As the title states... What is everyone using? Do you like it or is there certain things you don't like about it? I'm mostly asking about the 400 dollar range notcher. Currently looking at the pro tools notcher but interested in what everyone else uses before I buy a new one.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What tube notcher do you use?

- Thread starter Sluggy

- Start date

JohnnyJ

Low Range Drifter

I have a Woodward Fab knockoff of the JD2 Notch Master. I picked it up as an open box unit and it was much cheaper than the JD2 by over $100 at the time. One thing that I noticed it can't do is offset notch like the JD2. It did take me years to notice it couldn't do this, so it's not something I need everyday.

www.woodwardfab.com

www.woodwardfab.com

but the original is cheaper unless they haven't updated the web site: JD2. Tube and Pipe Notchers

Hole Saw Pipe and Tube Notchers WFN6 - Woodward Fab

Buy WFN6 hole saw pipe and tube notcher at Woodward Fab official website. Comes with solid steel construction. Works 3/4" to 3" tubing (o.d.). Use with Any 1/2″ Hand Drill. Visit the website to know more product details.

but the original is cheaper unless they haven't updated the web site: JD2. Tube and Pipe Notchers

YotaAtieToo

Thick skull

I use the Rouge fab

VersaNotcher - Universal Tubing Notcher & Pipe Notcher | Rogue Fabrication

It's a little different than most of the other notchers. I think angle changes are faster. Offsets are kinda a pain, but they are no matter what. I also like that they use their own arbors and will sell you a bunch for cheap so you can just leave them in their various sizes.

Another trick, not exclusive to the Rouge fab unit, I've heard on here was using an 1/8-1/4" bigger hole saw than the tube. Less flashing and cuts through faster. Also leaves a nice small gap on the sides for weld.

VersaNotcher - Universal Tubing Notcher & Pipe Notcher | Rogue Fabrication

It's a little different than most of the other notchers. I think angle changes are faster. Offsets are kinda a pain, but they are no matter what. I also like that they use their own arbors and will sell you a bunch for cheap so you can just leave them in their various sizes.

Another trick, not exclusive to the Rouge fab unit, I've heard on here was using an 1/8-1/4" bigger hole saw than the tube. Less flashing and cuts through faster. Also leaves a nice small gap on the sides for weld.

92 Green YJ

General Lee Jeep

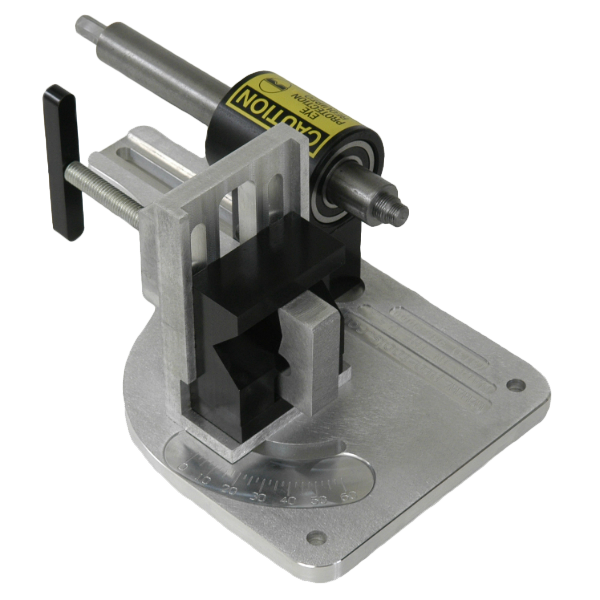

I bought and use this one. It’s been pretty good and has worked well for me.

www.trick-tools.com

www.trick-tools.com

ATN100, Buildpro Tube and Pipe Notcher, Hole Saw Notcher

Designed to work with Buildpro and other fixturing tables, use this hole saw notcher to make precise copes in tubing, pipe, and square

Weasel

Red Skull Member

no clue what this is. Build a crap load of cages though.

I'd like the find an abrasive grinder for notching but seems like they are not as flexible use wise..

I'd like the find an abrasive grinder for notching but seems like they are not as flexible use wise..

72Pstroke

Well-known member

- Joined

- May 24, 2020

- Member Number

- 1332

- Messages

- 210

I have on of these for square cut notches.

irvansmith.com

I built this one for miter cut tubing.

irvansmith.com

I built this one for miter cut tubing.

Down for Maintenance : Irvan-Smith, Inc.

