Wisconsinite

Red Skull Member

Here it is in the Goatbuilt booth, sitting next to Ian Johnsons LJ kit. I was lucky enough to go wheeling with him for a day. It got the juices flowing!

I think with the skid plates and engine cross member its right around 700 lbs.Nice work! Do you know what the bare chassis w/ skid plates weighs?

Drilling the holes was nerve wracking, let me tell you.

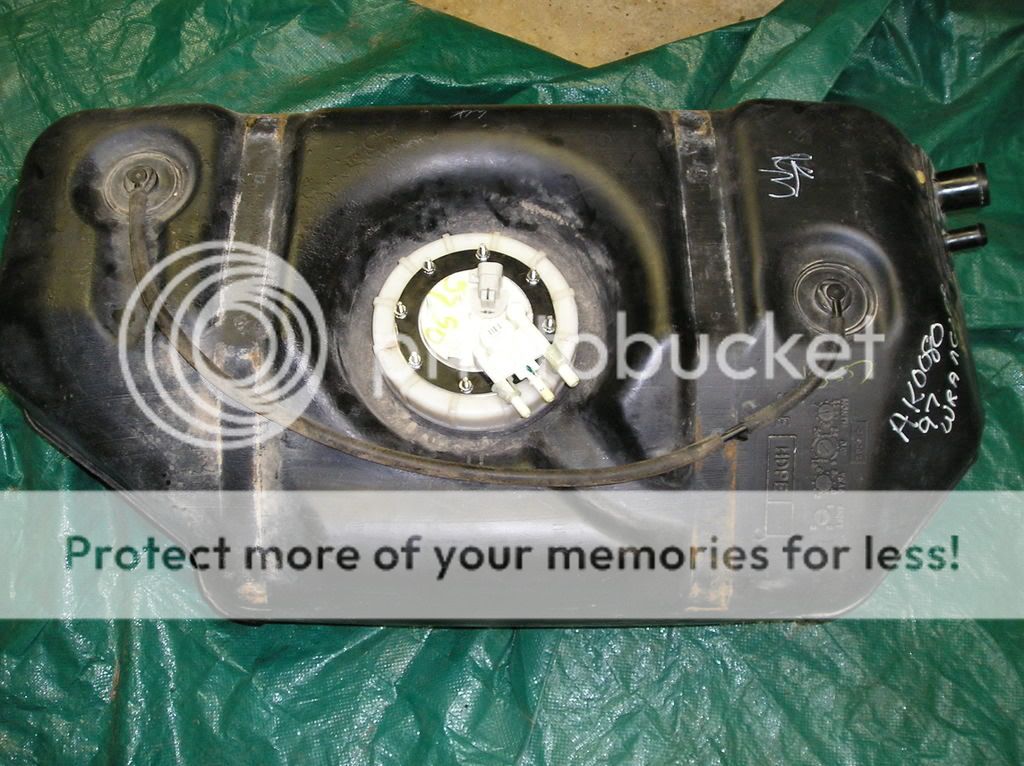

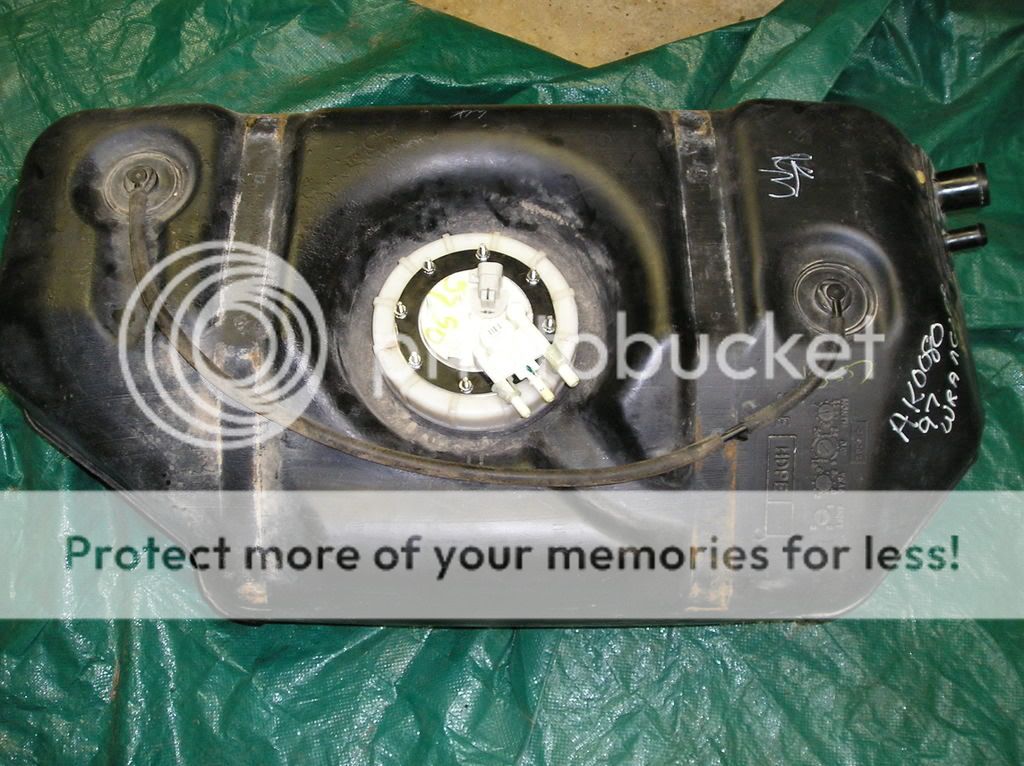

One last question, the fuel tank vent nipple is broken on this tank, and is not a replaceable component. Any ideas on a fix?

Do you drill out the whole fitting, like a 1.00" diameter hole? Then use a big washer or something? My mind can only come up with ghetto solutions.drill out and use a bulkhead?

Do you drill out the whole fitting, like a 1.00" diameter hole? Then use a big washer or something? My mind can only come up with ghetto solutions.

Do you drill out the whole fitting, like a 1.00" diameter hole? Then use a big washer or something? My mind can only come up with ghetto solutions.

The only issue I see with something like that, is I think there is a roll over valve or something in there. The triangle on top has something going on inside of it. I think the whole boss on the top might need to be removed. I have a few tanks floating around, I just kinda wanted to fix this one and keep the others as spares.

