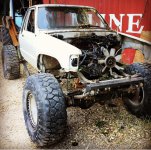

I started a “New” project and thought it was a good time to get a build thread going. I actually started this build in 2017. It was going to be a basic bobbed bed and dove nosed Toyota with all Toyota stuff. The build was cut short, I wanted to wheel and found a Toyota I could just bolt all my parts into to get back on the trail. Now that all of my parts are in a trail rig this build started to get more interesting.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Operation: Slug Nutz

- Thread starter Poopyota

- Start date

So fast forward, after many conversations with a one of my good buddies that’s helping me build the truck. We decided junkyard steering 14Bolts in a poop yota would be pretty fun! So how do you do it on the cheap? Dana 50’s don’t really have any value but have 60 outers. Is the 05+ SD stuff better? Probably but it’s going up in price as well, this build is supposed to be outside of the box and on the cheap so let’s see what happens! My buddy had a Dana 50 laying around and I had a 14Bolt from a project that never happened so the hunt was on for another Dana 50 and 14 Bolt

Then it came to taking some measurements and chopping up the 14 Bolts. We wanted to make the axles as wide as possible. We didn’t want to retube the housings. What we decided is for the front, the piece of tube that we cut off off the passenger side we would machine a sleeve for the inside and press it in, plug weld it and weld the seam. I’m theory we thought if we cut the spindles off in the same place on both axles and reused the cut off from the front for the driver side, both axles should have the same amount of tube. Which in finished form should have the same WMS. As it turns out there are variations in 14 Bolts, the one we chose for the front had welded on spindles and the one we chose for the rear had friction welded spindles. The friction weld was really large on the inside and would interfere with the axle shafts. We ended up having to cut off an additional 1/2” per side to remove the friction weld.

Attachments

ShitBoxSam

Well-known member

- Joined

- Aug 8, 2022

- Member Number

- 5432

- Messages

- 80

i like where this is goin!

Next step was to machine the inner C’s to press onto the 14 Bolts. The Dana 50’s use a larger tube than the 14 Bolts. When I cut the C’s off I left enough tube to chuck it into the lathe. We used a boring bar and went deeper than the part of the C that we were using. After all of the machining, we cut the remainder of the tube off and left part of the weld that is holding the thin sleeve that was the original axle tube.

Attachments

Thanks mani like where this is goin!

To machine the C’s and the sleeve we stamped all of the C’s and housings. Then made a story board. All of the tubes had slight variation’s especially the front housing. The tubes weren’t quite round.

Attachments

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,466

Plans to run 14 bolt gears in reverse up front?

YotaAtieToo

Thick skull

Wat?Plans to run 14 bolt gears in reverse up front?

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,466

Won’t 14 bolt gears up front need to be going the opposite direction for a passenger drop front axle?Wat?

YotaAtieToo

Thick skull

Won’t 14 bolt gears up front need to be going the opposite direction for a passenger drop front axle?

Again, Wat?

No, nothing changes.

Just like how a Toyota 3rd works the same weather it's in the rear or front.

McBastard79

Badical

- Joined

- May 20, 2020

- Member Number

- 681

- Messages

- 200

Man, this is dope!

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,466

I r dumb.Again, Wat?

No, nothing changes.

Just like how a Toyota 3rd works the same weather it's in the rear or front.

Thanks man!Man, this is dope!

YotaAtieToo

Thick skull

Might want to get that front under the truck before final welding, looks like the driveshaft will be eating the oil pan.

Thanks for the input! The axle is in the mock up stage with just heavy tacs currently. The photo of the axle might be a little deceiving, the axle is pretty wide. It might look like the diff is pretty far over but I think it’s the longer than normal short side tube that makes it look that way. The WMS is 73”. I’m trying to post the build in order, I haven’t posted much on what’s done to the truck yet, but I’m not running a conventional Toyota front spring setup and my motor isn’t in the factory location. Here is a photo of the oil pan circled in red with the axle under the truckMight want to get that front under the truck before final welding, looks like the driveshaft will be eating the oil pan.

Attachments

YotaAtieToo

Thick skull

Gotcha, wider wms definitely makes it deceiving.

Awesome that you're doing 4ws 14 bolts on leaf springs BTW

Awesome that you're doing 4ws 14 bolts on leaf springs BTW

Opiebennett

XJ_Ranger

My buggy is 74" outside of tire!

chaplinfj60

Well-known member

this is fucking back ass on so many levels. this is the ignorance of me coming out, i know the 14 uses the same size of shaft but different spline count than dana 60, is this a simple custom axle shaft order from dutchman or something? or is there some more magic?

YotaAtieToo

Thick skull

14b is a hair bigger, so yes, custom order.this is fucking back ass on so many levels. this is the ignorance of me coming out, i know the 14 uses the same size of shaft but different spline count than dana 60, is this a simple custom axle shaft order from dutchman or something? or is there some more magic?

chaplinfj60

Well-known member

still dam cool axle

Thanks manGotcha, wider wms definitely makes it deceiving.

Awesome that you're doing 4ws 14 bolts on leaf springs BTW

This thing is going to be all business not really any bling parts in this build

This thing is going to be all business not really any bling parts in this buildYes, custom axles from Branik. These are just Dana 60 blanks with 14 Bolt 30 spline and he sells 35 spline 99-04 stub shafts with a puck to mate to the unit bearing.this is fucking back ass on so many levels. this is the ignorance of me coming out, i know the 14 uses the same size of shaft but different spline count than dana 60, is this a simple custom axle shaft order from dutchman or something? or is there some more magic?

Attachments

chaplinfj60

Well-known member

wow is all i got this is so cool. for the rear, are centered or off set?

Thanks man! The pinion is in the center, so there is a long side and a short side axle shaft.wow is all i got this is so cool. for the rear, are centered or off set?