Continuing to chip away at this thing on the weekends. Lots of progress done this weekend.

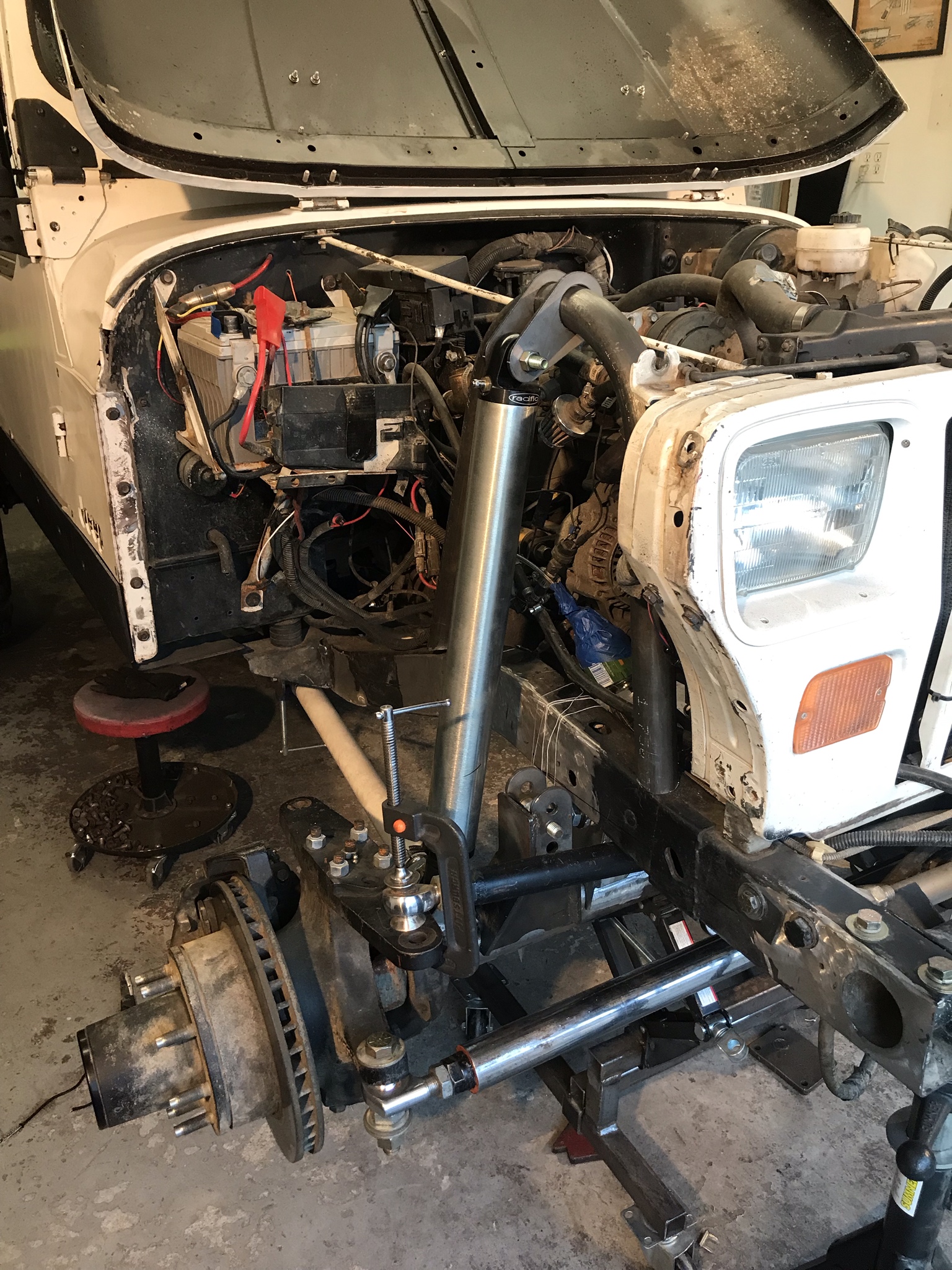

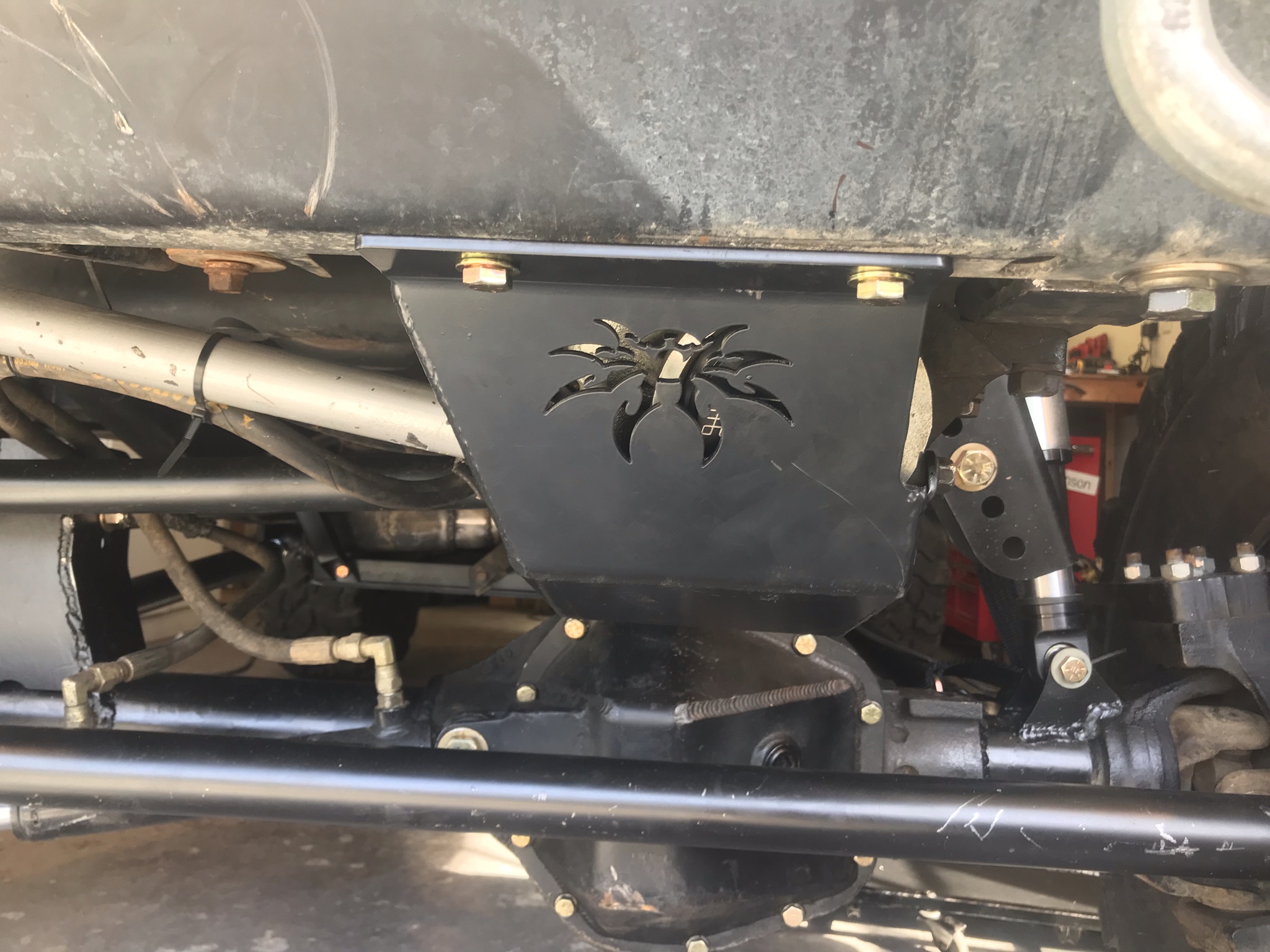

First order of business was to fix the giant hole cutout in my frame to my drag link and pandhard bar mounts. I first plated the bottom then I built some fish plates that mimic the cutout in hopes of regaining some strength. It is built around the shock hoop and fish plated on both sides of the frame. The shock hoop was also fulled welded to the top of the stock frame below all of the plating before I welded up the plating. This whole setup feels extremely strong to me. All of this was done with 3/16" plate.