Bulkhead Fittings - Free Shipping on Orders Over $109 at Summit Racing

Find Bulkhead Fittings and get Free Shipping on Orders Over $109 at Summit Racing!www.summitracing.com

That has potential. However, the plastic is 24 years old and pretty brittle. I am not sure it would work, but it is worth trying first before I take a hole saw to it.Is it the white-ish plastic part on the left side of the last pic?

It looks like the nipple was coming out 90° horizontally. I would try carefully drilling and tapping the hole for something like a 1/8NPT thread, and running a barb fitting to the hose size you need. The hole would only need to be like 1/4" deep at most.

Edit: like this:

Epoxy the hole shut and add a AN8 bulkhead somewhere else ?

Edit : Add 2 bulkheads, one for vent and one for return.

Yes. The other one is in tact, I just figured there was a reason there was 2, so I should use 2.Doesn't the TJ tank have two vents that are teed together outside the tank? Epoxy the broken one shut and use the other as a vent?

The factory vent was .25" OD, and tiny ID. Do you think dual -6 would be adequate? Or go straight to -8? These will be routed to a catch can with ROV.The bigger the vent the easier it is to fill up. Don't go small on vent size.

One single vent will be easier to route, less fittings, simpler, less problems etc.

So yeah, I'd go with a single AN8 and be happy.

