I'm happy with my new Lincoln 180.

mine treated me good for over 10yrs

I'm happy with my new Lincoln 180.

Hobart owns Miller. https://www.hobartbrothers.com/abou... family-owned,company of Miller Electric Mfg. Hobart is selling Miller's previous model versions that were rebranded. Miller puts out the flashy newness, Hobart sells the slightly older version/tech with the bugs worked out for alot less. Exact same stuff inside. Course if you just like the blue paint job.....

I have three Hobarts.

sometimes Hobart gets plastic parts instead of metal on the millers, there are a couple more corners cut than just being older style.

that said, I own and recommend Hobart all day long

From my reading, the current 210’s have a metal feed roller setup, as well as the better quality gun and ground clamp.

still, when looking at used equipment, something to be aware of.

still, when looking at used equipment, something to be aware of. nicestill, when looking at used equipment, something to be aware of.

granted, for a home or hobbyist or even light industrial use, not a deal breaker

A cheap inverter won't be as "smooth" of an arc as a transformer machine but it will weld just fine. I would have zero qualms about sticking together shit my life depended on with a HF welder I bought an hour prior. If you can weld worth a shit you will know what's up the second you strike an arc. Some of the fancy pants features may be lacking but if you are really that hard up for a welder it shouldn't matter.Bump, looking for a welder in the same category, with a catch. I need to have a new mig welder in my hand by the end of the weekend. I was at my local welding store yesterday, and they were telling me it would be at least a month to get anything into the store due to the current supply chain struggles, so I'm in a position where I may be forced to buy an off brand import just to have it here in a timely fashion so I can get product out the door next week.

