707offroad

Bro-tastic

- Joined

- May 19, 2020

- Member Number

- 280

- Messages

- 33

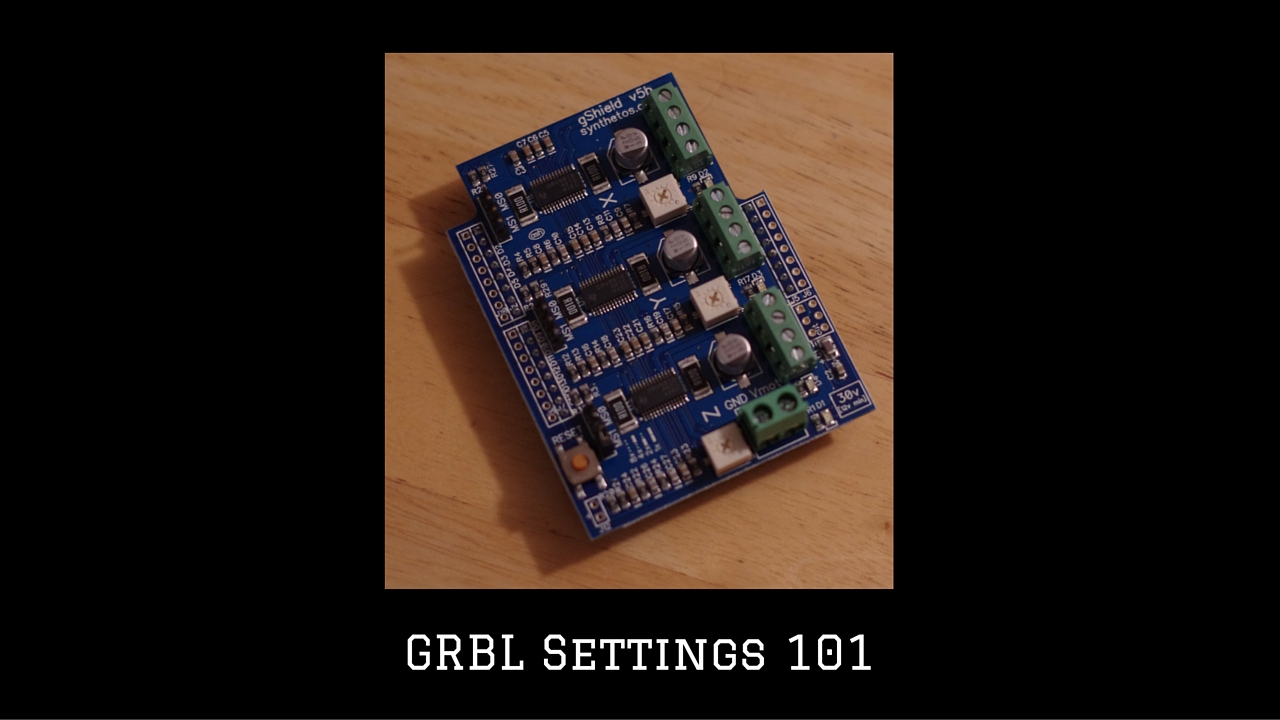

My friend gave me an old MAXNC 10 and I've retrofitted some small nema 17 steppers and a Sainsmart prover grbl controller.

I'm trying to get the stepper motors calibrated and I really have no idea what i'm doing.

I've tried changing the values for $100, $101, and $102. but I don't fully understand what i'm doing.

my stepper motors have a 1.8 step angle

leadscrews are 1/4-20 allthread

What values should i be changing

![IMG_4484[3].JPG IMG_4484[3].JPG](https://irate4x4.com/attachments/img_4484-3-jpg.645503/) ?

?

Thank you in advance

707

I'm trying to get the stepper motors calibrated and I really have no idea what i'm doing.

I've tried changing the values for $100, $101, and $102. but I don't fully understand what i'm doing.

my stepper motors have a 1.8 step angle

leadscrews are 1/4-20 allthread

What values should i be changing

Thank you in advance

707