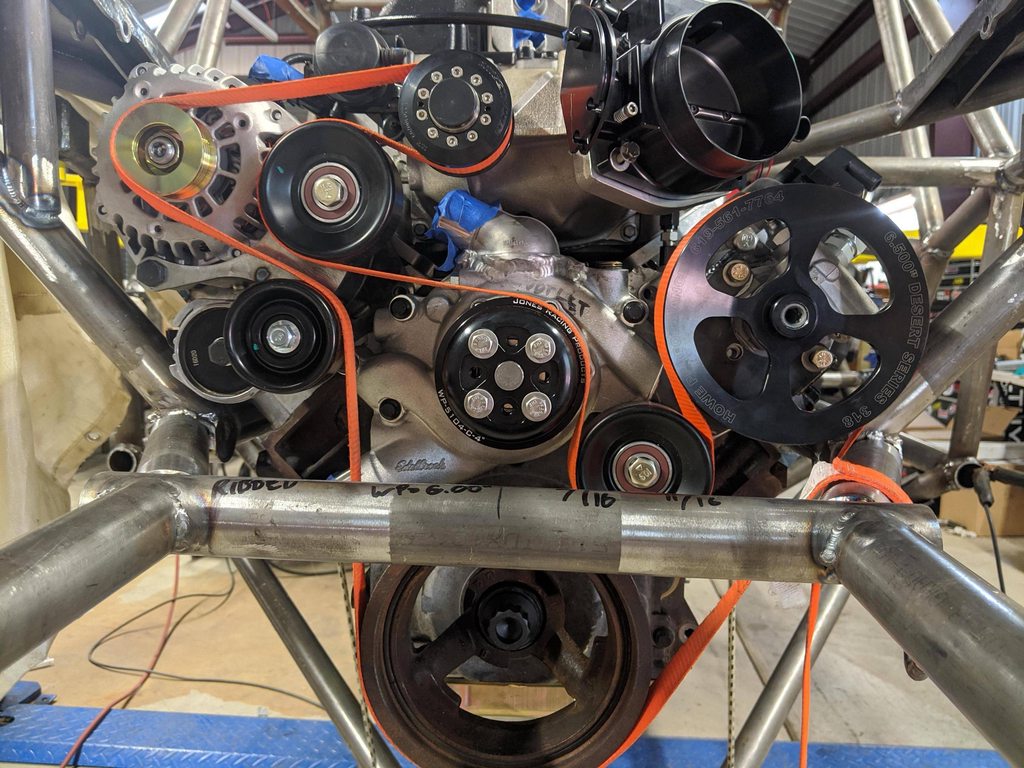

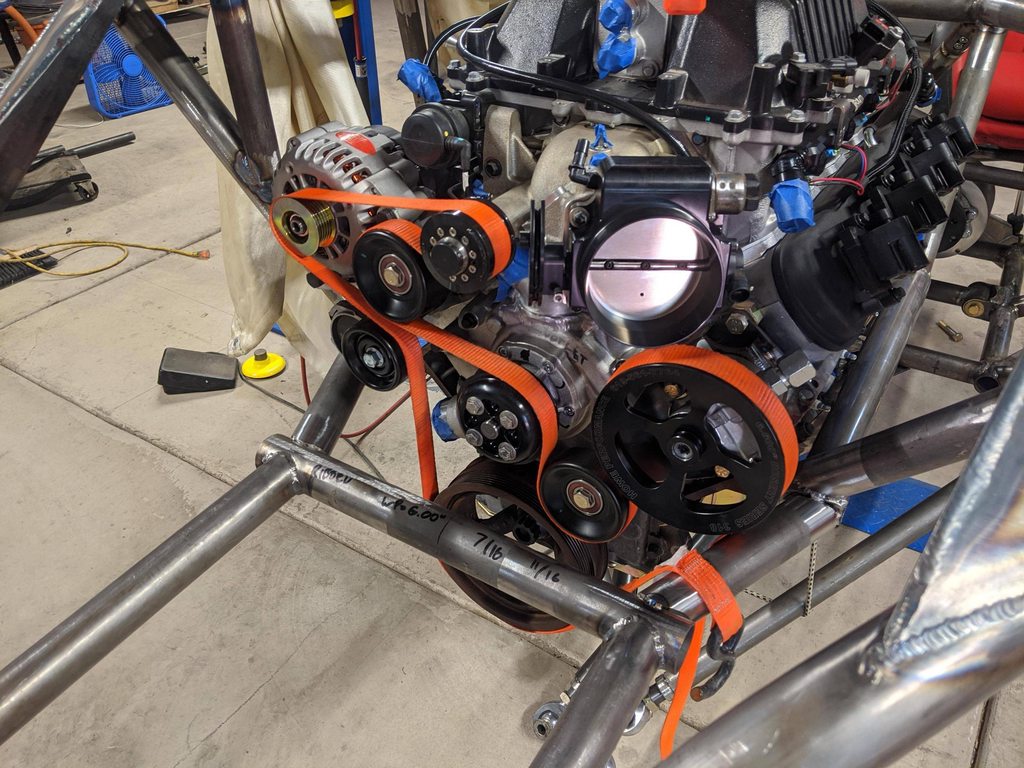

I had the serpentine come off twice, but I moved the belt to the rear grooves on the supercharger pulley (it's a 6 groove belt but an 8 groove pulley) and it hasn't come off since. I'm actually amazed it worked at all, and now more amazed it's still working at all considering all the accessory hook ups I made and welded and I'm sure are a few degrees off of parallel with each other. Time will tell if the rear groove solves everything.

The ecu is obviously trying to learn and I've only run the engine for maybe 15 minutes total, but it wont hold idle so far. I'm not sure if it's getting blower surge or its a combination the cam. The rev up frequency is probably every 3 seconds or so it'll rev up to like 1100rpm and then the ecu tries to compensate and it drops to like 600rpm and then revs back up. I'm sure I can correct this in the tuning but not sure how to do that yet.

I think that covers all my mental notes from yesterday of things that need to be addressed or concerned about. I've taken the engine to 4000rpm and she sang the whole way. I'm really stoked how well it seems to be working. This was the first v8 I've really delved into, and I tore it completely down to the crank and everything besides the rotating assembly and block is new so it was an adrenaline rush the first time it roared to life. Hopefully it stays together!

Next up is dialing in the engine a bit more so it's happy and I can let it run for a long time without issue, then finalize steering, then it's onto interior, brakes, and driveshafts and she'll be ready for some test drives! Lots to do, but they all feel easy compared to getting this done!