desertPOS

Red Skull Member

- Joined

- Jul 2, 2020

- Member Number

- 2236

- Messages

- 331

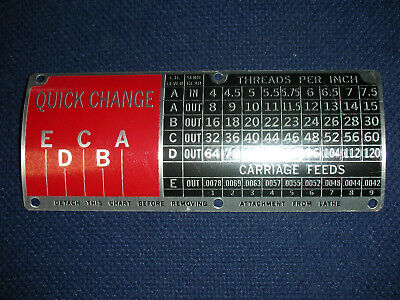

Kind of late and kind of a lame thread, but going to look at this lathe for sale tomorrow, and have no info other than the pic. Anyone know what it is or if it's worth picking up? Can't tell brand, though someone here might recognize it. I've never used a lathe and would like to learn - looks like it might be a good, small beginner setup, but don't know what it has for tooling, how easy it is to get tooling, etc.

Thanks in advance

Thanks in advance