Irvan-Smith, Inc. : Down for Maintenance - Odds & Ends,Tools & Equipment,Race Car Parts,Pit Equipment,Fasteners,Cleaners,Tires & Wheels,Storage Solutions,Rotex Punch & Accessories,Pop-Up Canopies,Longacre Racing Products,Used Equipment,Software,Services,Carts & Wagons,Blowout Specials!,

CarterKraft

Red Skull Member

Right on guys, thank you for all the replies. I was checking this one out but I've was also scoping out the one 92 green yj recommended. Time for more research...

CarterKraft

Red Skull Member

Looks like another knock off of the American made Notch Master....

Same as Woodward Fab.

It just doesn't feel right to me.

American iron in the shop seems to last forever.

Same as Woodward Fab.

It just doesn't feel right to me.

American iron in the shop seems to last forever.

TTMotorsports

Red Skull Member

I have a Baileigh TN-250 and got it 8 years ago and never had a problem. Works awesome.

BUT i recently got an ameribrade 2x72 belt sander with their small wheels and it can do everything the hole saw notcher can do a little faster AND more. No need to holesaw notch then grind clean with sander, the belt sander is a 1 stop shop.

BUT for the price of the hole saw notcher I wouldn't replace it for sure. Much cheaper than the belt sander BUT i use it for much more stuff and use it everyday where the notcher doesn't get used but once in a while when that time of the project is needed.

BUT i recently got an ameribrade 2x72 belt sander with their small wheels and it can do everything the hole saw notcher can do a little faster AND more. No need to holesaw notch then grind clean with sander, the belt sander is a 1 stop shop.

BUT for the price of the hole saw notcher I wouldn't replace it for sure. Much cheaper than the belt sander BUT i use it for much more stuff and use it everyday where the notcher doesn't get used but once in a while when that time of the project is needed.

X2 on the rogue where a notcher is appropriate. Mines built many cages, bumpers, etc without issue. I have it mounted on a stand that’s bolted through the floor instead of the usual home show vise mount. It handles an impressive amount of weight hanging off one side. The notches to do box tube have come in handy too.

Etyler2

Your kind of Asshole

Saw those a couple years ago at KOH. My boss bought one with everything. He likes it also.

I have a Baileigh TN-250 and got it 8 years ago and never had a problem. Works awesome.

BUT i recently got an ameribrade 2x72 belt sander with their small wheels and it can do everything the hole saw notcher can do a little faster AND more. No need to holesaw notch then grind clean with sander, the belt sander is a 1 stop shop.

BUT for the price of the hole saw notcher I wouldn't replace it for sure. Much cheaper than the belt sander BUT i use it for much more stuff and use it everyday where the notcher doesn't get used but once in a while when that time of the project is needed.

kbenz

Well-known member

I use the cheap one from northern tool. needs a few mods but i've notched a lot of 1.250 sch40 pipe with it over the past few years

TTMotorsports

Red Skull Member

I had a harbor freight notcher for years and it worked BUT the bushings would get sloppy and hole saws wouldn't last very long because of that.

kbenz

Well-known member

gotta throw that pin away and put grease fittings inI had a harbor freight notcher for years and it worked BUT the bushings would get sloppy and hole saws wouldn't last very long because of that.

TTMotorsports

Red Skull Member

yeah I made a new shaft support with some needle bearings and tubing but honestly with all that work it would be better off time/money ahead with buying a better one so I did with the baileigh unit.

SomeGuyFromOlympia

Well-known member

- Joined

- May 31, 2020

- Member Number

- 1706

- Messages

- 859

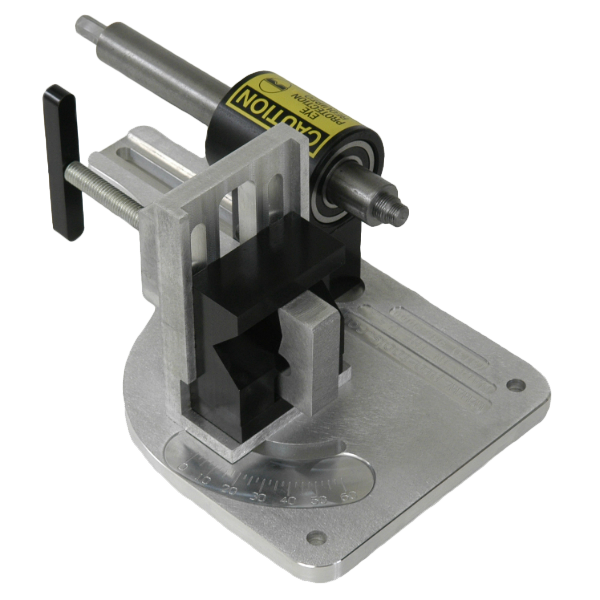

Pro+ Pipe and Tube Notcher

Specs Round Tube Minimum Outside Diameter (OD): 1/2" (12.7 mm) Maximum Outside Diamter (OD): 2" (50.8 mm) Pipe Minimum Size: NPS 1/4 (DN 8) Maximum Size: NPS 1-1/2 (DN 35) Other Specifications Notch Angle: 0degrees-60degrees Offset Notching: Up to 1/2 the OD of your tube or pipe...

