So, I got a hair across my ass, as I get rid of stuff, to see this again. Pulled it out of storage.

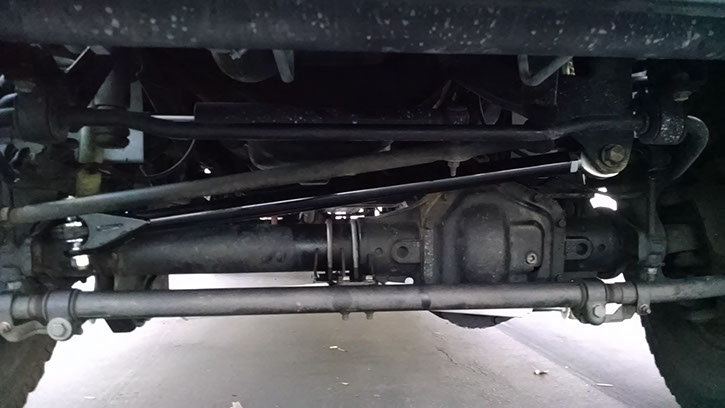

Hate how it looks on the F550 chassis.

I got a C50 frame from John Giffin before he fled black fly country. This frame profile fits the G506 cab better.

The new ladder frame is 34" OD, and the F550 rear axle and springs/hangers would bolt up.

Looks like I could fit F150 rear leaves and shackle into the funky leaf spring hangers that were there. They would be 31.5" spring pin to spring pin, which means the 2004 F550 SD60 (Fat Boy) we cut down would fit. My son says go with leaves and finish cutting down the axle, that

JR4X is sending me tube for . The long side would take a Chevy 60 long side axle, too boot. I was going to stick this axle into my street queen YJ, but it's really not needed.

Or radius arm brackets that fit the 34" OD of this new frame and bolt up the 2011 SD F550 front end (suspension, etc) and I already have bolt on spring and shock buckets. Everything would be stock and mimic my other big tired project, the IH.

Thoughts?