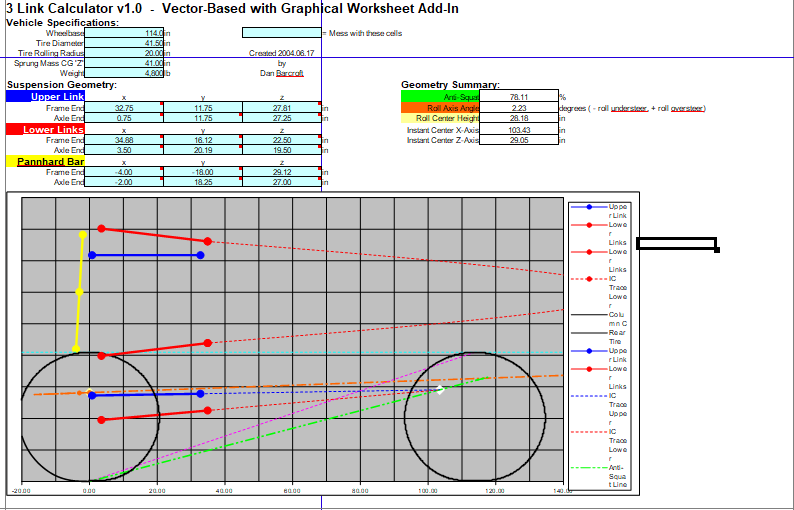

You know how sometimes you have great ideas but they just don't pan out the way you wanted them to. That's basically the story of my bump stops. I had plans of running my bump stops behind the shocks and building the bump pad on top of my lower link mount. After spending half of the day building bump stops, mounts and lower bump pads then mocking everything up I ended up defeated. I tried to run them at the same angle as the shock and have everything jive but while the axle is drooping the shocks kept coming in contact with the bump cans. The picture below is as far back as I can move the mounts and still have the lower bump pad on the link mount. I finally called it quits and will revisit at another time. I think I will just have to have my pad come about 2" off the back of the link mount, which will require some creative reinforcing. I know in the pictures it looks like theres plenty of room but I run out quick.

