RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,733

For those with the XD9000i this is what I’m using as instructions.

Also, the parts diagram for my winch (Serial Number 667219)

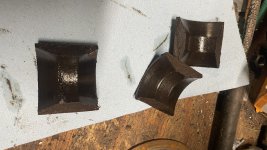

According to the internet the gaskets (part number 13848) are sold individually and the two pack is 98274. The individual gasket is online for $12-37 while the two gasket kit is $12-20. These are for the housing around the ring gear. Mine was ‘stuck like Chuck’ until a healthy supply of PB blaster was used to free it up along with a deadblow mallet.

I wiped out the housing before taking the photo. There were balls of grease in the bottom.

There is a correct way to install this gear. The groved side faces towards the spool. Oddly, this doesn’t match the Warn parts diagram. It’s how mine came out so maybe it’s was installed wrong. It matches the Wandering Trail link above. If it’s backwards the winch won’t disengage so this is actually important.

Also, the parts diagram for my winch (Serial Number 667219)

According to the internet the gaskets (part number 13848) are sold individually and the two pack is 98274. The individual gasket is online for $12-37 while the two gasket kit is $12-20. These are for the housing around the ring gear. Mine was ‘stuck like Chuck’ until a healthy supply of PB blaster was used to free it up along with a deadblow mallet.

I wiped out the housing before taking the photo. There were balls of grease in the bottom.

There is a correct way to install this gear. The groved side faces towards the spool. Oddly, this doesn’t match the Warn parts diagram. It’s how mine came out so maybe it’s was installed wrong. It matches the Wandering Trail link above. If it’s backwards the winch won’t disengage so this is actually important.