AgitatedPancake

Frobot

Let's cut and splice some cylinder heads.

This should be fun. It's just a personal project that I'm chipping away at on the back burner, so it'll be very slow but it has some pretty spicy potential. If it all works out I may make a handful as there have been some pretty interested people.

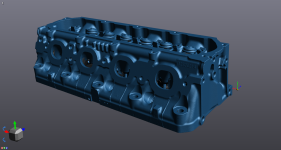

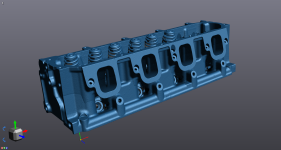

I've got a set of L83 (Gen V 5.3 LT truck motor) cylinder heads that I'm going to cut and splice onto a jeep 4.0 and stuff with boost.

The 4.0 is actually a surprising platform, as people are pretty comfortable stuffing 10+psi of boost into a completely stock still sealed long block and keep them alive with great success. With ARP head studs and forged pistons people push things closer to 20PSI and the 500HP ballpark. There have been a few 600hp builds, and the record as of now peaked above 800HP. But all of that is done with massively limiting reverse flow heads with the intake and exhaust on the same side. People run larger LS valves and port the heads for decent flow numbers, but the platform is essentially tapped out flow wise. So adapting a modern cross flow head will unlock the next level of potential for a 4.0, and I believe could help it break the 4 figure HP barrier or break parts trying.

Bore spacing:

4.0 - 4.38"

LS/LT - 4.4"

Bore diameter

4.0 - 3.875"

L83 - 3.78"

Lifter bore spacing:

4.0 - 2.02"

LS/LT - 2.2"

Jeep 4.0 stock head flow:

Intake - around 190-210 CFM depending on casting with 1.91" valve

Exhaust - around 140 CFM depending on casting with 1.5" valve

Jeep 4.0 average ported head flow:

Intake - 250-270 with 2.02" valves

Exhaust - 170-200 with 1.57" valves

L83 stock head flow:

Intake - 250 CFM wtih 1.928" valve

Exhaust - 180 CFM with 1.555" valve

L83 ported head flow:

Intake - 330 CFM wtih 1.928" valve

Exhaust - 210 CFM with 1.555" valve

They keep the valve size small to work with the small bore of the L83, with the extra 60 thou clearance to the bore in the 4.0, can't wait to see what it can do with bigger valves. But even before that, it's capable of more flow than the best ported 4.0 head out there that I'm aware of.

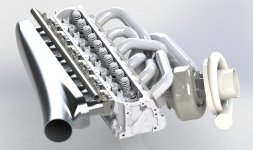

So the heads are getting lopped in the center and welded together, then I have to reposition one bank of head bolt holes to align the valves over the bores where I want them. Then a custom intake and exhaust, and turbo if I feel like getting wild. But the header is designed so it works well with NA builds as well.

This should be fun. It's just a personal project that I'm chipping away at on the back burner, so it'll be very slow but it has some pretty spicy potential. If it all works out I may make a handful as there have been some pretty interested people.

I've got a set of L83 (Gen V 5.3 LT truck motor) cylinder heads that I'm going to cut and splice onto a jeep 4.0 and stuff with boost.

The 4.0 is actually a surprising platform, as people are pretty comfortable stuffing 10+psi of boost into a completely stock still sealed long block and keep them alive with great success. With ARP head studs and forged pistons people push things closer to 20PSI and the 500HP ballpark. There have been a few 600hp builds, and the record as of now peaked above 800HP. But all of that is done with massively limiting reverse flow heads with the intake and exhaust on the same side. People run larger LS valves and port the heads for decent flow numbers, but the platform is essentially tapped out flow wise. So adapting a modern cross flow head will unlock the next level of potential for a 4.0, and I believe could help it break the 4 figure HP barrier or break parts trying.

Bore spacing:

4.0 - 4.38"

LS/LT - 4.4"

Bore diameter

4.0 - 3.875"

L83 - 3.78"

Lifter bore spacing:

4.0 - 2.02"

LS/LT - 2.2"

Jeep 4.0 stock head flow:

Intake - around 190-210 CFM depending on casting with 1.91" valve

Exhaust - around 140 CFM depending on casting with 1.5" valve

Jeep 4.0 average ported head flow:

Intake - 250-270 with 2.02" valves

Exhaust - 170-200 with 1.57" valves

L83 stock head flow:

Intake - 250 CFM wtih 1.928" valve

Exhaust - 180 CFM with 1.555" valve

L83 ported head flow:

Intake - 330 CFM wtih 1.928" valve

Exhaust - 210 CFM with 1.555" valve

They keep the valve size small to work with the small bore of the L83, with the extra 60 thou clearance to the bore in the 4.0, can't wait to see what it can do with bigger valves. But even before that, it's capable of more flow than the best ported 4.0 head out there that I'm aware of.

So the heads are getting lopped in the center and welded together, then I have to reposition one bank of head bolt holes to align the valves over the bores where I want them. Then a custom intake and exhaust, and turbo if I feel like getting wild. But the header is designed so it works well with NA builds as well.

Attachments

-

L83 - Head + Header 17.JPG131.4 KB · Views: 618

L83 - Head + Header 17.JPG131.4 KB · Views: 618 -

L83 Cylinder Head - Picture 3.png131.9 KB · Views: 157

L83 Cylinder Head - Picture 3.png131.9 KB · Views: 157 -

L83 Cylinder Head - Picture 1.png106.4 KB · Views: 145

L83 Cylinder Head - Picture 1.png106.4 KB · Views: 145 -

278668680_10159758626822612_985398630488192777_n.jpg96.4 KB · Views: 151

278668680_10159758626822612_985398630488192777_n.jpg96.4 KB · Views: 151 -

278618891_10159758626907612_2036098201645898138_n.jpg90.9 KB · Views: 150

278618891_10159758626907612_2036098201645898138_n.jpg90.9 KB · Views: 150 -

278588890_10159758626982612_7083498483330328374_n.jpg85 KB · Views: 144

278588890_10159758626982612_7083498483330328374_n.jpg85 KB · Views: 144 -

278549821_10159758626872612_6991174635155531843_n.jpg89.7 KB · Views: 146

278549821_10159758626872612_6991174635155531843_n.jpg89.7 KB · Views: 146 -

278548307_10159758626782612_9218689647626461259_n.jpg95.9 KB · Views: 157

278548307_10159758626782612_9218689647626461259_n.jpg95.9 KB · Views: 157 -

L83 - Head + Header 19.JPG237 KB · Views: 171

L83 - Head + Header 19.JPG237 KB · Views: 171 -

L83 - Head + Header 18.JPG181.2 KB · Views: 178

L83 - Head + Header 18.JPG181.2 KB · Views: 178

Last edited:

. Getting the IATs down will be a great bonus to all of this for sure!

. Getting the IATs down will be a great bonus to all of this for sure!