Here's my attempt

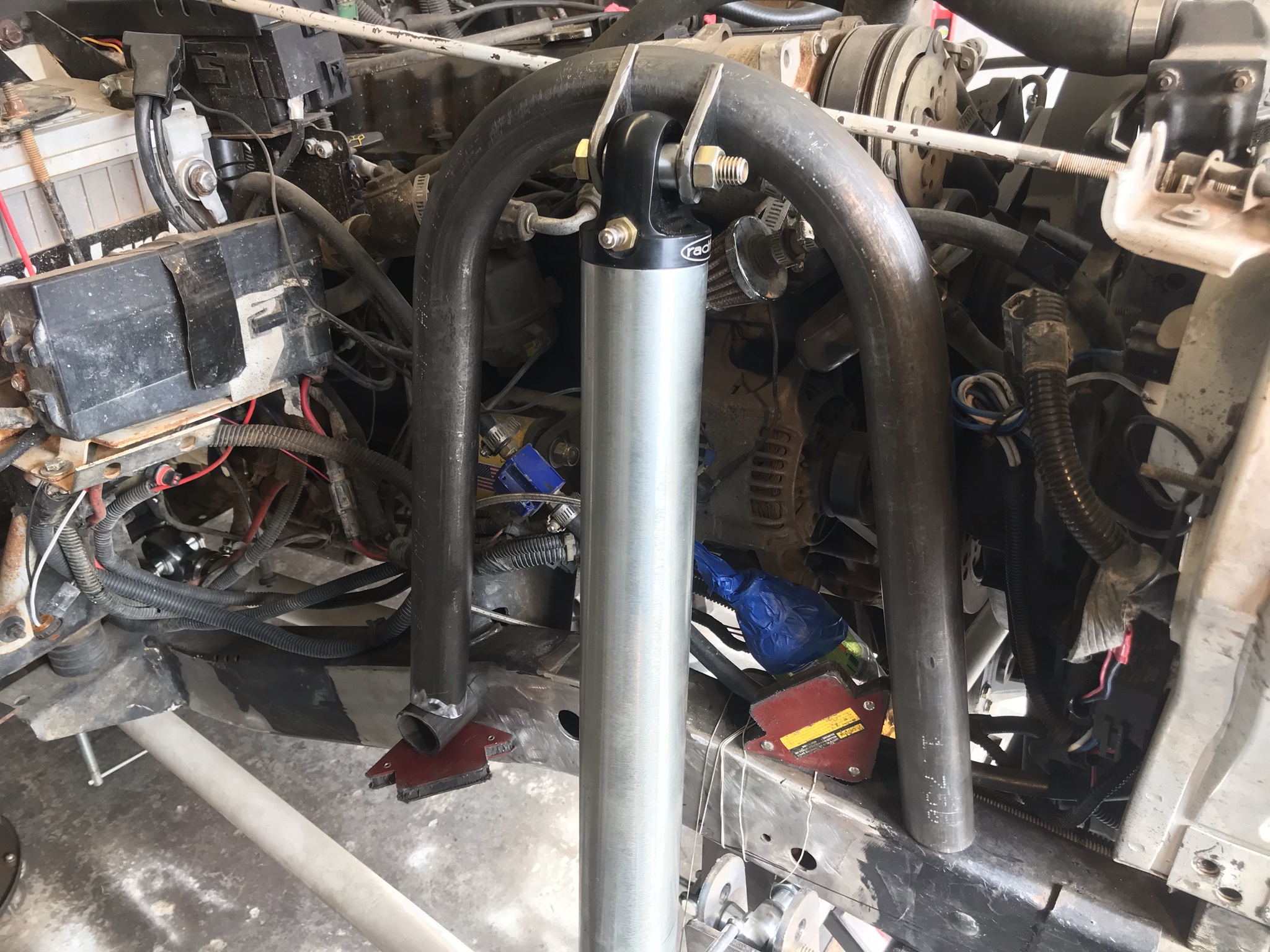

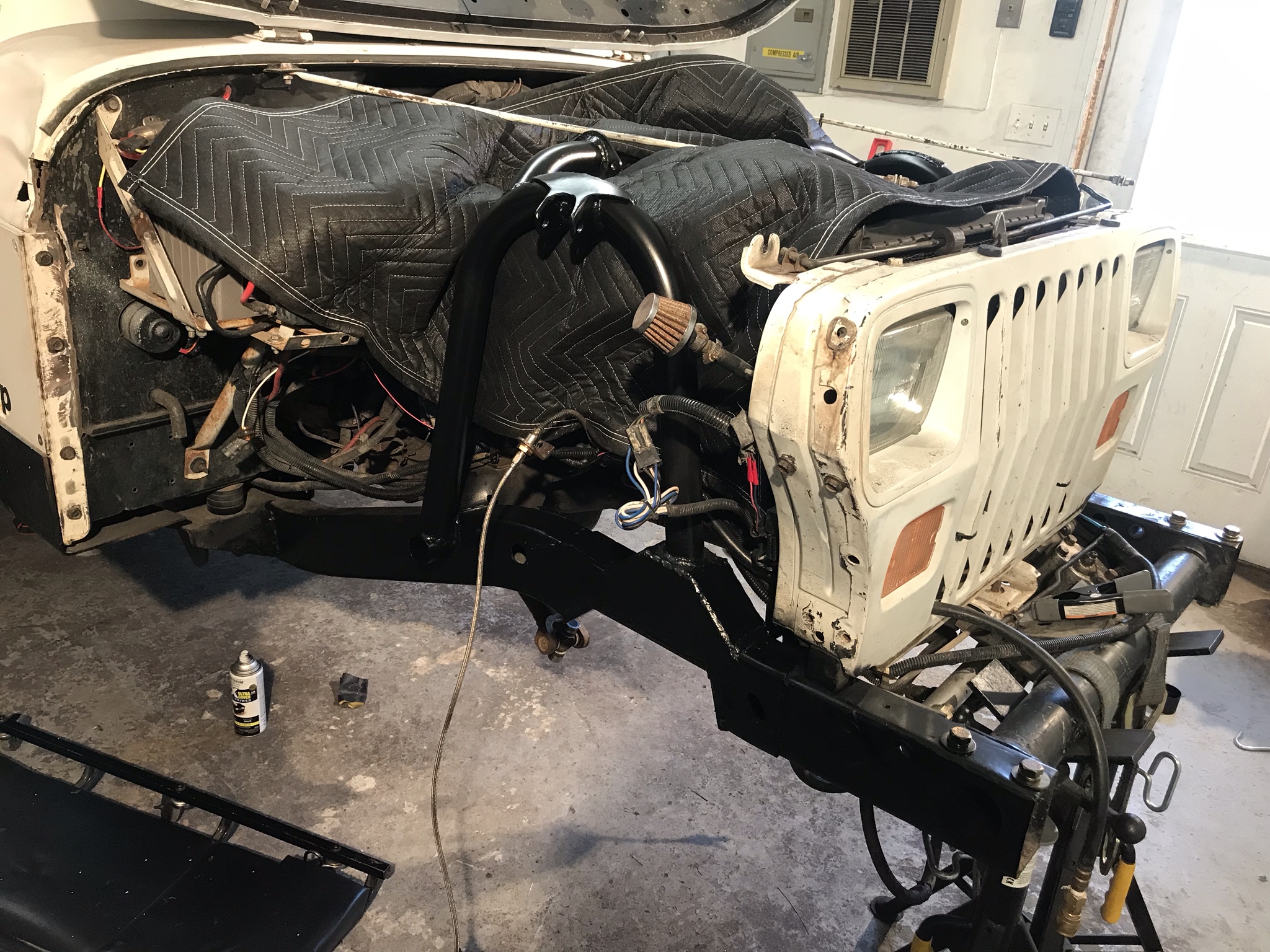

After that I pulled the axle for final welding and started building my shock tower brace and reinforcing my shock tabs on the hoops.

One problem with the new shock hoops and brace is that my Airaid intake tube and filter no longer fits.

Can't fit here

Can't fit under

After a little online searching it looked like a TJ intake tube might work. So I promptly drove by my buddies house and stole the intake tube off his TJ sitting in his driveway while he was at work

This should work

And with a little PVC as an extension it fits perfect. I will need to add a 90 degree elbow to the PCV nipple and drill and insert my vacuum tube going to the charcoal canister but overall I think this will fit my needs. I am going to hop on Ebay when Im done writing this and snag one for myself and return Tyler's.

Now it was time to get everything finish welded and painted.

