YotaAtieToo

Thick skull

What I read said 36 spline? Which is basically no tcase I'm aware of

Internet consensus says 36 spline... my memory fails me. It was about 4 years ago when i did all that digging to find i couldn't use it... so that means the Ford np input is no good.What I read said 36 spline? Which is basically no tcase I'm aware of

Internet consensus says 36 spline... my memory fails me. It was about 4 years ago when i did all that digging to find i couldn't use it... so that means the Ford np input is no good.

Honestly, i wanted to use the 90, it's a beast, always been a work truck, it has towed 10-12k for at least 100k of its 260k life i would run that trans without rebuilding. It never slipped once, and the fluid was as beautiful as the day it was installed... but the input for the underdrive was becoming more than i wanted to deal with. We even looked into swapping the output from the 80 to the 90. That was a dead end as well.So in short, a 6l80e is superior for offroad rigs? The 90e is a little beefier, maybe better for towing only?

), and in low range with 6 gears it should haul ass pretty good when required. They're becoming plentiful, and you can do a bench rebuild for less than 500 if you so desire. Stock they're good for at least 500 hp, and with a little cash you can get that number up to 750 hp no problem. I've got around 500 into mine, includes purchase and rebuild by my good friend.

), and in low range with 6 gears it should haul ass pretty good when required. They're becoming plentiful, and you can do a bench rebuild for less than 500 if you so desire. Stock they're good for at least 500 hp, and with a little cash you can get that number up to 750 hp no problem. I've got around 500 into mine, includes purchase and rebuild by my good friend.

I'm following along. I have a standalone 4.3 LV3 and 6L80E combo, and also need to understand the 4wd stuff.My big concern with all of this is that I'm trying to get my 2wd to think it's a 4wd. That's not a big deal until i slip it into low and want it to shift... will i need to get a 4wd harness to put a tcm for getting it to shift in low? I honestly haven't talked to a single programmer about my build yet, but i have to get that going so I'm not sitting here with a truck that can't do shit until the comp is figured...

I hope you're rightFrom what I've read, the speed sensors are all in the trans, so it should shift likes its supposed to.

I put a 6.2/6l80e/atlas in my father in laws jeep, but haven't ran it yet. That was what I had found.I hope you're right

I need to get back into research mode and get it figured out, that's for sure.

When i was reading up on doing this, everything pointed to me only needing the ecm reprogrammed, because it is 2wd. Now that we're discussing, all the details are w coming back to me.I put a 6.2/6l80e/atlas in my father in laws jeep, but haven't ran it yet. That was what I had found.

My buddy has the same engine and trans in his JK, both from a 2010 escalade which don't even have low range. His is all stock tuned for smog, so I assume they didn't do anything with the trans either.

