seebrookmeyer

Well-known member

Figured I should start an actual project thread on my poo pile, the Turdburglar

Here are some more details of the car as it was when I purchased it...

1986 Extra Cab

rebuilt 22re (about 1,000 miles on the motor since rebuild)

Bomb Proof motor mounts

Big ol' stinger up front with a 9000b warn winch

rock sliders and tube rear bumper

Marlin crawl box

4.70 in the rear case

Bomb Proof t case mount

4.88's with ARB air lockers front and rear

Chromo Shafts front and rear

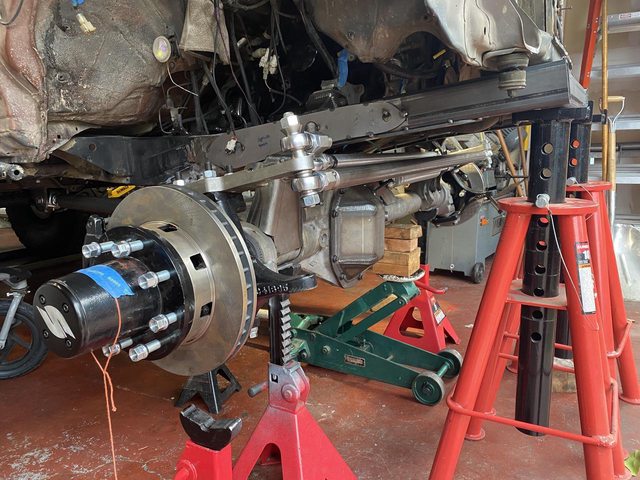

10 bolt front axle, disc brakes

Toyota rear, with drums

37" Old style MTR's

Steel wheels

interior cage

Master craft seats with harnesses

rock lights

beat for bumping Party in the USA

CB radio

Since purchasing I have been able to wheel this thing a handful of times. Maiden voyage was rubicon for Memorial Weekend with the Poly Goats. Truck worked well, was mostly just getting a feel for it, in particular wheeling with dual cases. Lots of lever to pull, but I'm getting a lot more comfortable with it and enjoying it a lot more.

improvements since buying

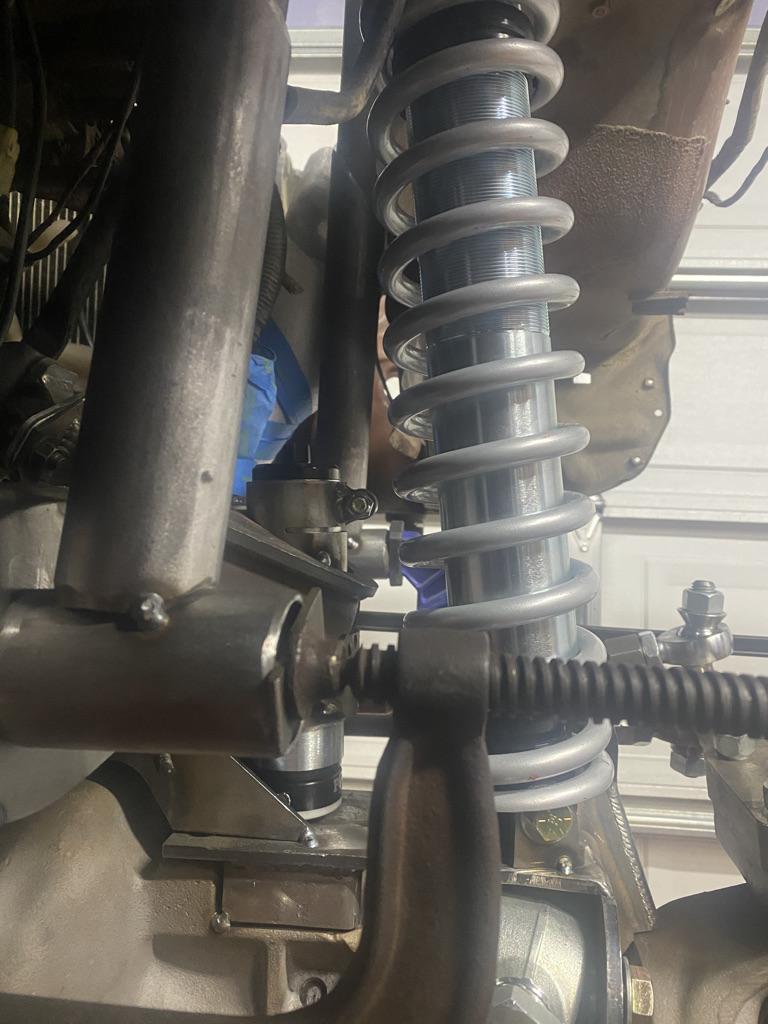

-14" 2.0 smooth bodies up front

-spare tire carrier with 12" 2.5 smooth bodies mounted off the back of this, with hi-lift mount and soon to be a baja basket on top

-15" TR beadlocks (snapped a few wheel studs off in the process of removing the old wheels, which led to the discovery of completely blown out seals)

-freshly serviced rear end, new seals, brake pads and wheel studs

-some sweet pink interior lights that look like a Tijuana strip club

on the list still

-not a 10 bolt front end, not sure what it will get replaced or the timeline for this but I would like to get rid of it sooner rather than later. Either back to toyota axle or possibly a 60 or something similar with the goal to keep it close to toyota width

-transmission needs some loving, countershaft bearing is pretty much shot and getting louder each trip, hoping to make it out of KOH this coming weekend and have it be a problem before summer wheeling starts

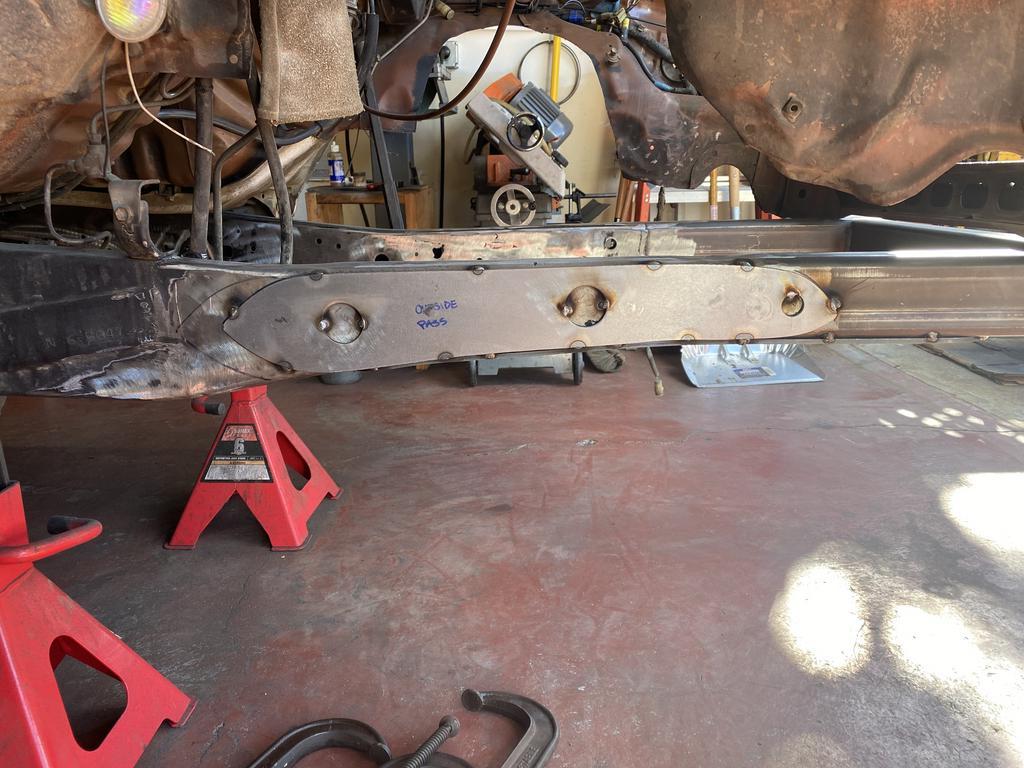

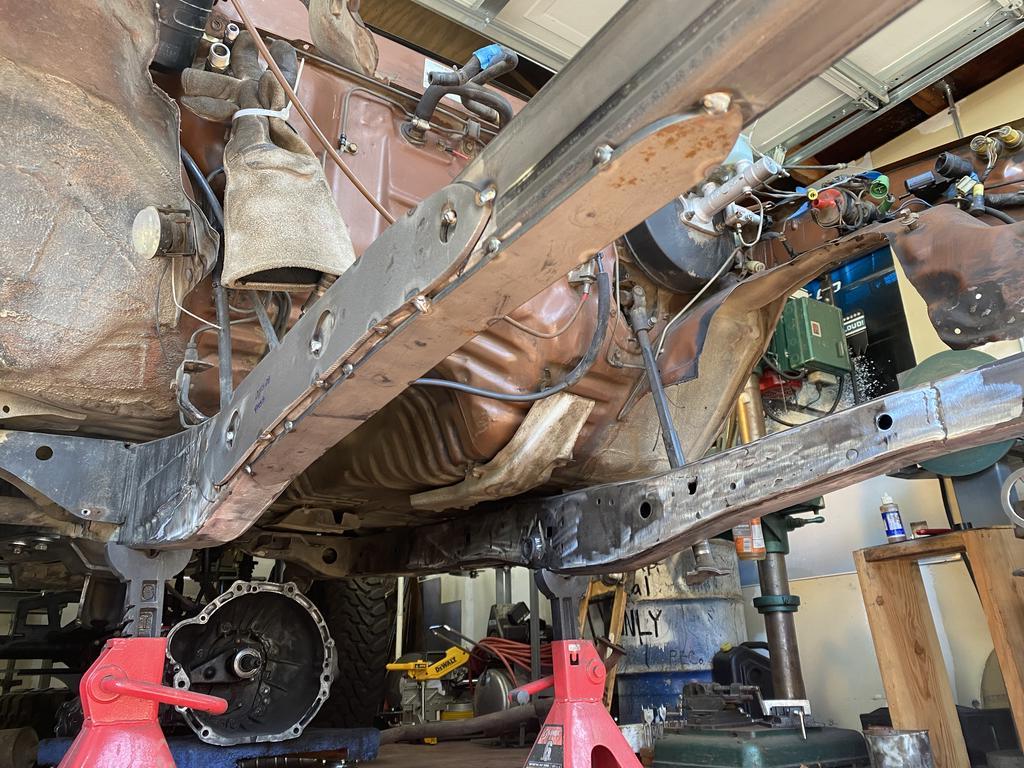

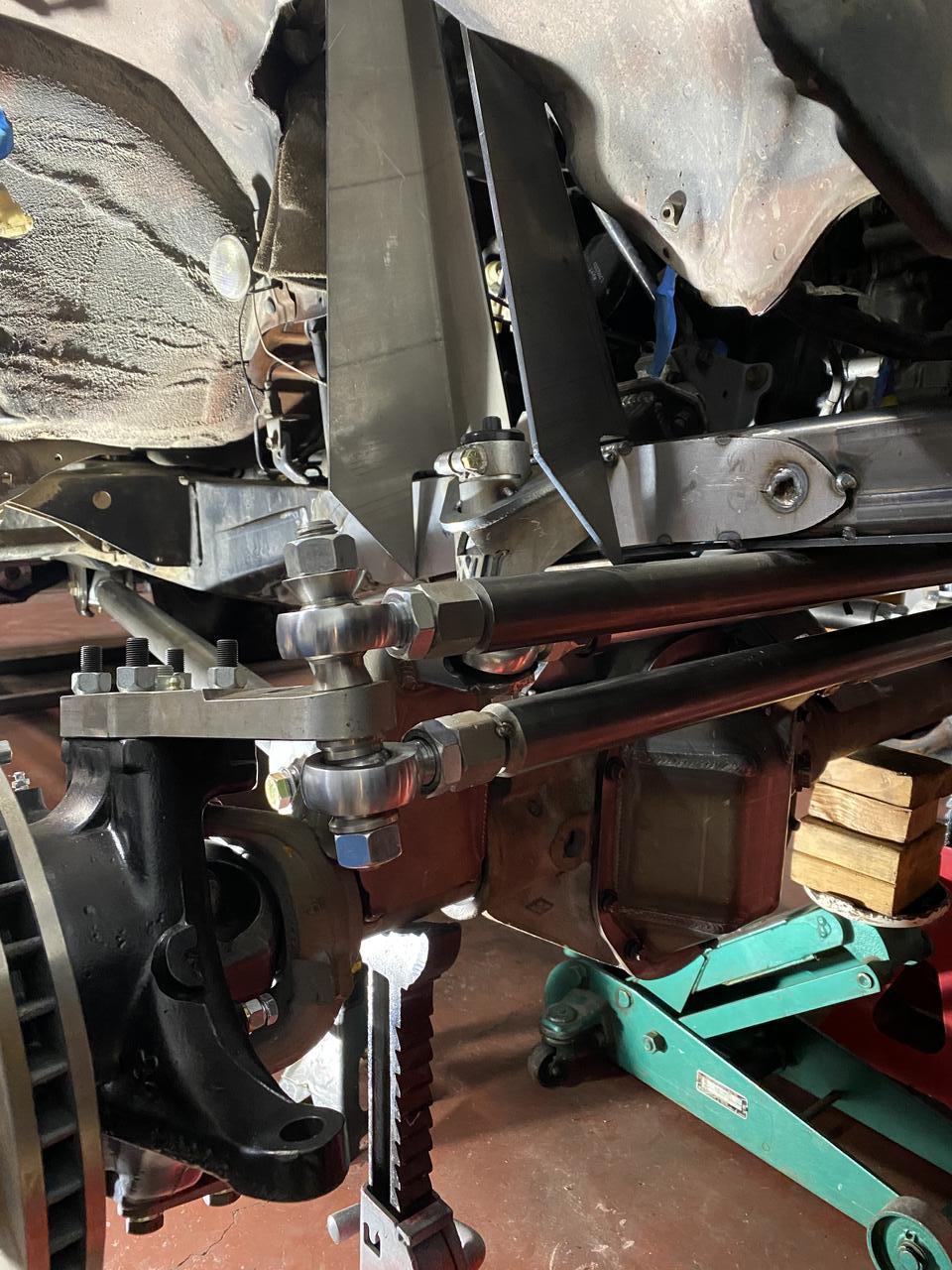

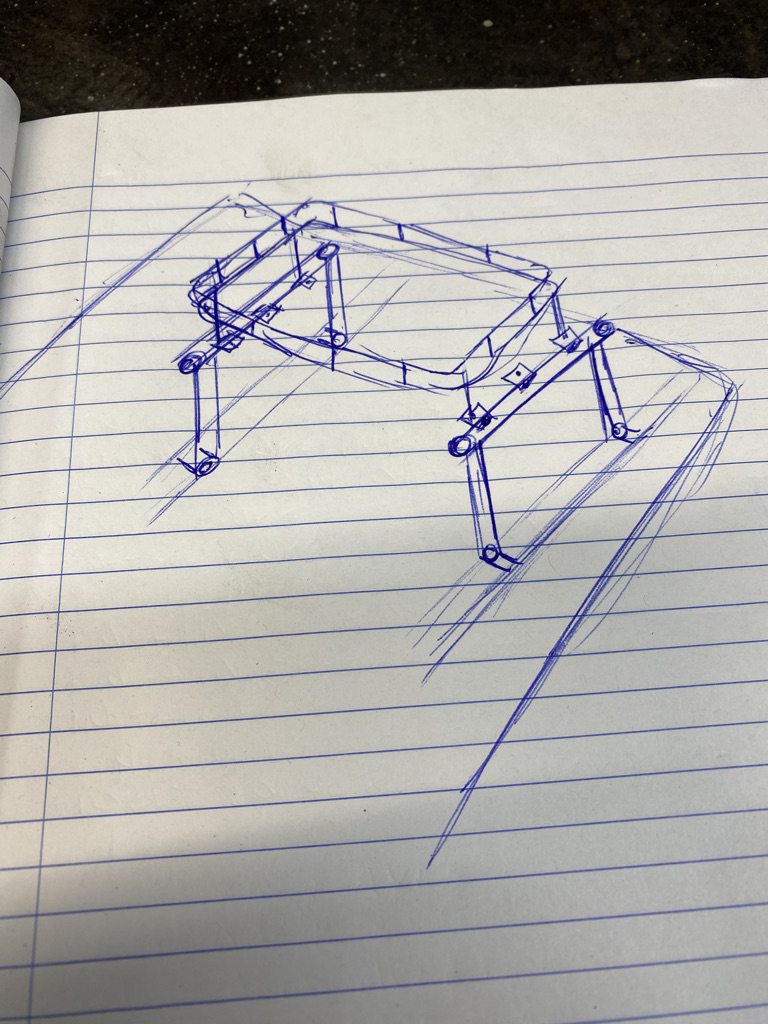

-new tranny/transfer case crossmember, current one hangs pretty low so I would like to get something up a little higher and build some skids off of it

