'84 Bronco II

El Chingón

Does anyone know of a vendor for chromoly slip yokes for the center joint of a Dana 35/Dana 44 TTB?

You can get pretty affordable 4340 axle shafts sets for the Dana 35 and Dana 44 TTB through Jeff's Bronco Graveyard now, but no one lists a 4340 slip yoke for them which pretty much defeats the purpose of buying 4340 shafts in the first place. I talked to Solo Motorsports over a year ago and they said they should have one soon, but every time I checked back, they kept telling me "just a little while longer" until I lost interest. I'll probably try calling them again this week.

Yes, I am aware of the Dana 50 center joint swap which is great for guys with Dana 44s, but you still don't have a 4340 inner shaft then. If I can get some 30 spline side gears I might look into that for my Dana 35. I am trying to keep this as cheap/easy and bolt in as possible though and I am not sure about the clearance of a 1350 center joint in a Dana 35 beam.

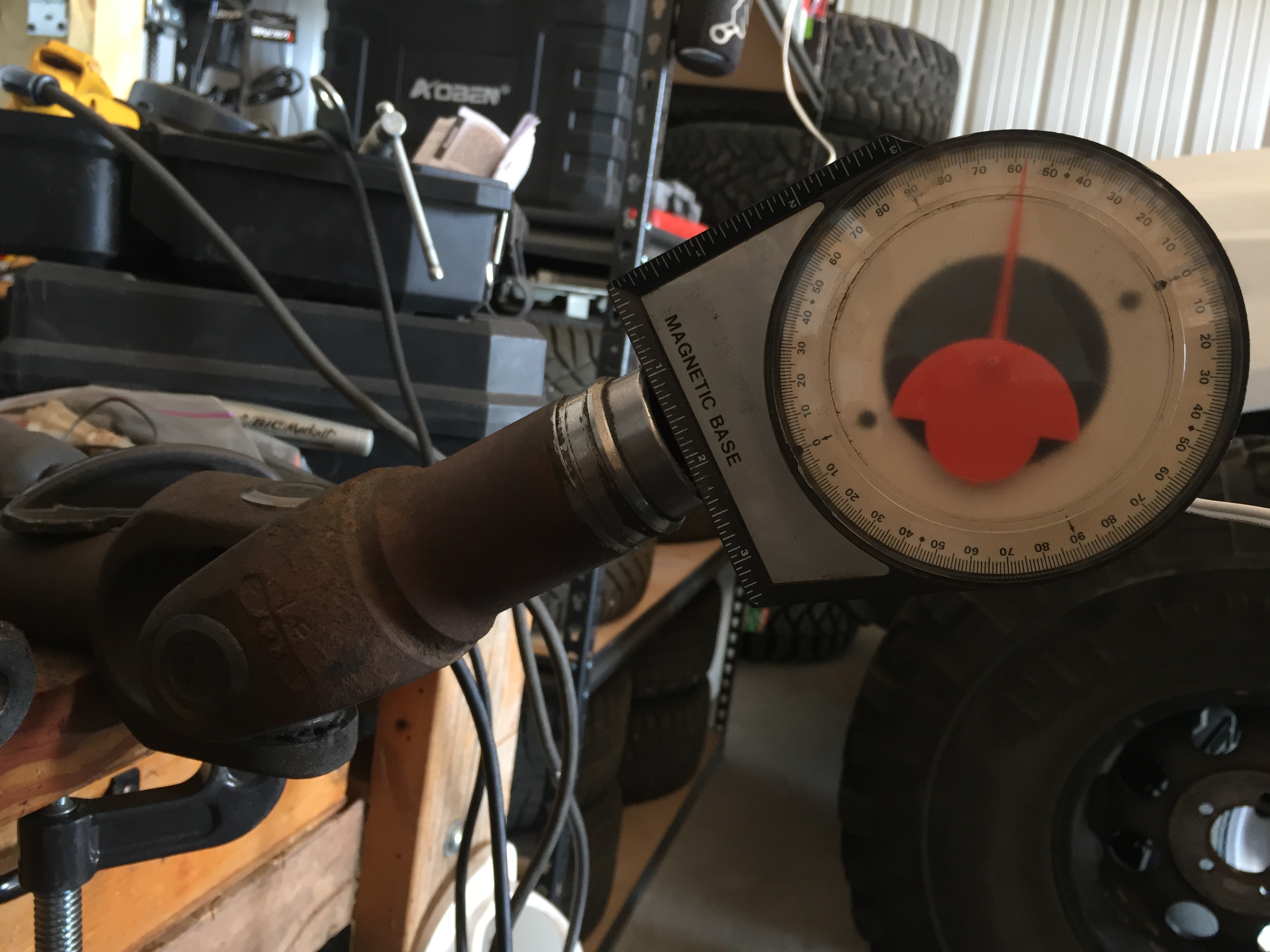

Carnage picture for funsies. Full circle clips and welding most of the U-joint caps in is not enough

You can get pretty affordable 4340 axle shafts sets for the Dana 35 and Dana 44 TTB through Jeff's Bronco Graveyard now, but no one lists a 4340 slip yoke for them which pretty much defeats the purpose of buying 4340 shafts in the first place. I talked to Solo Motorsports over a year ago and they said they should have one soon, but every time I checked back, they kept telling me "just a little while longer" until I lost interest. I'll probably try calling them again this week.

Yes, I am aware of the Dana 50 center joint swap which is great for guys with Dana 44s, but you still don't have a 4340 inner shaft then. If I can get some 30 spline side gears I might look into that for my Dana 35. I am trying to keep this as cheap/easy and bolt in as possible though and I am not sure about the clearance of a 1350 center joint in a Dana 35 beam.

Carnage picture for funsies. Full circle clips and welding most of the U-joint caps in is not enough