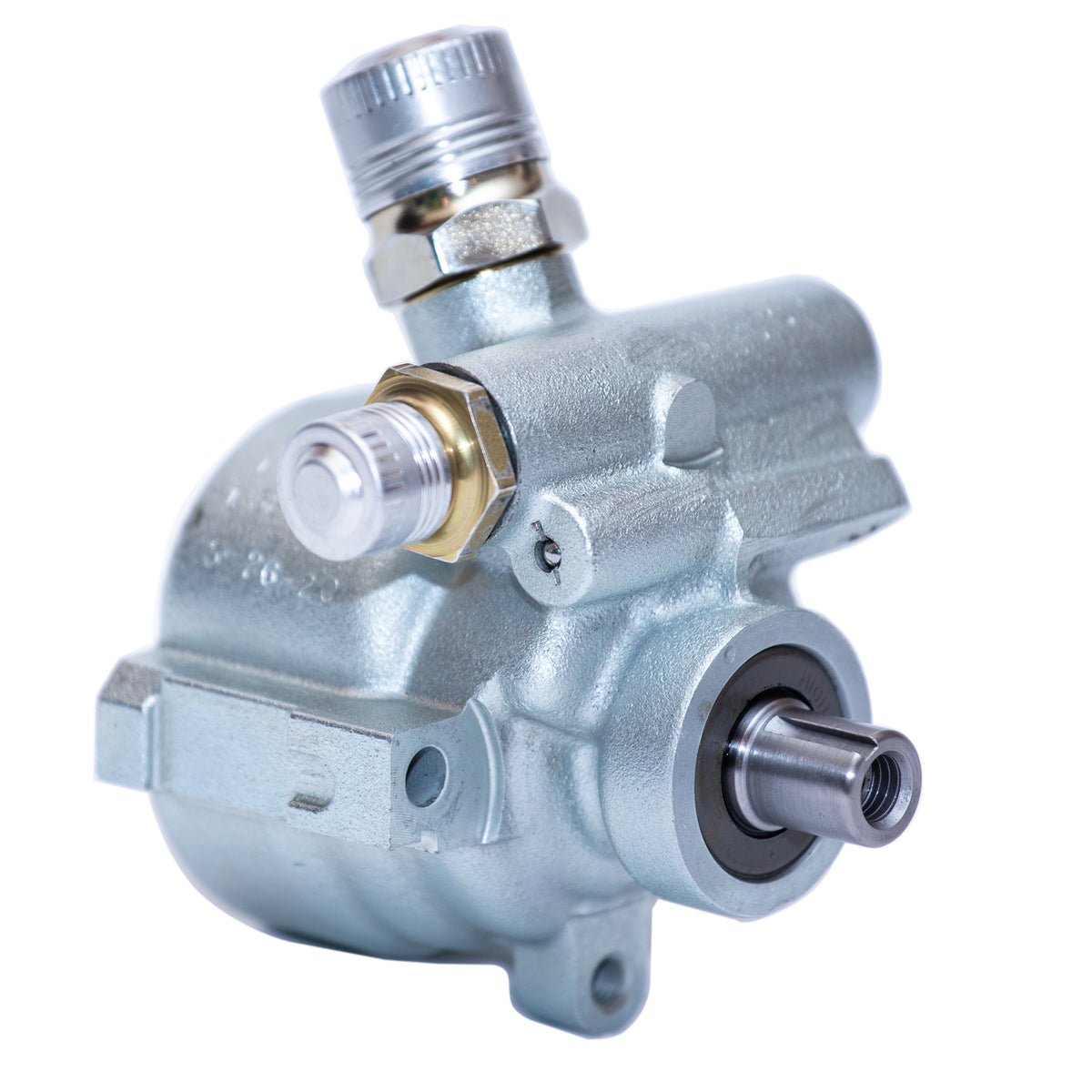

Desert truck guys will often put a remote hydroboost, sideways, between the rad and damper pulley.Of course it looks good all cleaned up... but the shock and master cylinder want to occupy the same space. I know the mc was there first, but the shock has no real choice, unless i want to raise ride height about 4"... ummmm NO. I'm just going to pull the mc, get the shock mounted and go from there. I've been looking at hot rod power brake setups. They generally turn their mc/ booster 90°. Usually under the dash, but that gives me hope. I'm going to try to fab a bracket to get my Mc turned about 30° toward the inside of the engine bay.

Master cylinder on the "firewall" and slave cylinder pushing on the remote master?Desert truck guys will often put a remote hydroboost, sideways, between the rad and damper pulley.

Frees up a lot of room for shocks, right in the area you're talking about.

I read about that. Hotrod guys will do it as well. From what i read it takes a secondary hydraulic system to accomplish with a specific mc. I want to use what i have instead of buying more. I was also thinking of remote mounting my current mc and using an aircraft cable to pull a turn buckle to push the rod into the booster will be feasible? I will research the options a bunch more before i do anything permanent. First things first, the shocks need to be mounted.Desert truck guys will often put a remote hydroboost, sideways, between the rad and damper pulley.

Frees up a lot of room for shocks, right in the area you're talking about.

