We found them completely ruined at year 4. No idea how long they were just beginning to fail before it but us in the ass. They cost WAY to much money per unit for only 3 years of service lifeMyself and others have also had issues with them deteriorating prematurely within a year, only running 94 pump gas. They were pretty hyped up in the beginning because they do work as advertised, I just dont think they hold up to long term abuse.

I am in the process of switching to the aeromotive phantom setup with the extra check valves and an extra pickup they call a jet siphon.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel pickups....what's the hotness today

- Thread starter pennsylvaniaboy

- Start date

Sean

Well-known member

- Joined

- Feb 9, 2023

- Member Number

- 6041

- Messages

- 1,413

Damn good to know. I was planning to go that route, but sounds like OEM is a better option.We found them completely ruined at year 4. No idea how long they were just beginning to fail before it but us in the ass. They cost WAY to much money per unit for only 3 years of service life

I was asking about a more positive connection but I guess a fuel safe barb could be used to connect to fuel line when a stock sending unit is not used.Tons of them use a little metal spring clip that digs into a plastic post.

Also, who cares. Fuel pumps survive even the most egregious crashes just fine.

My Walbros are 13 years old and holding strong

HYDRODYNAMIC

Rock Stacker

Downside to in tank pumps is there is no warning you are running low on fuel until the tank is dry. I can visually remember looking in the tank the first time it happened and seeing the dry bottom of the fuel cell.

Somewhere I wrote about how cool the oem in tank rollover valve is.

It’s pilot operated meaning the tank pressure can not lock up the valve. Once it goes sideways, it closes and even with pressure on it, it will reopen once right side up. Simple ball rollover valves can lock up under pressure and not unseat until pressure is removed.

From build thread:

The Goat Built fuel cell was designed to use the 2001-2003 truck pump. That year pump has a plastic top and QD fittings which will snap if you look at them the wrong way. They also require an external mounted filter/regulator, hoses, and fittings to plumb them all together.

Moving up to the 2005 year pump gets a metal top plate, fittings, and internal filter/regulator. This allows a single fuel line connection and a vent line with a high tech rollover valve. The internal tank pump also has a white plastic sump with a scavenging venturi nozzle at the bottom that uses the excess pumped fuel to pull more fuel into the sump. The sump also has flapper valves so fuel can come up from the bottom but not leak out. The long small QD is the regulated fuel out. The small and large QD on the round riser are the vent/rollover valve connection.

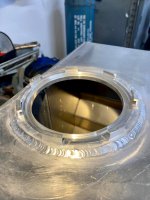

The new pump is larger in diameter with the added parts, so a new fuel cell plate and hold down ring is needed. A little trimming of the inside lip of the fuel cell might be needed depending on when and how it was made. If made to spec of the drawing it should just clear.

Somewhere I wrote about how cool the oem in tank rollover valve is.

It’s pilot operated meaning the tank pressure can not lock up the valve. Once it goes sideways, it closes and even with pressure on it, it will reopen once right side up. Simple ball rollover valves can lock up under pressure and not unseat until pressure is removed.

From build thread:

The Goat Built fuel cell was designed to use the 2001-2003 truck pump. That year pump has a plastic top and QD fittings which will snap if you look at them the wrong way. They also require an external mounted filter/regulator, hoses, and fittings to plumb them all together.

Moving up to the 2005 year pump gets a metal top plate, fittings, and internal filter/regulator. This allows a single fuel line connection and a vent line with a high tech rollover valve. The internal tank pump also has a white plastic sump with a scavenging venturi nozzle at the bottom that uses the excess pumped fuel to pull more fuel into the sump. The sump also has flapper valves so fuel can come up from the bottom but not leak out. The long small QD is the regulated fuel out. The small and large QD on the round riser are the vent/rollover valve connection.

The new pump is larger in diameter with the added parts, so a new fuel cell plate and hold down ring is needed. A little trimming of the inside lip of the fuel cell might be needed depending on when and how it was made. If made to spec of the drawing it should just clear.

Last edited:

HYDRODYNAMIC

Rock Stacker

More reposting:

The cad file for the plates are in the Irate download library.

The metal top plate and fittings along with the reduced plumbing and failure points were the big safety reasons for making the swap.