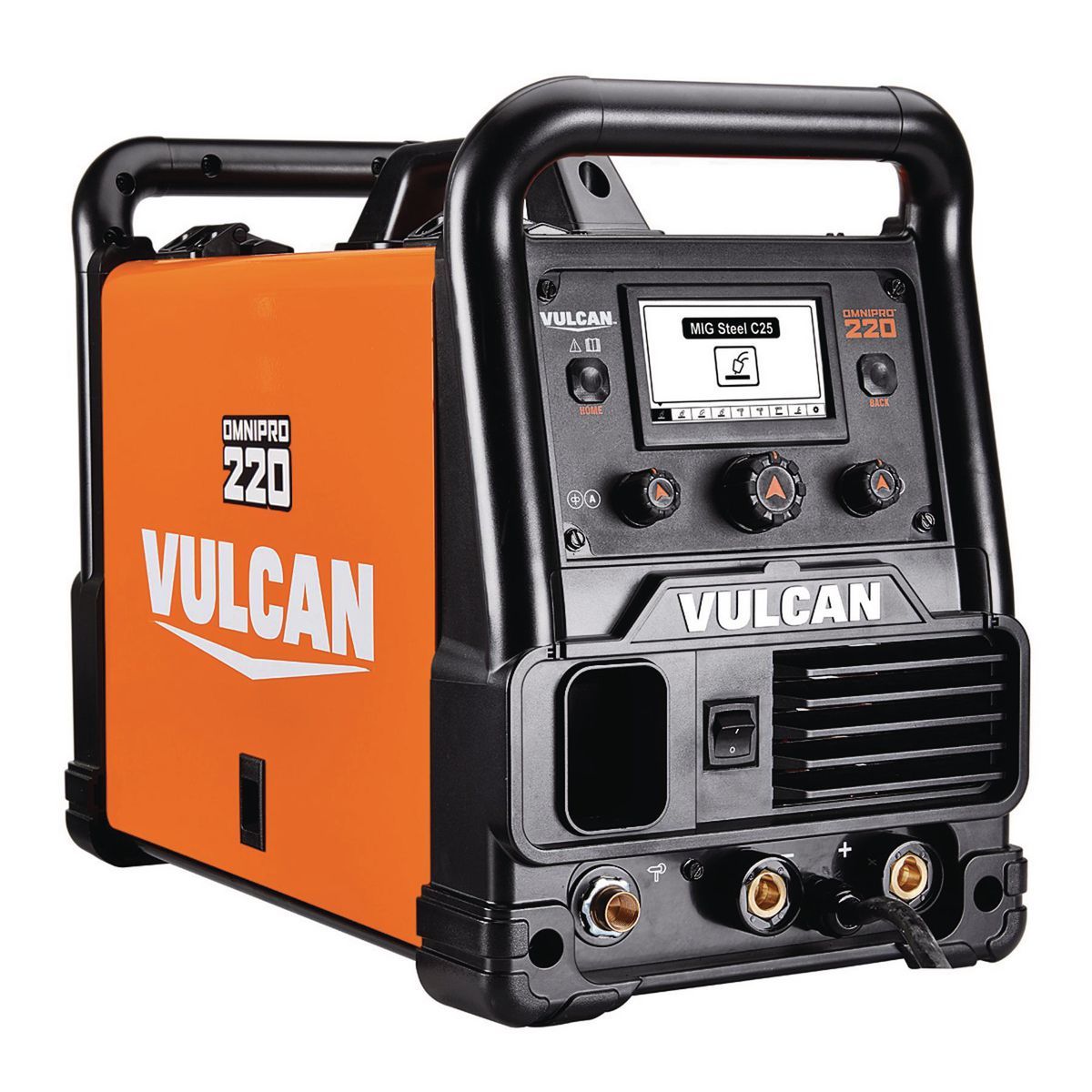

Has anyone actually used the newer HF Vulcan welders (if they even have them in stock)? Next question, has anyone used any of the brightly colored no-name brands on Amazon? I'm looking at the ones that can deliver by Sunday, and from what I'm seeing that essentially excludes name brands. Yes I know it's higher risk and may die quickly (as long as it's not DOA), but that's a risk I have to take to be back up and going immediately.

A cheap inverter won't be as "smooth" of an arc as a transformer machine but it will weld just fine. I would have zero qualms about sticking together shit my life depended on with a HF welder I bought an hour prior. If you can weld worth a shit you will know what's up the second you strike an arc. Some of the fancy pants features may be lacking but if you are really that hard up for a welder it shouldn't matter.

Bump for feedback. My ancient ESAB MIG is annoying me and before i start doing anything other than tacks on the rail I'm really eyeing the Vulcan omnipro 220.Figure its time for a fun bump in this thread. I just needed something to get me by that I’ve been ready to replace at any time. But truth is, thing just fawking works. Definitely run 100% .035” wire these days, it’s the only way if all you do is 3/16” or 1/4”

