You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need dimensions! JD2 Model 32 Bender!

- Thread starter Toxocara

- Start date

Why not go with the Got Trikes plans and build one of those for cheap money if you are on a tight budget? The excuse about dies not being available in the future is invalid. You can still buy them now and how many different size dies do you think you will need in your lifetime? I built this one over 20yrs ago using Got Trikes plans, some pin stock from McMaster and drops from the local steel place for under $200. I just used it a few nights ago to build a seat bracket with a die I bought 15yrs ago.....

CarterKraft

Red Skull Member

And absolutely don't buy a die that your buddy has... We all have the same shit, it would be really nice to borrow the die you need for one off projects instead of every due costing you $300+Why not go with the Got Trikes plans and build one of those for cheap money if you are on a tight budget? The excuse about dies not being available in the future is invalid. You can still buy them now and how many different size dies do you think you will need in your lifetime? I built this one over 20yrs ago using Got Trikes plans, some pin stock from McMaster and drops from the local steel place for under $200. I just used it a few nights ago to build a seat bracket with a die I bought 15yrs ago.....

I bet OP can't build one for this price...

SomeGuyFromOlympia

Well-known member

- Joined

- May 31, 2020

- Member Number

- 1706

- Messages

- 905

I will second thisAnd absolutely don't buy a die that your buddy has... We all have the same shit, it would be really nice to borrow the die you need for one off projects instead of every due costing you $300+

I have a close fab friend, we will not buy dies without checking with the other guy first. Same deal, no point if both of you having the same stuff

arse_sidewards

Contrary to everything

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,005

I'd like to see someone come out with a set of plans for laser cut bolt together dies and post them on the internet.

At the very least that should drive the cost down through competition.

At the very least that should drive the cost down through competition.

I'd like to see someone come out with a set of plans for laser cut bolt together dies and post them on the internet.

At the very least that should drive the cost down through competition.

Have you bought any tube lately? The bender and dies are the cheap part these days.

CarterKraft

Red Skull Member

HREW for the win!Have you bought any tube lately? The bender and dies are the cheap part these days.

CarterKraft

Red Skull Member

Curbs don't care

arse_sidewards

Contrary to everything

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,005

ThisHREW for the win!

I'm not building a fucking race car. HREW and pipe are fine for sliders and shit.

Brad

Jackass

I’ve seen many cages made out of HREW do just fine without any failures.

I’ve seen many cages made out of HREW do just fine without any failures.

I've seen sch 40 cages take abuse too. Doesn't mean I'm doing it.....

I'm not building a fucking race car.

We are well aware of that already

Brad

Jackass

Paging SWAG…I'd like to see someone come out with a set of plans for laser cut bolt together dies and post them on the internet.

At the very least that should drive the cost down through competition.

subybaja

E. Spengler

I'd like to see someone come out with a set of plans for laser cut bolt together dies and post them on the internet.

At the very least that should drive the cost down through competition.

Steel/aluminum oreo cookie.

JD2 Tube bender DIY – Mungruls Blog

mungrul.ie

mungrul.ie

Double Flute Round Nose Bit

7/8" Radius

1-3/4" Cutting Diameter

1-1/4" Cut Length

3" Overall Length

1/2" Shank

CarterKraft

Red Skull Member

That's pretty awesome.Steel/aluminum oreo cookie.

JD2 Tube bender DIY – Mungruls Blog

mungrul.ie

Double Flute Round Nose Bit

7/8" Radius

1-3/4" Cutting Diameter

1-1/4" Cut Length

3" Overall Length

1/2" Shank

Pook

Red Skull Member

Would be real easy to do. If you used real thin gauge steel for the bulk of the middle section, you wouldn't even need to worry about all the small steps.I'd like to see someone come out with a set of plans for laser cut bolt together dies and post them on the internet.

At the very least that should drive the cost down through competition.

[memphis]

Web wheeler

- Joined

- Jun 6, 2020

- Member Number

- 1867

- Messages

- 710

Guys I started digging into this more as something was off with this ad. Can you use Model 32 dies in a Model 3?This is 3 hours away but I saved it several weeks ago… I thought it was an OK deal even without a die I require

On the Amazon link does that use JD dies?

This bender doesn't have the "spring back" arm on it... so there is no way it's a Model 32 correct?

The dies are stamped 32 but I'm not even sure if this unit has been used?

