I was looking at going this route for the flaring - heard good things about it:

Better writeup on Eastwood's site:

Create 45 and 37 Degree flares in 5 sizes of tubing

www.eastwood.com

It's been a while since I was looking at all this stuff, but I was originally looking at getting the flaring tool, some decent benders, tube straighter and good deburring/reaming tool and send it.

To those who have done it, ss tube nuts or mild steel? Issues with galling even thought you used anti seize or no biggie?

Cool that G&J offers annealed tube - will look into that. Who's annealed their own? Just heat up red hot over a purge box, or what?

Why not just sand it all and paint it?

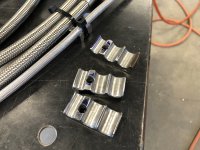

The larger nature of these is a lot easier to square up on the side of the frame rail and tack on, as opposed to bending washers or little individual brackets and tack every single one in place and keep everything straight. Same with the single brakeline brackets, since they're still square, although smaller:

The larger nature of these is a lot easier to square up on the side of the frame rail and tack on, as opposed to bending washers or little individual brackets and tack every single one in place and keep everything straight. Same with the single brakeline brackets, since they're still square, although smaller: