You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ghetto fab / Hack fab

- Thread starter Blugreenformula

- Start date

dentedsub

Haberdasher

crispins

FJB

Welding to spring metal is no good now?

Geez we can't do anything anymore.

Rockwood

An Ape

I dunno. Needs moar triangulation...

Chang805

Member

If it had more shocks it wouldn’t have ended up there

Burns

Well-known member

I actually did a double take like "no....really? yes. Huh, good enough."

TRINDU

PBB Orphan

Spotted in a junkyard where it belongs.

Is it a drive through junkyard? Looks like half the yards in rural NE

thrillbilly85

Well-known member

- Joined

- Oct 5, 2023

- Member Number

- 6949

- Messages

- 138

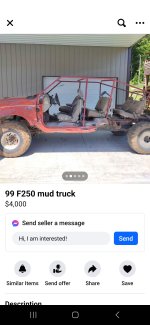

Here's a FB marketplace gem.

Hopefully he at least welded the square tubing blocks together.

Have a gander at the sweet Saginaw drop bracket and Bluetooth front driveshaft.

Hopefully he at least welded the square tubing blocks together.

Have a gander at the sweet Saginaw drop bracket and Bluetooth front driveshaft.

Burns

Well-known member

bet it corners well!Here's a FB marketplace gem.

Hopefully he at least welded the square tubing blocks together.

Have a gander at the sweet Saginaw drop bracket and Bluetooth front driveshaft.

Firstram

Well-known member

Glad to see it didn't have more power

BDK

Red Skull Member

Edit, I was really thinking this would end up in the DRT thread

Ah, but a man's reach should exceed his grasp, Or what's a heaven for

Mittnz

Red Skull Member

Here's a FB marketplace gem.

Hopefully he at least welded the square tubing blocks together.

Have a gander at the sweet Saginaw drop bracket and Bluetooth front driveshaft.

I was gonna say, I don't understand how people are doing front driveshaft angles like this but I can't lift my XJ more than 8", but, this one doesn't have one...

thrillbilly85

Well-known member

- Joined

- Oct 5, 2023

- Member Number

- 6949

- Messages

- 138

It's the Bluetooth driveshaft from AdamsI was gonna say, I don't understand how people are doing front driveshaft angles like this but I can't lift my XJ more than 8", but, this one doesn't have one...

SKULLYOTA

NOOB

- Joined

- Jun 30, 2023

- Member Number

- 6564

- Messages

- 374

Maybe he could put it on a mill to face both sides when he’s done welding

I’m intrigued. Seems like it would be a nightmare to keep everything lined up after welding.

It’s a bell housing

Coyote

Cup Holders & Rollbars

Wondering how they are holding the center line ?Maybe he could put it on a mill to face both sides when he’s done welding

SKULLYOTA

NOOB

- Joined

- Jun 30, 2023

- Member Number

- 6564

- Messages

- 374

Chunk of 2x4 and wood screwsWondering how they are holding the center line ?

I don't see a problem. It's covered in dirt but not bent or ripped off and must have worked, so is it really wrong?

Customer States: Front diff leaks every time he turns the steering wheel.I don't see a problem. It's covered in dirt but not bent or ripped off and must have worked, so is it really wrong?

What we think happened. It was like 6" taller and the ram was mounted on top of the axle. Someone lowered it and made that contraption and sold it.

Customer States: Front diff leaks every time he turns the steering wheel.

So he needs a new gasket?

filthy_midget

Well-known member

- Joined

- Apr 25, 2024

- Member Number

- 7748

- Messages

- 45

Chang805

Member

Didn’t get the greatest pictures, but trackbar and drag link mounted to opposite sides of the axle, and some really good looking welds. The double king steering stabilizers don’t look very sturdy as well

Didn’t get the greatest pictures

take away the crossed panhard/drag link that looks like a run of the mill ibb build. Slander flux core welds look like that