CarterKraft

Red Skull Member

You can use 32 dies in a 3 just have to sleeve the center pin hole.Guys I started digging into this more as something was off with this ad. Can you use Model 32 dies in a Model 3?

This bender doesn't have the "spring back" arm on it... so there is no way it's a Model 32 correct?

The dies are stamped 32 but I'm not even sure if this unit has been used?

Correct on the springback pin missing on the 3.

[memphis]

Web wheeler

- Joined

- Jun 6, 2020

- Member Number

- 1867

- Messages

- 710

Used value just dropped significantly for me. Seller is asking $1200 ($830 freedom bucks) so that doesn’t really seem worth it for dies I’m not going to use (1” and 1.125”) Seller hasn’t responded to any questions so it might not even be availableYou can use 32 dies in a 3 just have to sleeve the center pin hole.

Correct on the springback pin missing on the 3.

Landslide

Red Skull Member

- Joined

- May 20, 2020

- Member Number

- 422

- Messages

- 1,483

That may or may not work. Benders I had in the past like the one OP is talking about, use half dimensions not whole. What I mean is, their 1 3/4” tubing die has a radius of say 5.5”. I sold all that stuff for the JMR for two reasons. One, their arms are strong enough to bend serious thick wall DOM tubing. Secondly, their dies are whole number radius measurements i.e. 1 3/4” tubing die with a 5” radius.And absolutely don't buy a die that your buddy has... We all have the same shit, it would be really nice to borrow the die you need for one off projects instead of every due costing you $300+

I highly doubt the dies will be interchangeable between different brand benders. Could be wrong but doubtful.

The reason I wanted whole number radius dies was for my tubing bending radius gauges. They’re made only for whole number radius dies.

CarterKraft

Red Skull Member

My boss

Well yeah of course. I meant that if you have a buddy with a JD2 bender and 1 3/4" die maybe don't buy the exact same die/bender he has offer to buy alternate size and then you could swap out and double your die count. This might be more applicable to fringe sizes, 1" square, 1.25" 1.625" etc.That may or may not work. Benders I had in the past like the one OP is talking about, use half dimensions not whole. What I mean is, their 1 3/4” tubing die has a radius of say 5.5”. I sold all that stuff for the JMR for two reasons. One, their arms are strong enough to bend serious thick wall DOM tubing. Secondly, their dies are whole number radius measurements i.e. 1 3/4” tubing die with a 5” radius.

I highly doubt the dies will be interchangeable between different brand benders. Could be wrong but doubtful.

The reason I wanted whole number radius dies was for my tubing bending radius gauges. They’re made only for whole number radius dies.

Toxocara

Member

- Joined

- Apr 11, 2024

- Member Number

- 7715

- Messages

- 8

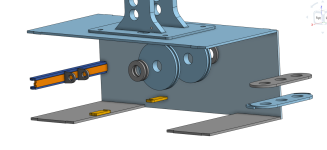

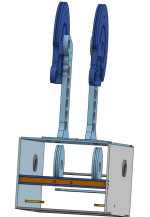

Well it's been a while, and boy has it been a journey. After quite a bit of searching, I managed to find where the measurements I needed had been posted all along. I had nearly finished my "final" version of my bender when I ran across a bender called the AW180 that a guy makes and sells and the idea is genius. Taking inspiration from that bender, I scrapped my first idea and created this. The bender uses a steel cable or high tension rope attached to hydraulic ram to turn the circular drive arms. The AW180 seems to be a fantastic bender, but seems limited in the ability to use smaller size dies and requires an electrically driven ram. Mine allows for all die sizes, makes use of the Harbor Freight air over hydraulic ram, has soring return, and a few other creature comfort upgrades that seem to be missing from the other bender. And it can be made entirely from 1/4" plate! I am having the laser guy at work cut everything for me as soon as he has the time. After I build and test it, I'll see about distributing my plans, and possibly selling weld-it-yourself kits.

Attachments

MigGunslinger

Red Skull Member

That is an interesting design. Reminds me of the horizontal one built on pirate years ago that used industrial chain and could one shot 180 degree bends.

edit: it was bugging me so I did some googling "homemade hydraulic chain driven bender" by ZAG

edit: it was bugging me so I did some googling "homemade hydraulic chain driven bender" by ZAG

Last edited:

Landslide

Red Skull Member

- Joined

- May 20, 2020

- Member Number

- 422

- Messages

- 1,483

Yeah, you wouldn’t catch me bending thick wall DOM with that grenade.Steel/aluminum oreo cookie.

