You need to go out and get 2 40lb sacks of sand. One that's sharp, and one that has been tempered over time to be more spherical in grain.

Once you have acquired the sand, make sure you do this in a remote parking lot somewhere (a lot of sand is going to come out the tail pipe) and bring a buddy to help.

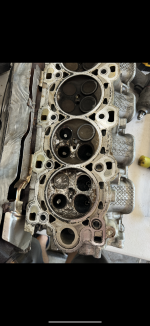

Start by removing the air cleaner assy off the intake. Have a buddy start the car and rev it to just under 500RPM below redline. SLOWLY start pouring in the "sharp" sand. This is what we call a Stage 1 port and polish, and honestly, it does most of the work enlarging the holes in the heads.

Secondly, after you have got through most of the first bag, pop open the second bag and repeat. This will polish up everything and remove the sharp edges created by the other sand.

If you want showroom quality, you can also finalize with a bottle of talcum powder in the same fashion. You can expect a smooth mirror finish.

EDIT: I forgot to add, you may want to purchase your sand sooner than later. Even if you don't use it now. Apparently there is a worldwide sand shortage.

The heads are still running today. Been used in a pretty stock application.

The heads are still running today. Been used in a pretty stock application.