The old pump plate had insert nuts that got in the way of the inner plastic so that is the old trimming you see. The new plate and hold down ring use the outer mounting bolts since there is no room left. Making a new plate also make it easier to weld on the new filler elbow. I removed the small pressure sensor off the top of the pump, it looks like it monitors the tank air pressure probably for emissions. I used the provided rubber seal with a 1/4" bolt to seal it off.

Fuel pump and filler tube are in with a new fuel cell plate. The 2005 pumps use a 1/4" thick green o-ring between the pump and the plate so that is sandwiched in there to make the seal. The filler tube is 2" 3A sanitary elbows and barbs with a cam lock fitting nozzle and cap. I plan to get one of the autolock cam lock caps. This is the same one I used on the last buggy and the cams never unlocked or loosened but it would feel safer having the autolock.

The cad file for the plates are in the Irate download library.

The metal top plate and fittings along with the reduced plumbing and failure points were the big safety reasons for making the swap.

The old pump plate had insert nuts that got in the way of the inner plastic so that is the old trimming you see. The new plate and hold down ring use the outer mounting bolts since there is no room left. Making a new plate also make it easier to weld on the new filler elbow. I removed the small pressure sensor off the top of the pump, it looks like it monitors the tank air pressure probably for emissions. I used the provided rubber seal with a 1/4" bolt to seal it off.

Fuel pump and filler tube are in with a new fuel cell plate. The 2005 pumps use a 1/4" thick green o-ring between the pump and the plate so that is sandwiched in there to make the seal. The filler tube is 2" 3A sanitary elbows and barbs with a cam lock fitting nozzle and cap. I plan to get one of the autolock cam lock caps. This is the same one I used on the last buggy and the cams never unlocked or loosened but it would feel safer having the autolock.

Last edited:

gt1guy

Apparently a racist

I’m not all that impressed with Holley hydramat. We run it and works as advertised. But I have 4 of them that were brand new in 2019 that broke apart. The fabric got plasticized and brittle, then just broke apart like coral. They are in a fuel safe fuel cell stuffed with block foam and sit submerged in 110 octane.

Were all 4 of them used in fuel? I've got one from probably '19 that is still in the box. Makes me a little nervous now.

Yes, all 4 in the same cell the whole time. Race car with one HM in each corner plumbed in a common circuit.Were all 4 of them used in fuel? I've got one from probably '19 that is still in the box. Makes me a little nervous now.

DesertCJ

Name of Pheel...

More reposting:

The cad file for the plates are in the Irate download library.

The metal top plate and fittings along with the reduced plumbing and failure points were the big safety reasons for making the swap.

The old pump plate had insert nuts that got in the way of the inner plastic so that is the old trimming you see. The new plate and hold down ring use the outer mounting bolts since there is no room left. Making a new plate also make it easier to weld on the new filler elbow. I removed the small pressure sensor off the top of the pump, it looks like it monitors the tank air pressure probably for emissions. I used the provided rubber seal with a 1/4" bolt to seal it off.

Fuel pump and filler tube are in with a new fuel cell plate. The 2005 pumps use a 1/4" thick green o-ring between the pump and the plate so that is sandwiched in there to make the seal. The filler tube is 2" 3A sanitary elbows and barbs with a cam lock fitting nozzle and cap. I plan to get one of the autolock cam lock caps. This is the same one I used on the last buggy and the cams never unlocked or loosened but it would feel safer having the autolock.

What are you going to do when you roll your rig, bust the fill cap off and dump gas everywhere? Hope it doesn’t light off and BBQ you and/or your vehicle

Hopefully, that’s not the roof and I’m just not seeing the whole picture?

HYDRODYNAMIC

Rock Stacker

I never thought about that. I guess 24” from floor to roof was a bad idea, I was going for the ultra low rock bouncer look.What are you going to do when you roll your rig, bust the fill cap off and dump gas everywhere? Hope it doesn’t light off and BBQ you and/or your vehicle

Hopefully, that’s not the roof and I’m just not seeing the whole picture?

94toytruck

Eastcoast crawler

We found them completely ruined at year 4. No idea how long they were just beginning to fail before it but us in the ass. They cost WAY to much money per unit for only 3 years of service life

Guess I should take a look at mine then, it's about 4 years old now. I wanted to move my fuel fill neck anyways and it's time for filters anyway. Maybe I missed it but what's happening to them? Falling apart, getting brittle, hook up coming off the mat? Just want a idea what to look for.

