bgaidan

Red Skull Member

- Joined

- Jul 18, 2020

- Member Number

- 2322

- Messages

- 2,943

Figured I'd post some pics here as I play around. I've been seeing pics of these pop up on various sites and have been meaning to print one just to see how it goes. Finally got around to downloading one last night. 8 hours later I had what I guess is legally considered a firearm.

Figured I'd post some pics here as I play around. I've been seeing pics of these pop up on various sites and have been meaning to print one just to see how it goes. Finally got around to downloading one last night. 8 hours later I had what I guess is legally considered a firearm. I went with the subcompact glock because I already have a 26 and I can test fit the parts from it here. Eventually if I order new parts, I'll go with a bigger frame model.

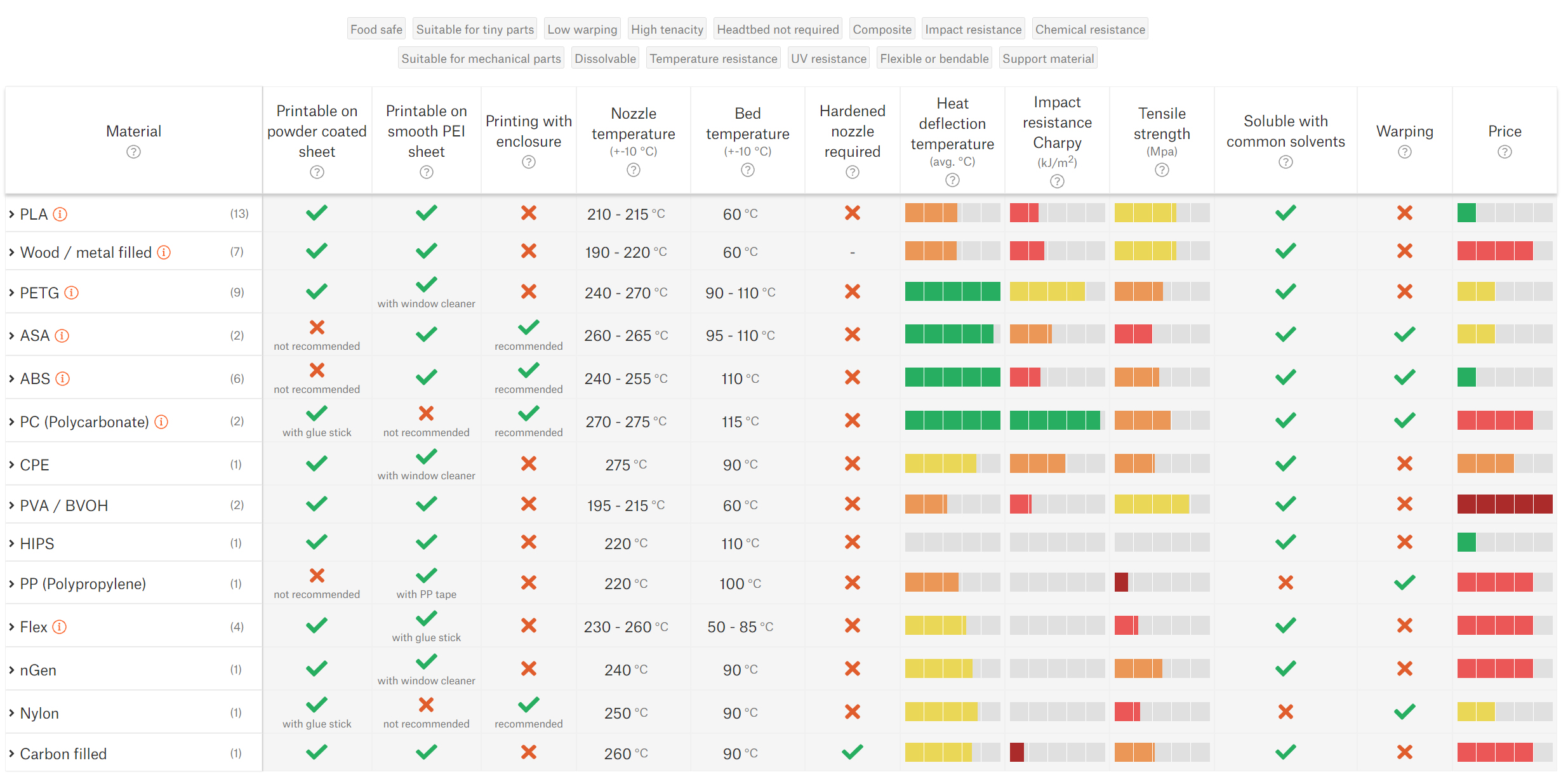

I forgot that I hadn't used my printer since I wiped my old HD and updated to Win10 so I had lost my old profiles in my slicer. I pulled in a recommended stock profile and made some very minor tweaks and sent it. Some things were off....like the support method I used was a little too liberal and I ended up with a lot of excess support material. I did this in PETG because that's what seems to print best on my little machine. PETG doesn't always do nice clean support breaks so there's quite a bit more cleanup than I would like.

This is what it looked like when it finished printing:

After some quick support pealing with a pair of pliers, I found a frame under all that shit:

So lots of support that didn't come off as easy as it should, but overall I'm not unhappy with the result for a first print with no tuning.

I whittled away at the support a little more when I got to work this morning and it's looking much better. The file I downloaded has several options for grip textures.. This one was a honeycomb type texture. I also screwed up here because I used a file that had "microtexture" which my printer won't do with PETG so that probably contributed to the shitty surface finish.

Of course I also fucked up and forgot to change the infill %. They recommend doing this at 100% and my slicer defaulted to 20%. There only a couple places thick enough for infill, mostly around the top of the grip, but I can feel that it's a bit weak there. So this will be a practice piece. I threw a new file to the printer this morning with the correct parameters changed and 100% infill and a different style of support so I should have a better example to play with when I get home tonight, but I'm confident this one could be made to work if I wanted to.

If that one works, I'll tear down my 26 and see what fits. There's a chance that I'll see some shrinkage in the PETG. I do have it tuned for shrinkage, but I don't usually print stuff this big so I may have to dial it in some more if parts aren't fitting right.

I honestly can't remember what's removable on the factory glock, like rails, so I don't know if I'll be able to 100% assemble it to fire without ordering some parts.

So for a couple bucks worth of filament and about 8 hours, I have what they feds would consider a firearm. You can buy a complete upper and lower kit for it for about $380, but if you're thrifty and shop around for deals, I'd bet you can get that under $300.