kmkommes

Red Skull Member

- Joined

- Mar 18, 2021

- Member Number

- 3686

- Messages

- 17

I should be reading through the “unfinished projects” thread but my ADD started this instead.

Let’s make things more complicated than they need to be.

I’ve read a few kitchen threads here and against better judgement I’m still planning on the DIY option.

My desire for quality and budget doesn’t support the box store or a custom solution.

I looked at RTA. I was heavily leaning towards Barker Cabinets. I priced them and was at about $10,000 in just unfinished cabinets. Additionally, I would have to trim out the cabinets, build refrigerator encloser, and an island, etc. Barker cabinets are made and sourced in the US. They have a sister company citycabinets which is a cheaper due to globally sourced materials. I could look into them but that would sway me away from DIY and I don’t want that to happen. Yes there are cheaper RTA options but I've already made up my mind.

After staring at RTA cabinets and watched too many youtube videos I came to the conclusion cabinets aren’t all that hard to make. So that’s my plan. At first I was thinking of building boxes and buying the drawers and door. Then I decided to build drawers. Now I am thinking doors wouldn’t be that bad either.

I understand this is going to take me longer and cost more and quality is a big unknown. But I will have additional tools and an experience. I love teaching others by making my own mistakes.

Decisions

Layout:

Design/Construction:

Materials:

Tools:

Please add your thoughts below so I can ignore them, especially if you are in the cabinet or wood business.

Let’s make things more complicated than they need to be.

I’ve read a few kitchen threads here and against better judgement I’m still planning on the DIY option.

My desire for quality and budget doesn’t support the box store or a custom solution.

I looked at RTA. I was heavily leaning towards Barker Cabinets. I priced them and was at about $10,000 in just unfinished cabinets. Additionally, I would have to trim out the cabinets, build refrigerator encloser, and an island, etc. Barker cabinets are made and sourced in the US. They have a sister company citycabinets which is a cheaper due to globally sourced materials. I could look into them but that would sway me away from DIY and I don’t want that to happen. Yes there are cheaper RTA options but I've already made up my mind.

After staring at RTA cabinets and watched too many youtube videos I came to the conclusion cabinets aren’t all that hard to make. So that’s my plan. At first I was thinking of building boxes and buying the drawers and door. Then I decided to build drawers. Now I am thinking doors wouldn’t be that bad either.

I understand this is going to take me longer and cost more and quality is a big unknown. But I will have additional tools and an experience. I love teaching others by making my own mistakes.

Decisions

Layout

Design/Construction

Materials

Tools

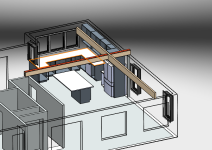

Layout:

I’m going to screw this up. We didn’t like our previous layout. This one may not be any better. It’s an expensive risk we are rolling with.

Design/Construction:

Frameless: 3/4 plywood with solid edgebanding of unknown thickness

BLUM hinges and undermount slides.

Materials:

Wood....

Paint finish

Tools:

I’m trying not to go full retard on this but I did order a the Festool TS 60 track saw and have been eying up a SawStop table saw.

$2000 to $7000

The kitchen is a big project. I have a lifetime of other ideas of stuff to build.

Please add your thoughts below so I can ignore them, especially if you are in the cabinet or wood business.