rattlewagon

shitboxin

First bit of this is on the other site, but didnt miss much.

Super low budget truck. A buddy bought as a motor donor, came with a marlin 10* doubler and a bunch of other rando parts about 2 years ago. . Now its stock on 35s with the doubler and hand rail bumpers. bad body rust, solid frame. EMT exhaust, zero leaf spring bushings, broken leafs in each pack I have about 10 acers that it lives on, 1/2 feild 1/2 woods. And this truck is awesome for quick hot laps through the woods. Truck is such a blast. Hes been slowly collecting parts and were slowly moving towards solid axle.

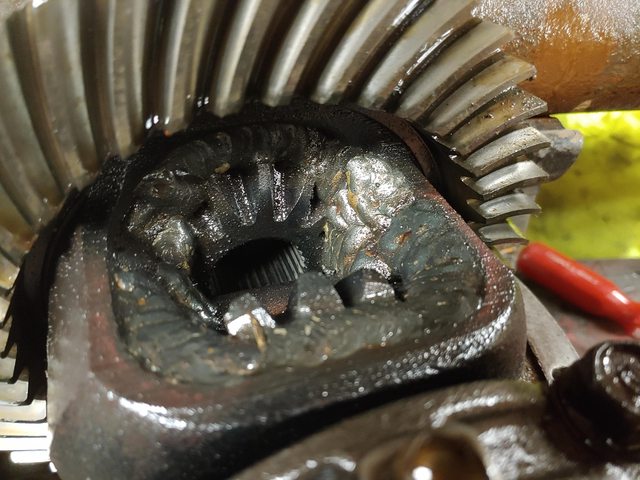

Where were at now: Trunions are just about done, rest of the axle will go together soon. Just basic SA hubs with wheel spacers. nothing fancy.

These cost as much as the whole truck

Super low budget truck. A buddy bought as a motor donor, came with a marlin 10* doubler and a bunch of other rando parts about 2 years ago. . Now its stock on 35s with the doubler and hand rail bumpers. bad body rust, solid frame. EMT exhaust, zero leaf spring bushings, broken leafs in each pack I have about 10 acers that it lives on, 1/2 feild 1/2 woods. And this truck is awesome for quick hot laps through the woods. Truck is such a blast. Hes been slowly collecting parts and were slowly moving towards solid axle.

Where were at now: Trunions are just about done, rest of the axle will go together soon. Just basic SA hubs with wheel spacers. nothing fancy.

These cost as much as the whole truck

keep up the strong work.

keep up the strong work.