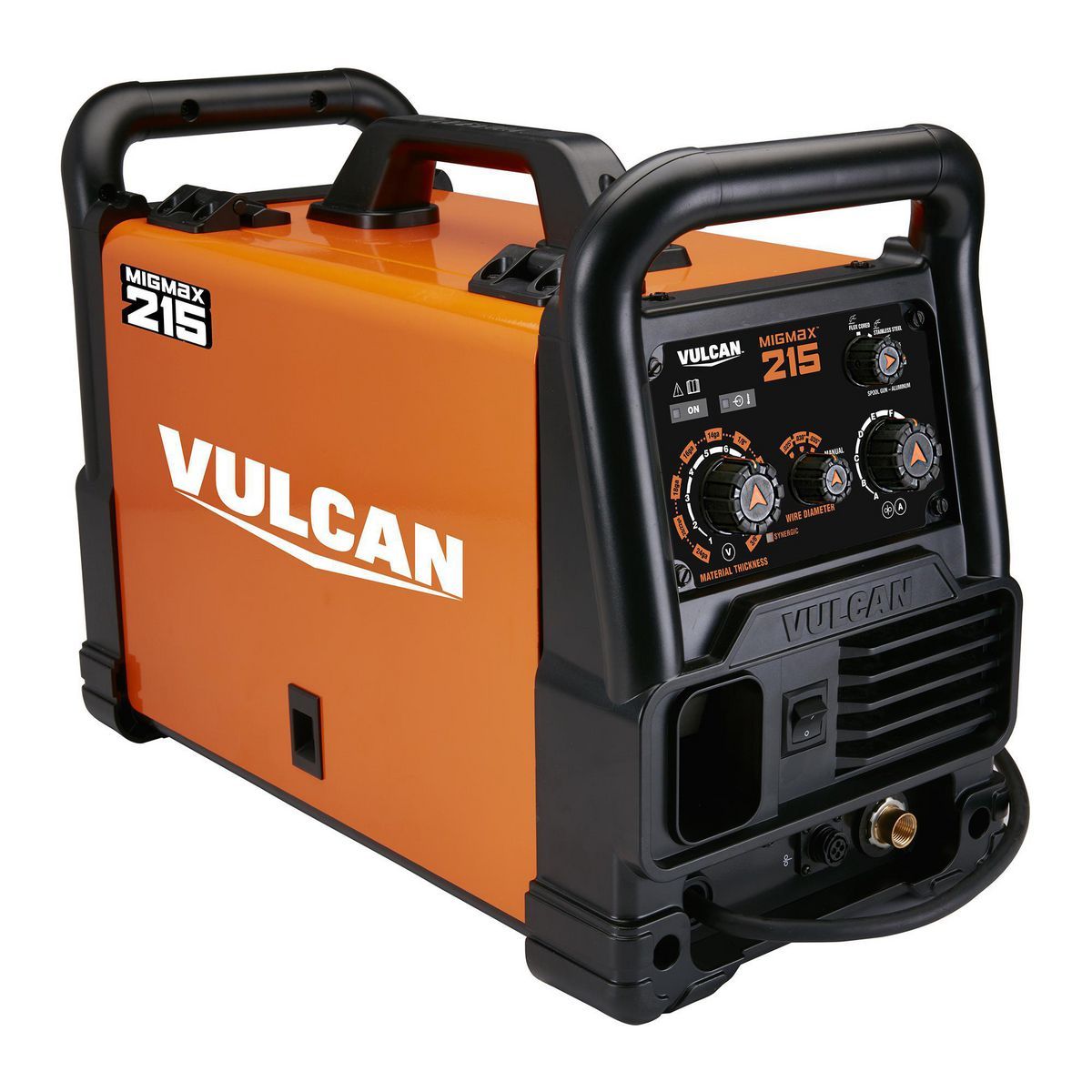

Post 51. He bought this, runs .035 wire, and loves it.Or the migmax. Dont really need the multiprocess as I have my dads Lincoln TIG here.

MIGMax™ 215 Industrial Welder with 120/240V Input

Amazing deals on this Migmax 215 Industrial Mig Welder at Harbor Freight. Quality tools & low prices.www.harborfreight.com

Look up Primeweld. I have their 225 TIG and love it.Bump for feedback. My ancient ESAB MIG is annoying me and before i start doing anything other than tacks on the rail I'm really eyeing the Vulcan omnipro 220.