🤣I never thought about that. I guess 24” from floor to roof was a bad idea, I was going for the ultra low rock bouncer look.

Guess I should take a look at mine then, it's about 4 years old now. I wanted to move my fuel fill neck anyways and it's time for filters anyway. Maybe I missed it but what's happening to them?

All of this

Falling apart, getting brittle, hook up coming off the mat? Just want an idea what to look for.

HYDRODYNAMIC

Rock Stacker

I remember how hyped up the hydramat was when it came out. All the cool kids had them.All of this

Google webpage loading ....

holly hydra....

Suggsted searches:

holly hydramat

holly hydramat problems

holly hydramat alternatives

holly hydramat walbro 450

Doesnt look like the internet worked out too well for them.

I’m still running it because it actually does the job. But for the dollars I’m bitter about having to replace them every few years. We have 4 smaller ones in one car and one big one in the other.I remember how hyped up the hydramat was when it came out. All the cool kids had them.

Google webpage loading ....

holly hydra....

Suggsted searches:

holly hydramat

holly hydramat problems

holly hydramat alternatives

holly hydramat walbro 450

Doesnt look like the internet worked out too well for them.

94toytruck

Eastcoast crawler

First thing that I ran into when I googled Hydramat issues was a post on RD about them. Then I saw no reason for a prefilter with it, then I realized I have a 7 micron between my pump and hydra mat. At first I thought man maybe I screwed up but now I'm thinking maybe that huge 7micron log filter isn't a bad idea if they are falling apart after a few years.

I’d still recommend a filter before the pump. I can’t find the bad HM’s at the moment but this was what took out the 4500 car at hammers this year. That’s the low pressure fuel pump

arse_sidewards

Red Skull Member

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,555

People have been fighting foam and plastics for 20+yr. I can't believe that nobody has figured out how to make metal baffles work yet.

pennsylvaniaboy

make fullsizes great again

- Joined

- Jun 27, 2020

- Member Number

- 2192

- Messages

- 1,061

So adding some more things to the discussion...

these have all three lines plumbed in with a fill, but does have exposed wire terminals

18-0941-In-Tank Fuel Pump Module - Single 255LPH Pump

Then this has a sump like feature....

Tanks Inc In Tank Fuel Injection Pump Module Walbro 255lph 630HP EFI Kit | eBay

then FI tech

FiTech Fuel Injection 50015 FiTech Go Fuel In-Tank Pump Modules | Summit Racing

these have all three lines plumbed in with a fill, but does have exposed wire terminals

18-0941-In-Tank Fuel Pump Module - Single 255LPH Pump

Then this has a sump like feature....

Tanks Inc In Tank Fuel Injection Pump Module Walbro 255lph 630HP EFI Kit | eBay

then FI tech

FiTech Fuel Injection 50015 FiTech Go Fuel In-Tank Pump Modules | Summit Racing

pennsylvaniaboy

make fullsizes great again

- Joined

- Jun 27, 2020

- Member Number

- 2192

- Messages

- 1,061

HYDRODYNAMIC What's the durability rate of those pumps? im curious because it's hard to pack a spare. I know for my external pumps, a spare is the size of a pop can and party on.

Grendel

Iron Sharpens Iron

- Joined

- May 19, 2020

- Member Number

- 297

- Messages

- 3,521

I am in the complete factory camp, with parts available anywhere. USCar standard.

The 2017 Corvette ZL1 pump is 2 pumps in one and PWM - was 279.00 at Rock Auto

Holley didn't make the smaller size weld on ring when we were doing this before, so we changed the top hat to a large one and set depth.

www.holley.com

www.holley.com

Now they have both sizes, so run which ever you want.

Vaporworx also has corner pick ups, that add onto the pumps inlet just fine.

www.vaporworx.com

www.vaporworx.com

I wish this was out when I made the other tank:

www.vaporworx.com

www.vaporworx.com

The 2017 Corvette ZL1 pump is 2 pumps in one and PWM - was 279.00 at Rock Auto

2017 CHEVROLET CORVETTE 6.2L V8 Supercharged Fuel Pump & Housing Assembly | RockAuto

RockAuto ships auto parts and body parts from over 300 manufacturers to customers' doors worldwide, all at warehouse prices. Easy to use parts catalog.

www.rockauto.com

Holley didn't make the smaller size weld on ring when we were doing this before, so we changed the top hat to a large one and set depth.