JD2 Tube bender DIY – Mungruls Blog

mungrul.ie

Double Flute Round Nose Bit

7/8" Radius

1-3/4" Cutting Diameter

1-1/4" Cut Length

3" Overall Length

1/2" Shank

subybaja

E. Spengler

You think the bolts would let go, or just too much stress for the various plates? I could see it taco-ing with heavy-wall stuff for links...Yeah, you wouldn’t catch me bending thick wall DOM with that grenade.

Interesting design, that top plate does not bend? Seems like it would have quite the moment going through it which would cause it to buckle. Also how big of a cable are you using?Well it's been a while, and boy has it been a journey. After quite a bit of searching, I managed to find where the measurements I needed had been posted all along. I had nearly finished my "final" version of my bender when I ran across a bender called the AW180 that a guy makes and sells and the idea is genius. Taking inspiration from that bender, I scrapped my first idea and created this. The bender uses a steel cable or high tension rope attached to hydraulic ram to turn the circular drive arms. The AW180 seems to be a fantastic bender, but seems limited in the ability to use smaller size dies and requires an electrically driven ram. Mine allows for all die sizes, makes use of the Harbor Freight air over hydraulic ram, has soring return, and a few other creature comfort upgrades that seem to be missing from the other bender. And it can be made entirely from 1/4" plate! I am having the laser guy at work cut everything for me as soon as he has the time. After I build and test it, I'll see about distributing my plans, and possibly selling weld-it-yourself kits.

That is an interesting design. Reminds me of the horizontal one built on pirate years ago that used industrial chain and could one shot 180 degree bends.

edit: it was bugging me so I did some googling "homemade hydraulic chain driven bender" by ZAG

This is one of the coolest things I have seen in a while. I really want one.

Toxocara

Member

- Joined

- Apr 11, 2024

- Member Number

- 7715

- Messages

- 8

I don't think it will. It will be effectively 3/4" thick by stacking the 1/4" plates together and that's as thick as the long arms on the JD2 Model 32. Those arms would have far more strain on them with the added leverage I would think and they do fine. Here is a video of the AW180 I took the idea from. Watch his channel, he has a few videos showing it off and displaying his version's capabilities.Interesting design, that top plate does not bend? Seems like it would have quite the moment going through it which would cause it to buckle. Also how big of a cable are you using?

This is one of the coolest things I have seen in a while. I really want one.

As for cable, oddly enough, I believe I'll actually be using rope. It's a crazy strong plastic called Dyneema. It comes in different variants, but 1/4" thick rope of SK-90 Dyneema is rated at 12000 pounds tensile strength. With 2 ropes, it'll be plenty strong for a 8 ton Harbor Freight ram. The same size steel cable is rated to much less. The other huge benefit is that if and when it snaps, it stores very little energy because of it's low mass and is basically harmless. They use this for winch cables, ship rigging, rock climbing, etc. You braid it back into itself to create eyelets and such, no knots. It's crazy cool stuff. The AW180 bender uses it and I did a ton of research on YouTube about it. There's a channel called HowNot2 that does hydraulic strength tests on it and it seems awesome. Yeah, it might not be as abrasive resistant as cable, but in my hobbiest shop, I think it'll do fine. Maybe if this bender was getting used for 8 hours a day, cable would be a smarter option. But I really like the safety factor of it. I'm not an engineer, just a welder who can barely use some CAD software. So I'll take the margins of error where I can get them. XD

subybaja

E. Spengler

I don't think it will. It will be effectively 3/4" thick by stacking the 1/4" plates together and that's as thick as the long arms on the JD2 Model 32. Those arms would have far more strain on them with the added leverage I would think and they do fine. Here is a video of the AW180 I took the idea from. Watch his channel, he has a few videos showing it off and displaying his version's capabilities.

...

As for cable, oddly enough, I believe I'll actually be using rope.... So I'll take the margins of error where I can get them. XD

Synthetic rope is what all the cool 4x4 kids use on their winches, for the last 20 years.

Synthetic rope is what all the cool 4x4 kids use on their winches, for the last 20 years.Only the poors and olds use steel cable any more...