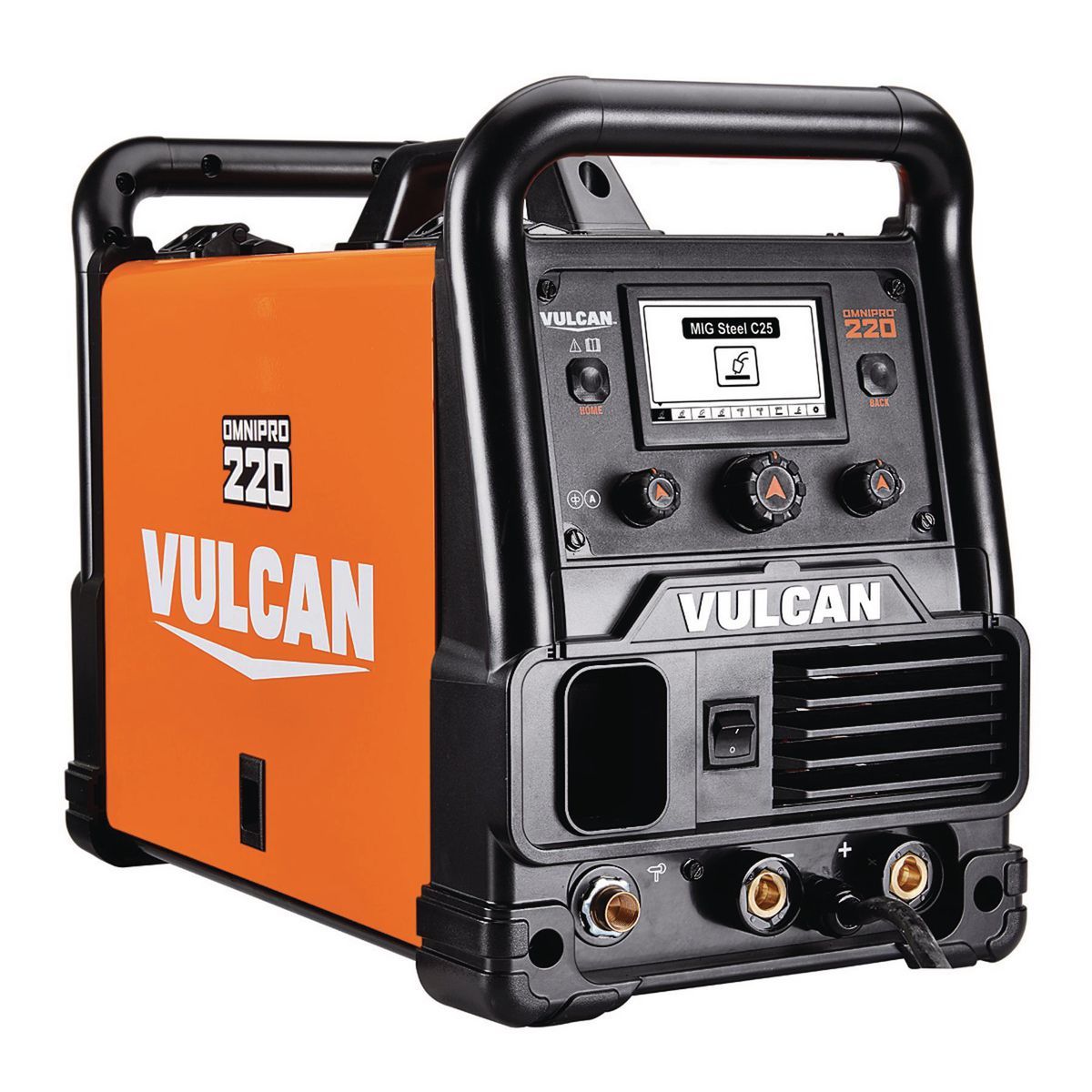

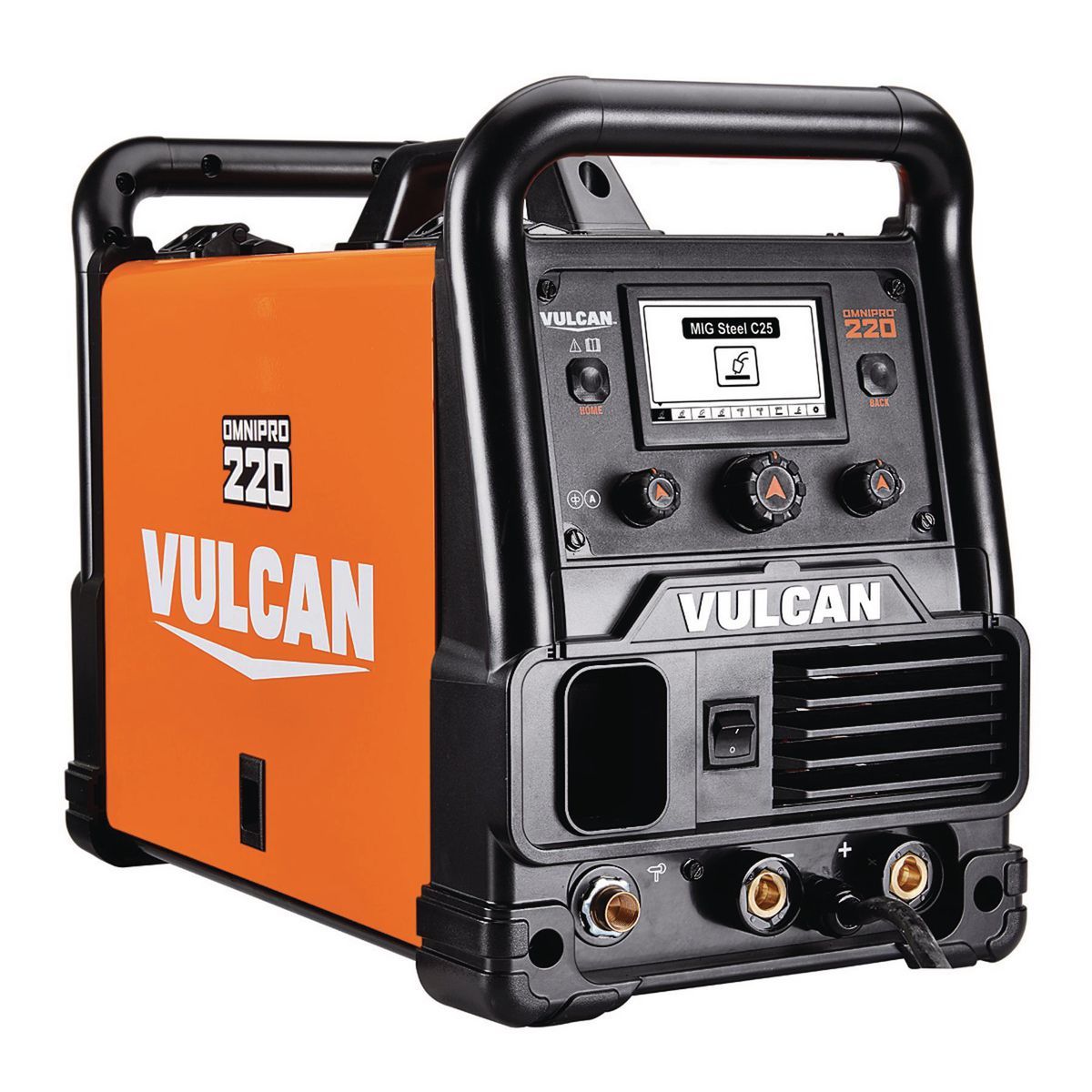

OMNIPRO 220 Industrial Multiprocess Welder with 120/240V Input

Amazing deals on this Omnipro 220 Multiprocess Welder at Harbor Freight. Quality tools & low prices.www.harborfreight.com

Bump for feedback. My ancient ESAB MIG is annoying me and before i start doing anything other than tacks on the rail I'm really eyeing the Vulcan omnipro 220.

OMNIPRO 220 Industrial Multiprocess Welder with 120/240V Input

Amazing deals on this Omnipro 220 Multiprocess Welder at Harbor Freight. Quality tools & low prices.www.harborfreight.com