Mounting Rings for Fuel Pump Modules

Now they have both sizes, so run which ever you want.

Vaporworx also has corner pick ups, that add onto the pumps inlet just fine.

Corner Pickup Kit - VaporWorx

Add corner pickups to your Gen5 Camaro, CTS-V2, and C7 Corvette fuel modules for the ultimate in low fuel level performance.

I wish this was out when I made the other tank:

Fuel Pump Module Mounting Ring - Small Diameter - VaporWorx

Stainless steel weld-in fuel module mounting ring. Build your own mounting tray, weld in the ring, and insert the appropriate OEM fuel module!

Attachments

pennsylvaniaboy

make fullsizes great again

- Joined

- Jun 27, 2020

- Member Number

- 2192

- Messages

- 1,061

Could you used the pump that HYDRODYNAMIC listed that is metal? With the corner pickup and then use a custom mount ring? On the plastic?

My other thought is the Holley pump/filler system with the corner pickup

My other thought is the Holley pump/filler system with the corner pickup

HYDRODYNAMIC

Rock Stacker

In stock form, it’s pretty good considering you have to drop the tank or take off the bed to change it. Running dirty gas can clog the filter prematurely and running dry all the time will shorten life. I see no reason to run special pickups when the stock one can empty a tank near dry.HYDRODYNAMIC What's the durability rate of those pumps? im curious because it's hard to pack a spare. I know for my external pumps, a spare is the size of a pop can and party on.

HYDRODYNAMIC

Rock Stacker

I thought about baffling with 2” or 3” polyethylene tube cut up into 2”or 3” short pieces. Downside is the stock fuel sender arm will get caught up in the baffling. So choose fuel gauge vs baffling.

AgitatedPancake

Frobot

Interesting on the ZL1 setup, and it actually has two independent pumps within the canister? The pickup being a fitting is interesting too, not sure if I'd prefer that over a sock like the trucks have.

Hydro that 05+ truck setup is sweet too. Could you possibly explain the operation of the fancy rollover valve and the venturi return system? On the venturi side, I see the two red rubber flap/check valves versus the standard one, so the second is dedicated to that purpose? The the fuel moves from the pump through the filter/regulator within that black plastic assembly, then down those white tubes to the bottom of the sump, and is directed in a way to pull a check valve open via venturi?

Hydro that 05+ truck setup is sweet too. Could you possibly explain the operation of the fancy rollover valve and the venturi return system? On the venturi side, I see the two red rubber flap/check valves versus the standard one, so the second is dedicated to that purpose? The the fuel moves from the pump through the filter/regulator within that black plastic assembly, then down those white tubes to the bottom of the sump, and is directed in a way to pull a check valve open via venturi?

Grendel

Iron Sharpens Iron

- Joined

- May 19, 2020

- Member Number

- 297

- Messages

- 3,521

yes, confirmed that it's 2 pumps in the cannister.Interesting on the ZL1 setup, and it actually has two independent pumps within the canister? The pickup being a fitting is interesting too, not sure if I'd prefer that over a sock like the trucks have.

Hydro that 05+ truck setup is sweet too. Could you possibly explain the operation of the fancy rollover valve and the venturi return system? On the venturi side, I see the two red rubber flap/check valves versus the standard one, so the second is dedicated to that purpose? The the fuel moves from the pump through the filter/regulator within that black plastic assembly, then down those white tubes to the bottom of the sump, and is directed in a way to pull a check valve open via venturi?

I did a look up a while ago.

You can put a sock on it. It's the normal push lock fitting

pennsylvaniaboy

make fullsizes great again

- Joined

- Jun 27, 2020

- Member Number

- 2192

- Messages

- 1,061

OK so I have no room to fit a goatbilt style flange. So either a external pump or a holley seems like the win... with external return regulator.

Holley 12-144 Holley Fuel Cell EFI Pump Module Assembly

Holley Sniper EFI 19-380 Sniper Fuel Cell EFI Pump Module Assembly-Return Style

Speedway Deluxe AN6 GM LS Swap Fuel Filter/Regulator, 58 PSI

What I cant figure out is why the holley 340 setup is cheaper than the holley 255 setup? The look basically the same and the 340 technically flows more, and comes with fittings at the top.