Yes, exactly. A lot of medium duty trucks from back then did it as well. There are options for me, i just don't think they're cheap.Master cylinder on the "firewall" and slave cylinder pushing on the remote master?

Some 50s Chevy trucks did basically the same thing to remote mount under the cab to fit the vacuum booster.

Remote mount only adds like $100ish and an hour or two of looking up parts and figuring out which master and random clutch slave and small car master will work.Yes, exactly. A lot of medium duty trucks from back then did it as well. There are options for me, i just don't think they're cheap.

100 for the slave, but to you still need to purchase the booster and mc made to be worked remotely, plus brackets and the rest of the parts necessaryRemote mount only adds like $100ish and an hour or two of looking up parts and figuring out which master and random clutch slave and small car master will work.

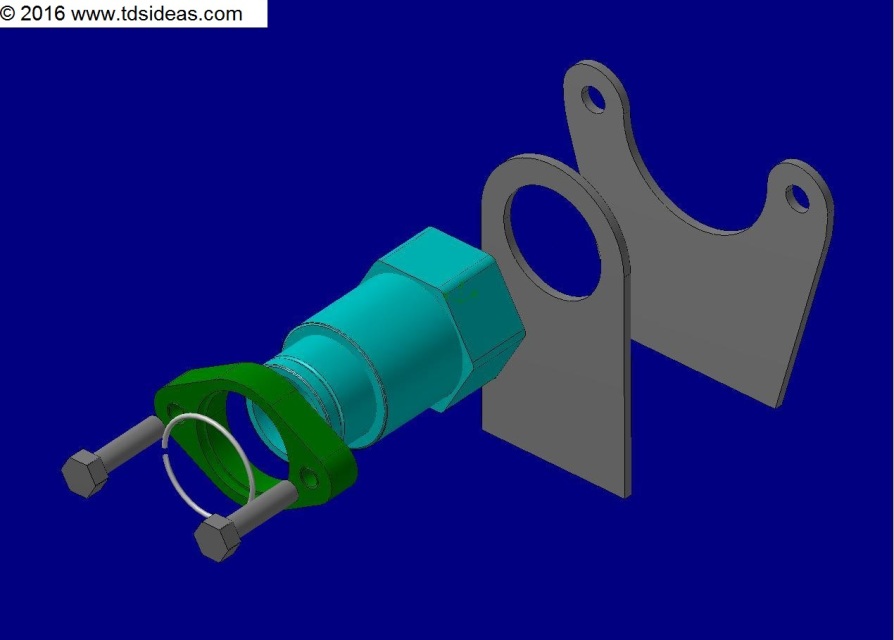

No you don't. Buy a slave that uses a pushrod. Whip up apropriate brackets, do whatever fiddling is required to make the slave pushrod play nice with the booster. Done. The booster doesn't care whether the pushrod is being pushed by the brake pedal or another cylinder.100 for the slave, but to you still need to purchase the booster and mc made to be worked remotely

No you don't. Buy a slave that uses a pushrod. Whip up apropriate brackets, do whatever fiddling is required to make the slave pushrod play nice with the booster. Done. The booster doesn't care whether the pushrod is being pushed by the brake pedal or another cylinder.

Some old gm bread vans have the master cylinder turned sideways and a cantilever to push on the master

I would think it would be easy to fab up a bracket that rotates the whole thing 90 degrees and then make a simple lever like mentioned above. the rest is just plumbing. I sure am glad I decided on a 12" shock. it gets really tight on that side. I ended up mounting the lower side of the shock down off the tube behind the axle tied into the lower control arm bracket.

Lol, I'm not sure...i figured out i couldn't make my deadline, plans changed, money, but you know, mostly excuseshow the F is this not done yet? Pretty sure ive built wheeled and scrapped, and started a new rig in the time its taken you to get to this point

but its looking good and nice to see some updates

Got it figured out now. Going to go hydraulic setup to completely relocate the booster and master.Look at EB bronco brake setups, might be able to use the offset linkage and mount from there?