Not sure because i have always had the gt3 lca that can be shimmed. I think 1.5-2* in front and similar in the back. U may need high camber upper mounts in front to get more. U can get affordable adjustable dog bone uppers in the rear that can get u more. I run 4* front and 3.1* rear

Caster in front is non-adjustable unless u get pucks for the lca but i should be in range or close enough.

No eccentrics in the front so nothing to lock out and the rear has lca and toe bar eccentric but they only offer a lock out kit for the toe bar and u would have to get adjustables. U may need the adjustable toe bars anyways depending on ride height.

The front sway links bolt to the upright so they should be fine and the ohlins should come with a bolt in bracket in back so u should be good there too. This all depends on ride height.

Easiest thing u can do is make some cheap hub stands to make alignments easier. I also have a set of string fixtrures that hook onto the car.

Tweaked my knee snowboarding and pretending I'm still 20. Been out of the shop for about a week but hobbling around again.

Got it, thank you. I remember going through your build thread and the GT3 conversion was very fun and informative, I learned quite a bit. I was researching the 996 suspension upgrades since I've been out of the shop and compared the gt3 lower arms (adjustable) to buying adjustable upper arms (dog bones). For my purposes, I think the upper arms are a better way to go. I need to get under the car again and make a plan based on worn components and fitment and track goals. After talking with quite a few fellow 996 track enthusiasts and P car shops, the upper arms and Ohlins are the best bang for my buck right now.

I also looked at designing my own alignment hub stands and it's not as cheap as I'd like, but stll considerable cost savings. It's about $650 for me to make a set, given I don't have my plasma CNC anymore and I'd be ordering hardware from McMaster. This DIY kit, however, is actually a good design and a pretty good deal from what I can see for about $850 all in:

Desctiption:This is our weld-it-yourself wheel hub stands, an elegant solution for DIY alignment at home. We designed these as a weld-it-yourself kit, and the kit will be shipped unassembled. We designed these to work with Hudson BT-1-1/2 ball transfer bearings for a near frictionless interface...

turtlelaboratories.com

I'll probably wait to make these until I'm tired of paying for alignments at the local shops. I'm going to attempt to negotiate an annual fee since I'll want to change alignment a few times a year based on street or track use. Unless I get lazy....which is very possible....and I decide to use a street setup on the track and avoid alignment changes altogether. Hah!

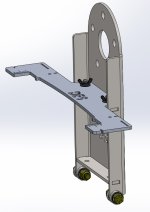

Anyway here's my design, a mix of others I saw. I'd probably make the bolt pattern plate a separate piece so I can swap it out for other vehicles easily. The bearings have a static load rating of 530 lbs each, there's 4 on each stand, so max load is 2120 lbs for each stand, 8480 lbs for total vehicle weight. Rolling load is quite a bit higher. I'll probably run these through FEA to see if they could actually withstand those loads, but for my little 3000 lb Porsche 911, these should work fine. Stand itself is 1/4" steel, laser cut and CNC bent, and the alignment plate itself is 3/16" aluminum for ease of use and storage. Alignment plate also has slots for tape measure, string cutouts, degree markings laser etched, and could be anodized for some bling.

If anyone is interested in a pair or set, let me know and I'd do a group buy and maybe we can bring down the cost. No profits, just straight cost for everything.

I've also been pondering how I can add a X or H pipe to the exhaust. I think an X pipe is out of the question due to space constraints. I'm sure I could do it, and even started it in CAD again, but an H pipe is much easier. I was considering a pipe across the back, with 2 more v band clamps. This should be pretty quick, and if I screw it up, it should be a quick fix. What's the thoughts on this? I've researched quite a bit, and looked through as many other 180 header builds as I could find and most experiment with X pipes and keep them, some don't.

Curious as to everyone's thoughts and experiences on H and X pipes. H pipes typically offer more lower end grunt noises and X pipes offer more high end zings. Since my setup is already somewhat high pitched and sounds like two 4 cylinders, I think an H pipe would give it a more robust tone with a more exotic sound that I've been chasing.

Current sound:

More expected sound with X pipe

H pipe vs X pipe video that really highlights the differences

Sounds like your niece should invite us out, Greg! lol

Sounds like your niece should invite us out, Greg! lol

no worries! A resin printer (SLA) or powder sinter (SLS) could handle most any shapes but those are $$$ especially at this size. FDM (filament) is cheapest for a part this size.

no worries! A resin printer (SLA) or powder sinter (SLS) could handle most any shapes but those are $$$ especially at this size. FDM (filament) is cheapest for a part this size.