Skinny

Well-known member

- Joined

- Feb 28, 2023

- Member Number

- 6236

- Messages

- 461

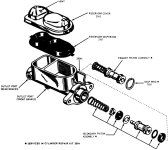

Long story short I'm trying to get a different MC on my S10 project. I'm using an MC from a 99 C3500 which is a Dorman M630028. It has a 1/4 line 9/16-18 fitting on the primary and a 3/16 line 1/2-20 on the secondary.

I am mating this to a PV4 Disc/Disc combination valve. It has a 1/2-20 on the primary and 7/26-24 on the secondary but it seems like the tube sizing is opposite.

Attached is a diagram of what I have for sizing. I can certainly make a set of stubs that will mate both ends to what sizes they are. But it seems like the size of the flare is made for the opposite size.

If I get an adapter to make the thread size work the tube size is off no matter what I do.

Should I just convert all fittings to AN and just have a pair or short stub lines made to eliminate this issue? Thoughts?

I am mating this to a PV4 Disc/Disc combination valve. It has a 1/2-20 on the primary and 7/26-24 on the secondary but it seems like the tube sizing is opposite.

Attached is a diagram of what I have for sizing. I can certainly make a set of stubs that will mate both ends to what sizes they are. But it seems like the size of the flare is made for the opposite size.

If I get an adapter to make the thread size work the tube size is off no matter what I do.

Should I just convert all fittings to AN and just have a pair or short stub lines made to eliminate this issue? Thoughts?