As with any of my personal projects, I never get the easy ones. Like hey, here is a bad injector, replace it and boom done. Nope. not me. not ever it seems.

So here I am. to update I got a contamination kit. Because it was the best deal compared to individual parts. So I just got the motorcraft kit. Thought I would install decent brand name parts and all my problems would be gone.

Started with replacing just the injectors and rails. Just for kicks wanted to see what happens. I did all that. Hooked up the forscan. Tried to start the truck and Nothing, no change in rail pressure. Still does not build rail pressure. At all. None.

I bled it plenty. Kept cycling the key as I was entering the IQA numbers. And nothing. Just like before. Not building rail pressure.

Only code is injector pressure too low while cranking.

honestly expected that because all of the testing I had done previous to tear down said it was a failed CP4.

So onto replacing the CP4. It went very well. I have been lucky all along, no stuck injectors, everything came apart just fine.

Finally get it all back together and absolutely no change. Crank no start, not building any rail pressure. None.

I start going through all the trouble shooting again. Testing the new PCV, VCV, bleeding, purging air.

Even tried some other things. Making sure my trouble codes were cleared before cranking. In doing that I am getting MAP code and Barometric sensor code because the top of the engine is still off.

So I hooked them up and let them lay there. Can't hurt right?

to my surprise after doing so the engine started to build rail pressure while cranking. first try was like 150 psi, second try was like 250, 3rd try was like 1500 psi. 4th try it started and ran. My rail pressure was running plenty high like 6k. but bouncing around. Then the engine died.

Immediately back to crank no start, no rail pressure.

No idea if the MAP and Baro sensor had anything to do with it. I really don't think it did. but things like that distract you just enough to lose sight of the goal.

I had noticed at one point when working on the engine that with the key on, the alternator was hot. So that got me to thinking about stray ac voltage. So I disconnected it. Have the charger on the truck anyway. So no need for an alternator right now.

For kicks I pulled the VCV to inspect. Of course it was clean. While I had it off I cycled the key and a ton of fuel shot out. So it is getting fuel to the vcv and pump. My core is long gone otherwise I would have swapped the VCV to see what happens.

Keep in mind I am working on this in my spare time so i come up with an idea and test it when I can.

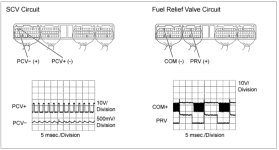

Started thinking about PCM. So i did my best to test that. I have 12v at the VCV. yellow wire. Even during cranking. On the blue wire I don't have an oscilloscope so I can't accurately test the PW. But I did watch the voltage change while cranking. It dropped to about 9v dc. to me this also said the PCM is trying to control the VCV and my wiring was good. I even tore apart the plug to the VCV and made sure the wires and connection points were good.

At some point I returned my PCM to stock programming. Like I said, just desperate at this point.

But regardless the PCM seems to be doing what it should. Communicating. Responding. Wiring seems to be good.

I had also removed my fuel cap before doing any of this testing. Cause you just never know. LOL.

Kind of a side note, I mentioned earlier in the thread that I had read, if you crack an injector line KOEO and fuel shoots into the air then you have a bad inlet suction valve. Well I have that with the new pump as well, so that is either BS or my new CP4 has a bad inlet suction valve as well.

So I think now I am at, a mechanically bad VCV. LPFP or maybe even something in the tank blocking flow, or faulty cp4.

Just seems strange to think I can run fuel into a bucket all day long but only have a problem with cranking the truck? I can't get past that. I have the FP gauge tapped to the windshield so I watch it just about every time I crank the engine or cycle the key.

I ordered another VCV. Be here later this week. I am about 50/50 that it will be the problem.

Kind of lean towards that because I have NO rail pressure. Usually you read about guys getting 200 psi or 900 psi or just building slow. I just get nothing, Nada. But that would mean my last VCV was bad too? Doesn't make sense either.