CDA 455 II

ANFAQUE2

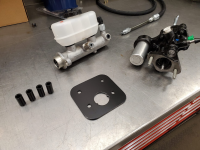

I'm looking to upgrade my '94 Bronco to a '94 F-350 HB set up.

So far it appears mod'ing the pushrod/brake pedal length will be my biggest hurdle.

What simple way(s) can this nOOB accomplish this mod?

My thought for a simple mod is to weld a bracket on the pedal for the pin where the pushrod hole will be.

Does that sound doable?

FYI:

Rear axle: '87 10.25 dually w/drums

Front axle: stock TTB

So far it appears mod'ing the pushrod/brake pedal length will be my biggest hurdle.

What simple way(s) can this nOOB accomplish this mod?

My thought for a simple mod is to weld a bracket on the pedal for the pin where the pushrod hole will be.

Does that sound doable?

FYI:

Rear axle: '87 10.25 dually w/drums

Front axle: stock TTB