Or go external setup, but till you buy the fitting and filler its a close tie.

Holley 12-144 Holley Fuel Cell EFI Pump Module Assembly

Holley Sniper EFI 19-380 Sniper Fuel Cell EFI Pump Module Assembly-Return Style

Speedway Deluxe AN6 GM LS Swap Fuel Filter/Regulator, 58 PSI

What I cant figure out is why the holley 340 setup is cheaper than the holley 255 setup? The look basically the same and the 340 technically flows more, and comes with fittings at the top.

Or go external setup, but till you buy the fitting and filler its a close tie.

cdemart2

Well-known member

- Joined

- Nov 4, 2021

- Member Number

- 4528

- Messages

- 130

I have dual bosch 044 pumps in-tank with socks on them. probably not the hot setup for hardcore rock crawling but that's not what I built the car for. thirty two gallons makes it work good enuf for me I guess.

if fuel starvation was an issue for me, I'd be looking at a trap door surge tank instead of a hydramat. fuel safe makes a few and ATL makes them with or without single or dual 044 pumps mounted to them. not cheap obviously but IMO the best solution.

if fuel starvation was an issue for me, I'd be looking at a trap door surge tank instead of a hydramat. fuel safe makes a few and ATL makes them with or without single or dual 044 pumps mounted to them. not cheap obviously but IMO the best solution.

Attachments

94toytruck

Eastcoast crawler

What a convenient reminder to change my fuel filter tomorrow and look for hydramat pieces.

JBT

Member

- Joined

- Dec 24, 2020

- Member Number

- 3172

- Messages

- 23

Why not go for 4 lift pumps feeding a surge tank with high pressure pump in it? That's what Porsche is using in their race cars.

I spoke to deatschwerks on SEMA show and they said that their lift pumps can run dry for a couple of minutes without any problem.

Deatschwerks Lift pump.

I spoke to deatschwerks on SEMA show and they said that their lift pumps can run dry for a couple of minutes without any problem.

Deatschwerks Lift pump.

HYDRODYNAMIC

Rock Stacker

Been thinking about whether to use the tank level sender or not and while looking at my filler.

I started thinking how am I going to not over fill it.

Having no air space in the tank and only a little air in the 2" fill line means the vent valve is under fuel and probably leaking out fuel rather than fumes and the pump plate is holding fuel from leaking out, but I guess this is the norm since fuel is sloshing around all the time.

I could add a couple inches of tube to the inside of the fill plate which would create an air gap above it to help keep the vent dry on even ground. This seems like a good idea but robs some fuel volume?

One option is to add a bulkhead down low and add a clear teflon sight tube up to the top. This make it easy to fill and see level but makes a hole in the goatbuilt tank???

A number of poly tank manufactures have bulkheads at the bottom.

A sending unit would be helpful but hard to use for filling, also can use baffles or foam with a sending arm.

Using a vent line with a float check for full tank feedback and a dry break with pressure seal is cool but then I have to have dedicated fill tanks and $$$ dry break hardware. I want to be able to fill up at the gas station nozzle or from an old 2 liter mountain dew bottle in the middle of no where.

Am I being paranoid to drill a hole in the side of my cell?

Not that I am racing but would a sight tube pass tech?

I started thinking how am I going to not over fill it.

Having no air space in the tank and only a little air in the 2" fill line means the vent valve is under fuel and probably leaking out fuel rather than fumes and the pump plate is holding fuel from leaking out, but I guess this is the norm since fuel is sloshing around all the time.

I could add a couple inches of tube to the inside of the fill plate which would create an air gap above it to help keep the vent dry on even ground. This seems like a good idea but robs some fuel volume?

One option is to add a bulkhead down low and add a clear teflon sight tube up to the top. This make it easy to fill and see level but makes a hole in the goatbuilt tank???

A number of poly tank manufactures have bulkheads at the bottom.

A sending unit would be helpful but hard to use for filling, also can use baffles or foam with a sending arm.

Using a vent line with a float check for full tank feedback and a dry break with pressure seal is cool but then I have to have dedicated fill tanks and $$$ dry break hardware. I want to be able to fill up at the gas station nozzle or from an old 2 liter mountain dew bottle in the middle of no where.

Am I being paranoid to drill a hole in the side of my cell?

Not that I am racing but would a sight tube pass tech?

Last edited: