Clb

another toyota from P.R.K

Cliffs

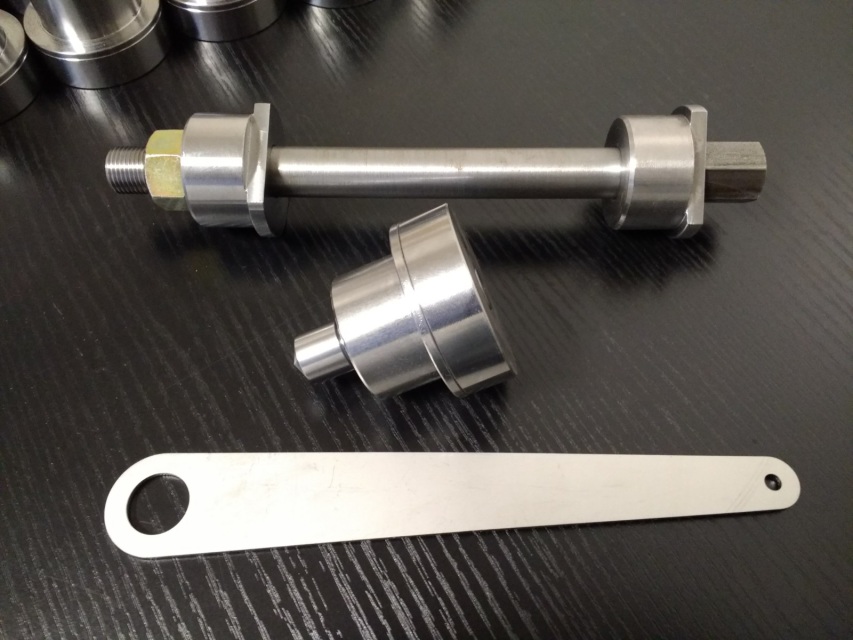

83 S.A. Fresh bearings and seals diff out to hubs, +- 2500 miles on the whole build (I remember a diy hack on the old place for making the sst tool.)

Looks like my indie left some tension off of them and now I got death wobble purty bad....

jap trunnion bearings, new wheel bearing that I've snugged up twice now hoping to fix it.

Rod ends and steering box are tight.

my indie is closed for the weekend, so I figured to do some research till Monday.

Anyone have the sst and willing to rent it out?

Any tips tricks? I know there are a lot of you that dealt with this before.

thanx fer lookin.

Cb

83 S.A. Fresh bearings and seals diff out to hubs, +- 2500 miles on the whole build (I remember a diy hack on the old place for making the sst tool.)

Looks like my indie left some tension off of them and now I got death wobble purty bad....

jap trunnion bearings, new wheel bearing that I've snugged up twice now hoping to fix it.

Rod ends and steering box are tight.

my indie is closed for the weekend, so I figured to do some research till Monday.

Anyone have the sst and willing to rent it out?

Any tips tricks? I know there are a lot of you that dealt with this before.

thanx fer lookin.

Cb

marlin dayum...

marlin dayum...

not my style.

not my style. no name arms...

no name arms...