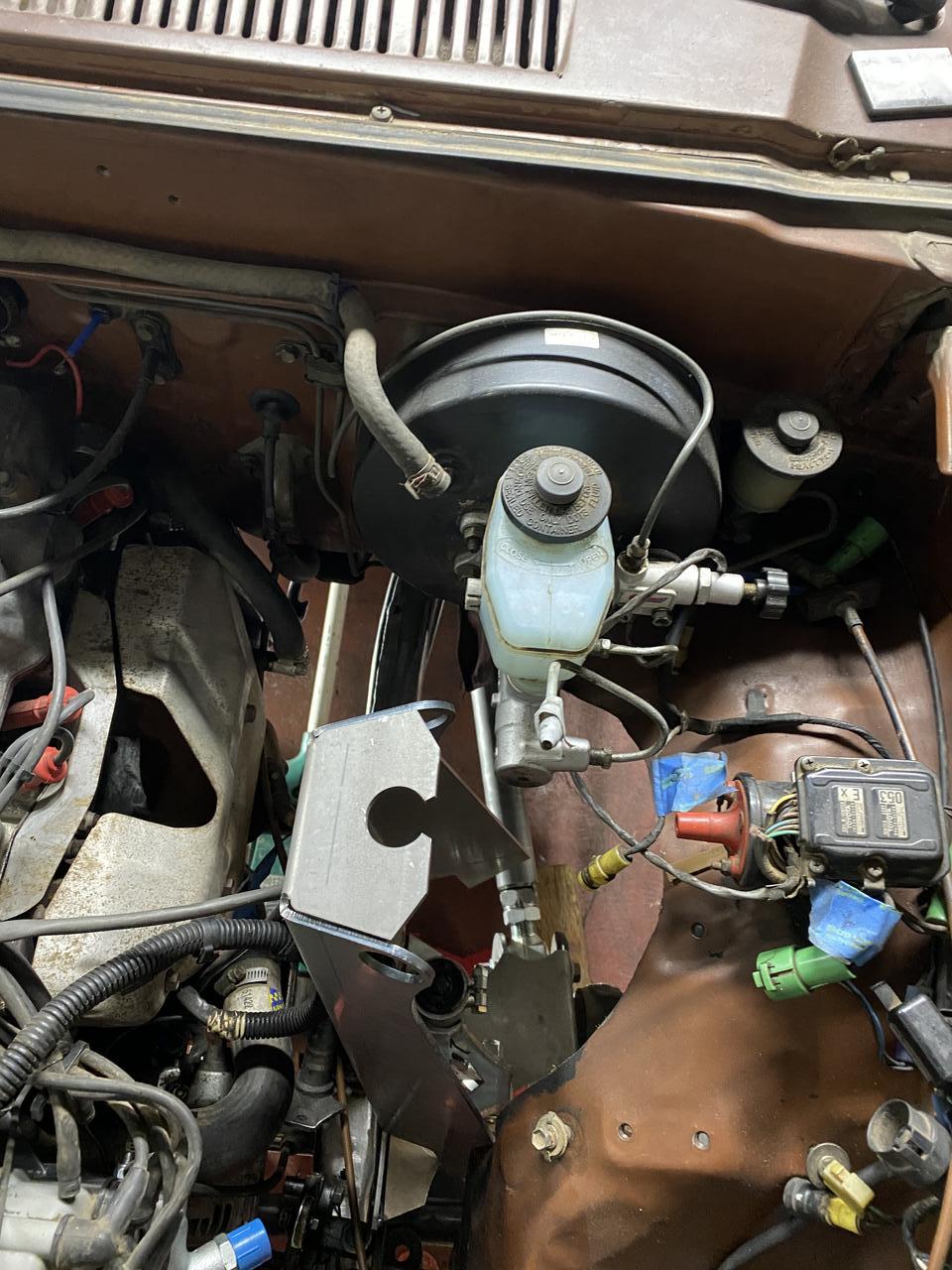

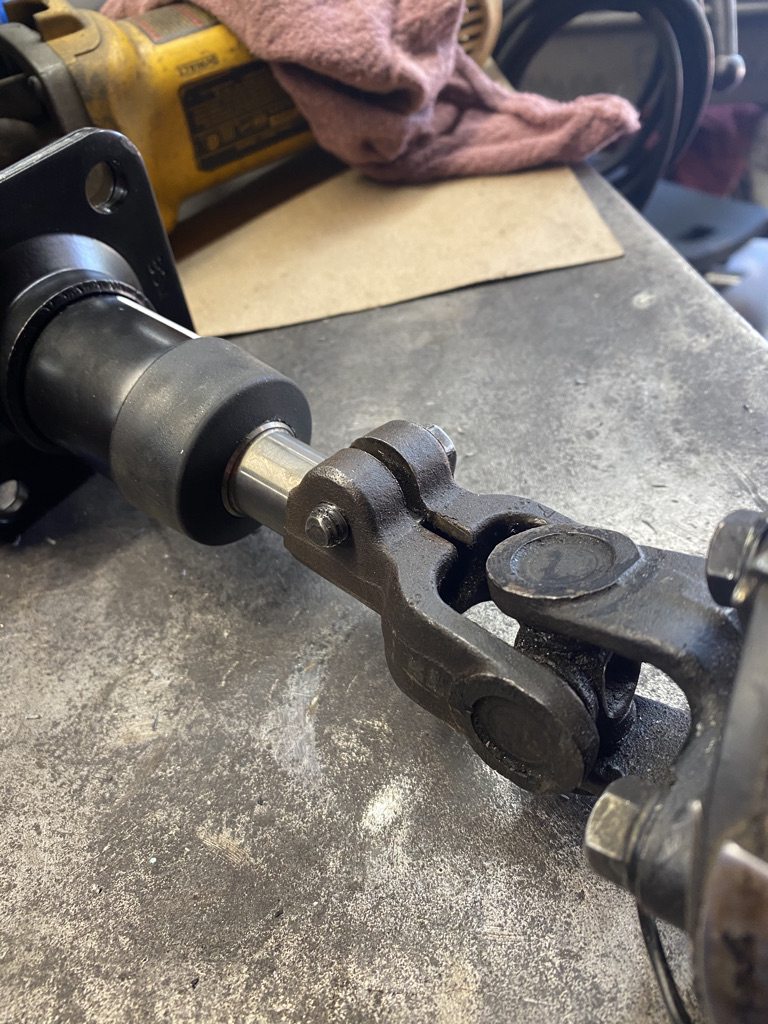

-clean up electrical, engine bay and interior

-this list is pretty much endless and will continue to grow with every trip.

Here are some more details of the car as it was when I purchased it...

1986 Extra Cab

rebuilt 22re (about 1,000 miles on the motor since rebuild)

Bomb Proof motor mounts

Big ol' stinger up front with a 9000b warn winch

rock sliders and tube rear bumper

Marlin crawl box

4.70 in the rear case

Bomb Proof t case mount

4.88's with ARB air lockers front and rear

Chromo Shafts front and rear

10 bolt front axle, disc brakes

Toyota rear, with drums

37" Old style MTR's

Steel wheels

interior cage

Master craft seats with harnesses

rock lights

beat for bumping Party in the USA

CB radio

Since purchasing I have been able to wheel this thing a handful of times. Maiden voyage was rubicon for Memorial Weekend with the Poly Goats. Truck worked well, was mostly just getting a feel for it, in particular wheeling with dual cases. Lots of lever to pull, but I'm getting a lot more comfortable with it and enjoying it a lot more.

improvements since buying

-14" 2.0 smooth bodies up front

-spare tire carrier with 12" 2.5 smooth bodies mounted off the back of this, with hi-lift mount and soon to be a baja basket on top

-15" TR beadlocks (snapped a few wheel studs off in the process of removing the old wheels, which led to the discovery of completely blown out seals)

-freshly serviced rear end, new seals, brake pads and wheel studs

-some sweet pink interior lights that look like a Tijuana strip club

on the list still

-not a 10 bolt front end, not sure what it will get replaced or the timeline for this but I would like to get rid of it sooner rather than later. Either back to toyota axle or possibly a 60 or something similar with the goal to keep it close to toyota width

-transmission needs some loving, countershaft bearing is pretty much shot and getting louder each trip, hoping to make it out of KOH this coming weekend and have it be a problem before summer wheeling starts

-new tranny/transfer case crossmember, current one hangs pretty low so I would like to get something up a little higher and build some skids off of it

-clean up electrical, engine bay and interior

-this list is pretty much endless and will continue to grow with every trip.

Last edited: