i'm curious why you are still not printing these upside down, seems like it would take out a huge amount of the support and stress and related issues.

There's a lot of debate on that. Probably 50/50 on rails up vs. down. I'm still having support quality issues and the last one I tried rails down had way too much ugliness in the cavities and it's harder to get out. I'd rather have a little shitty surface on the underside of the trigger guard and front lower side of the frame and still be functional vs. a shitshow inside. Of course the one i tried upside down was with PETG so i should probably give it another shot with PLA+.

The one I started last night failed about halfway though. I had half a frame with a pile of spaghetti on top. I'm leaning toward an extruder problem now.

any thoughts on using PETG instead of PLA or PLA+ ?

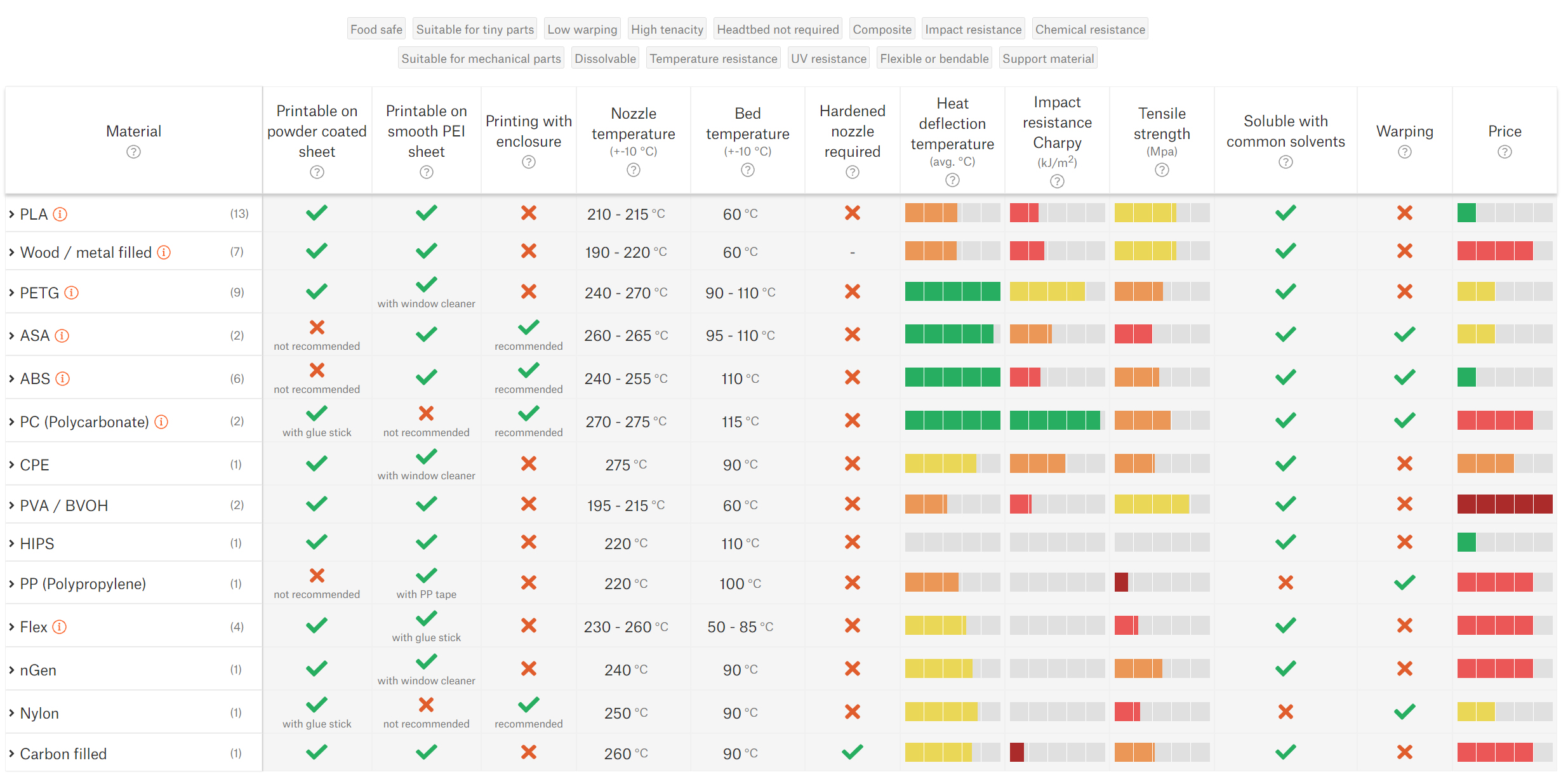

i should probably start another thread, but it looks like PETG has similar heat requirements, but with higher impact resistance, hardness, than PLA so it might hold up better to the abuse of the slide

Prusa Material Table | Prusa Knowledge Base

Our filament guide table includes all sorts of supported…help.prusa3d.com

PLA Vs PETG: Differences And Which Is Stronger? - MakerShop

PLA and PETG are two of the most popular 3D printing filaments around: so what are the differences between PLA and PETG, and which one should you be using formakershop.co

All of t he first ones I posted before the last were PETG. The gray one is the first I tried with PLA+.

I've printed almost exclusively with PETG on this printer. At the beginning because I was printing gears for my lathe (the main reason I bought it in the first place) and I just stuck with the because I use it so sporadically I'd always end up with moisture problems with PLA. PETG can sit for months and go right back to printing.

I picked up a drier box for the PLA last week so I should be able to keep it "fresh" a little better now.

I had to pull the pins and fully disassemble to get it the slide off.

I had to pull the pins and fully disassemble to get it the slide off. for perseverance!

for perseverance!