Treefrog

Book Wheeler

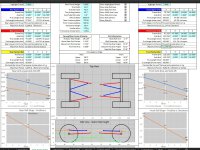

The second one looks like the better option. Might want to try shortening the upper links, it will probably help with the pinion angles. Raising the panhard up will take the front and body roll slopes towards understeer if you feel the need.It’s mainly for rock crawling, AOP. May see the road going to the gas station and such. It’s a tj on tons. I did 2 different locations for upper link on the frame and have both. The unsprung weight is a guesstimate, I can’t tell what the cage is made of, looks store bought.

There is some info in here regarding the top view angle of the links for 3 links.

Highlight travel is probably your friend here. The numbers had their advantage, but I found that they hid what was actually going on, and with the increase in data points it wasn't feasible to stick with them. And with the next version having the ability to do way way more data points, they won't be returning. That said, any suggestions for improving it like adding a second highlighted travel, I am all ears.

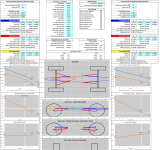

Highlight travel is probably your friend here. The numbers had their advantage, but I found that they hid what was actually going on, and with the increase in data points it wasn't feasible to stick with them. And with the next version having the ability to do way way more data points, they won't be returning. That said, any suggestions for improving it like adding a second highlighted travel, I am all ears. What about having Imperial / Metric on split worksheets that work off a times or divide formula? Probably a waste of time considering most will be working in their preferred measurements though.

What about having Imperial / Metric on split worksheets that work off a times or divide formula? Probably a waste of time considering most will be working in their preferred measurements though.