zerobalance

Well-known member

Looking for some direction on this. I'm building a protools 105 bender clone. I had some 1/2" drops around, so we cut out arms.

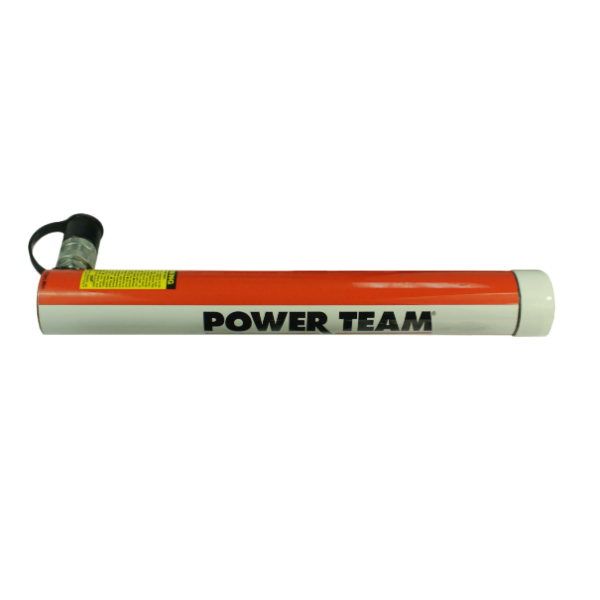

I'm trying to determine a cylinder to use on it. I know all about using the HF air over hydro, but I'm looking to go full hydro and use the pump I have for my small car lift to run it. Protools sells a SPX ram for them, but they are silly expensive. This is the one that protools sells for the conversion.

pro-tools.com

pro-tools.com

I'm looking at buying one of these

Am I missing something or will that cheap one work fine? I know the SPX one has a spring to retract it, which I can add externally. Is it worth doing all this, or should I just use the HF ram? I'm not going to be doing a ton of tube work, but I am building at least one cage in the next year.

I'm trying to determine a cylinder to use on it. I know all about using the HF air over hydro, but I'm looking to go full hydro and use the pump I have for my small car lift to run it. Protools sells a SPX ram for them, but they are silly expensive. This is the one that protools sells for the conversion.

105 SD/HD Bender 10-Ton SPX Hydraulic Cylinder 14" Stroke

Description Use with our 105 Heavy Duty tube bender to convert your bender to hydraulic (Hydraulic mounting kit required 10-Ton Capacity 14 1/8" Stroke Maximum sized springs speed piston return and increase spring life Made in the USA and completely serviceable Lead Time Lead times vary by...

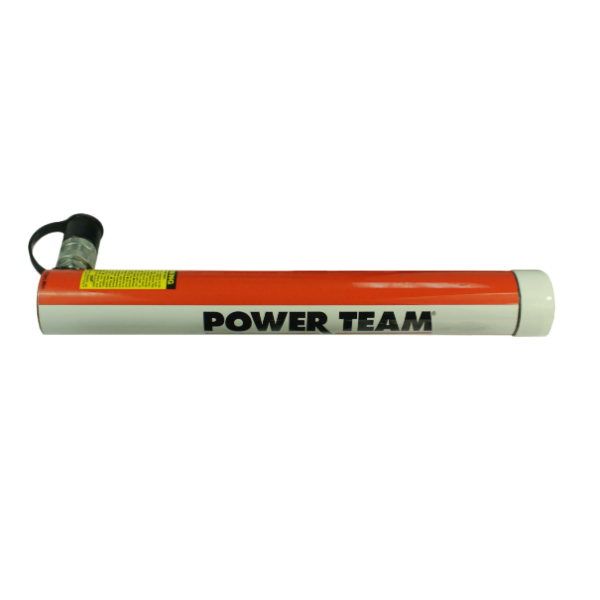

I'm looking at buying one of these

2.5x16x1.125 Double Acting Hydraulic Cylinder Lion 9-12282-2516 | eBay

Double acting hydraulic cylinder. Double Acting. Barrel Thickness 0.1875". Pin Hole 1". Outside Width 2.42". Rod End Clevis. END MOUNTINGS.

www.ebay.com

Am I missing something or will that cheap one work fine? I know the SPX one has a spring to retract it, which I can add externally. Is it worth doing all this, or should I just use the HF ram? I'm not going to be doing a ton of tube work, but I am building at least one cage in the next year.