Been running this for years, still holding up

YotaAtieToo

Thick skull

yeah I made a new shaft support with some needle bearings and tubing but honestly with all that work it would be better off time/money ahead with buying a better one so I did with the baileigh unit.

The harbor freight one is almost better than nothing. Mine barely lasted through 2 cages before the bushing kept walking out, and it was definitely sloppy.

I was only using it for simple ~90-60* notches, anything else, I use my band saw.

Etyler2

Your kind of Asshole

Built my exo with one and for $50 it was worth it.

The bushings are toast though.

+\- 1/8” cages are good for most of us.

Jimbo be wanting a nice one.

The bushings are toast though.

+\- 1/8” cages are good for most of us.

Jimbo be wanting a nice one.

I had a harbor freight notcher for years and it worked BUT the bushings would get sloppy and hole saws wouldn't last very long because of that.

TTMotorsports

Red Skull Member

Yeah I learned how to chop saw and grinder notch for years before I even had the harbor freight notcher. Learn that and you won't need a notcher to do most jobs.

YotaAtieToo

Thick skull

Yeah I learned how to chop saw and grinder notch for years before I even had the harbor freight notcher. Learn that and you won't need a notcher to do most jobs.

I've done a lot of tube work with no notcher and 99% of it was with a vertical bandsaw.

That being said, it's nice to be able to measure your angle, set the single in the notcher, hit it with a flap disc and you're done.

simmons3067

Well-known member

- Joined

- Aug 22, 2021

- Member Number

- 4294

- Messages

- 131

I have a baileigh TN-250 and like it. I have used the JD2 and pro tools notchers. The baileigh is much nicer but the others work fine. I like the way the Baileigh clamps the tube and also the ability to do a steeper angle.

SomeGuyFromOlympia

Well-known member

- Joined

- May 31, 2020

- Member Number

- 1706

- Messages

- 859

pro tools

used it forever

have it mounted to the floor on a stand, corded drill stays on it

used it forever

have it mounted to the floor on a stand, corded drill stays on it

pennsylvaniaboy

make fullsizes great again

- Joined

- Jun 27, 2020

- Member Number

- 2192

- Messages

- 901

JD2 notch master here....Plan to buy the GOAT and the reach around at some point.

Pro+ Pipe and Tube Notcher

Specs Round Tube Minimum Outside Diameter (OD): 1/2" (12.7 mm) Maximum Outside Diamter (OD): 2" (50.8 mm) Pipe Minimum Size: NPS 1/4 (DN 8) Maximum Size: NPS 1-1/2 (DN 35) Other Specifications Notch Angle: 0degrees-60degrees Offset Notching: Up to 1/2 the OD of your tube or pipe...pro-tools.com

Been running this for years, still holding up

That's the same one I have, and mine is at least 18yrs old. I've built dozens of cages with that notcher and other than swapping to a SWAG shaft after I stripped the original, its been flawless.

SomeGuyFromOlympia

Well-known member

- Joined

- May 31, 2020

- Member Number

- 1706

- Messages

- 859

been happy with mine too, all the anodizing is worn offThat's the same one I have, and mine is at least 18yrs old. I've built dozens of cages with that notcher and other than swapping to a SWAG shaft after I stripped the original, its been flawless.

I did throw it in the mill and extend the arc though now that I think about it

still haven't striped the shaft, but I am pretty easy on it, the drill I use likes to kick my ass

AlxJ64

Rust is Paint

I've got the TN250 from Baileigh tools as well. Picked it up when they very first came out and have built a number of cages with it. The degree wheel isn't the greatest on it but the vise works great, especially for notching in a bend. I have some large diameter roughing end mills on hand that I've daydreamed about using for notching. May have to do it once the Cinci Mill gets wired up.

Brad

Jackass

I used a regular pro tools one 15 years ago and it was nothing special. Friend has a JD2 from the same era. I like that it has a nylon set screw to hold the shaft in place while you line up your tube. At work I have a Woodward fab WFN6 notcher. It does 3” capacity so it will do 2” pipe. Main reason I had them buy that one.