Also,

AN6 = 3/8 ID = 0.11in2 area

Dual AN6 = 0.22in2 area

An8 = 1/2 ID = 0.2in2 area

Close enough I'd say

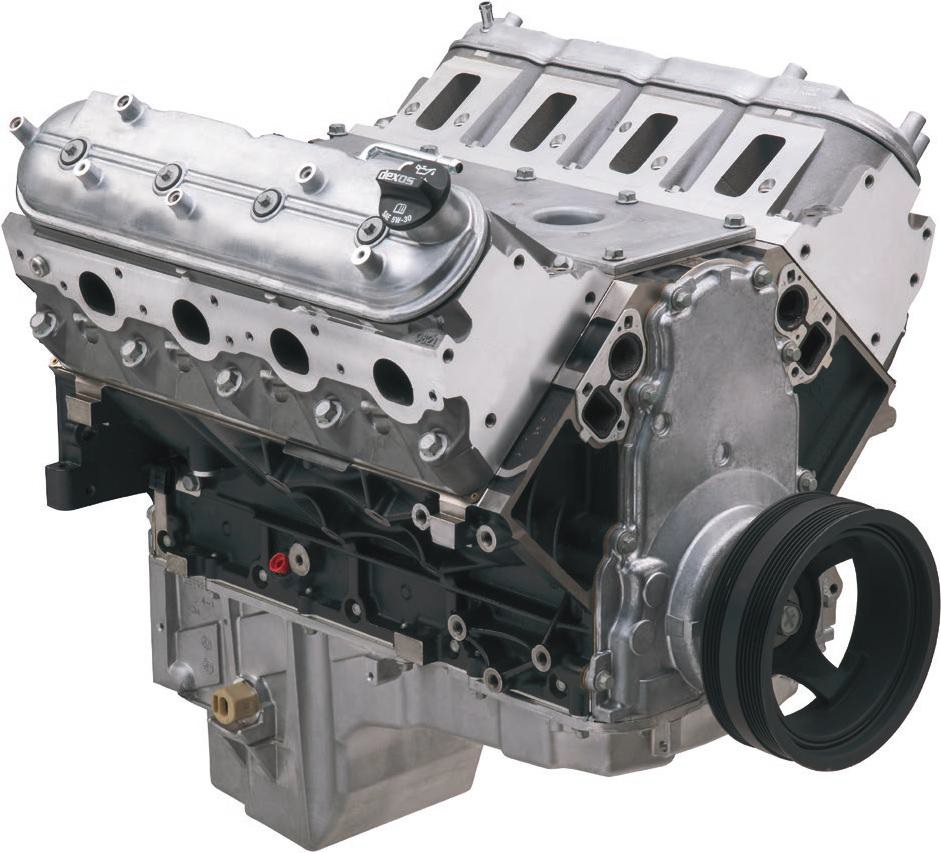

I would throw that stock fuel tank in the dumpster and drop in a GB fuel tank. Make a 2005 truck pump plate so you can use the in tank filter regulator and have a returnless system. You can also put your Walbro 225 pump into the stock housing for more output.

Make a new aluminum tank cover I assume a little bit taller and a bolt in riser kit for the existing side panels. Keep the same tank skid.

Why do you say that? I already have all the parts (minus bulkhead fittings) to get my tank and sending unit/pump assembly into the factory tank. That would also cut into my rear cargo area.

EDIT: Using our cell would make it very hard to install a clean remote fill.

vent size isnt a big deal unless you plan on racing and refueling in a timely matter is a big deal.

There are two vents from the factory. One on the driver side, one on the pass side.

I haven't done it yet, but my plan is to put a 2005 truck pump in a TJ tank, similar to how this guy did it:

5.3L LS engine swap fuel system solution

www.pirate4x4.com

A huge advantage is that if you ever decided that 19 gallons isn't enough, the big Genright tank is an easy swap.

I also like the fuel filler coming out at an angle, so it isn't in the cargo area.

Edit: Genright tank is $1800-$1900, but seems like the right path for a build of this caliber, it's just money.

26 gal: 26 Gal Gas Tank for Tracer Susp w/7" Stretch

31.5 gal: Jeep LJ Safari Gas Tank & Skid Plate (31.5 Gal)

Do you think a fabbed aluminum tank would be more reliable? I don't think so, at least from what I have seen online. I have never owned a fabbed tank, so I have no first hand experiance. What items does it simplify? Not arguing, just trying to see where you are coming from.it seems a bit ridiculous to reuse a stock fuel tank given the quality of the build. if it dimensionally checks all the boxes, id be building a fab'd replacement. simplifies a lot of items all in one shot.

vent size isnt a big deal unless you plan on racing and refueling in a timely matter is a big deal.

I like that idea. What would you do to seal the current vents? Some of that fuel tank repair epoxy?Nothing more annoying than sitting at the pump with the damn thing clicking every 5 sec because the vent is too small.

Not even talking about trying to fill it with a jerrycan and the tank doesn't accept more fuel and shoots it back at you.

I have no problems with the stock tank provided that it's protected properly.

You could use a 90 degree bulkhead fitting for lower profile and place it wherever you'd like.