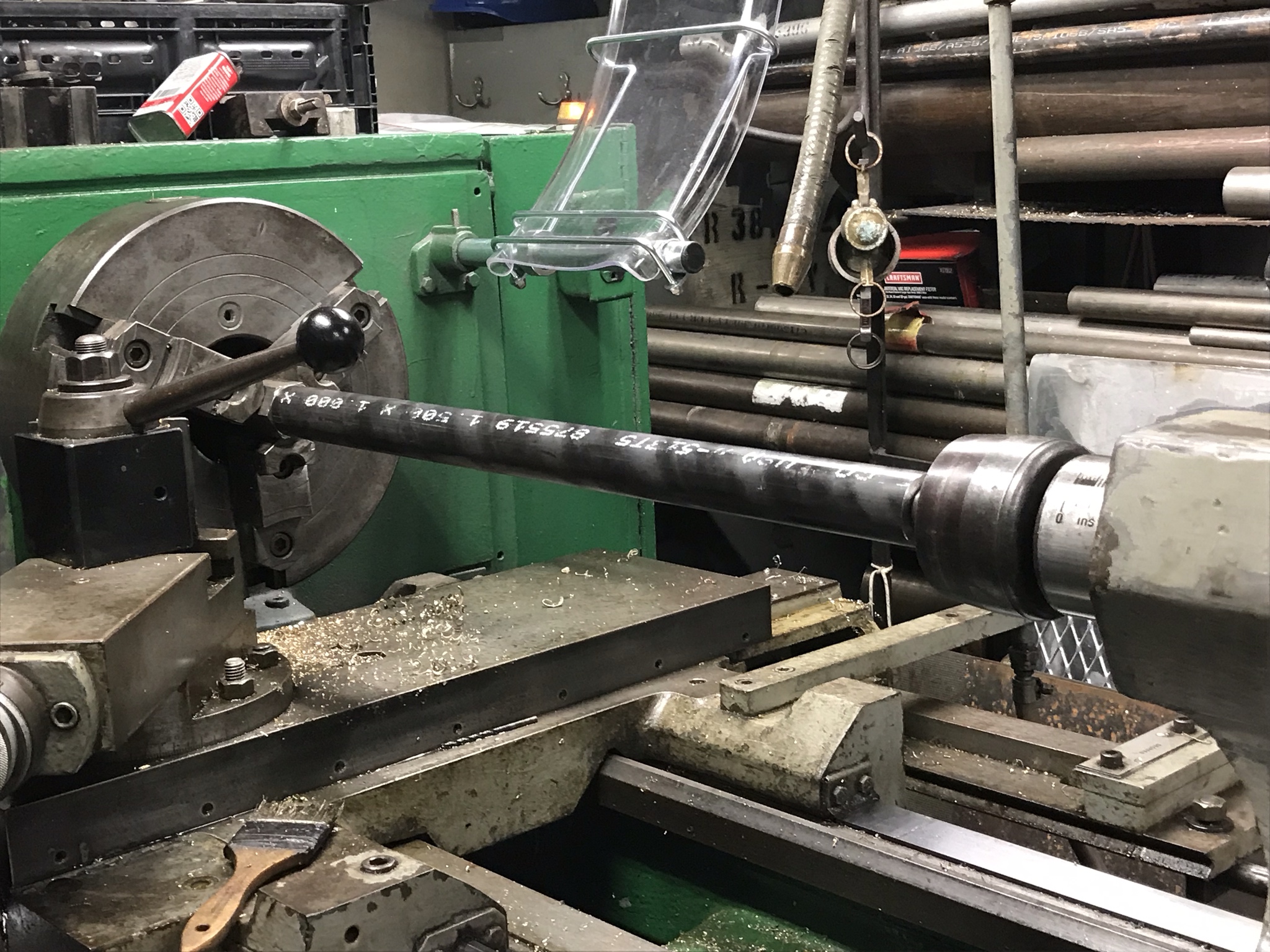

I love having taps in every size I need. I burned in all of my links and track bar in about 20 minutes. Cranked the welder all the way up and burned it in nice and hot without worrying about distorting the threads. Taps really aren't as expensive as everyone says. I have 1.25, 7/8 and 3/4 in both left and right thread for all my links, steering and track bar. I picked up the 1.25 for about $40 a piece on Ebay and the 7/8 were like $25 a piece.

I wanted to see what the difference in weight was between my lower link with the internal sleeve and the upper link which is 1.75x.120. I can tell you my upper link feels like a feather compared to the lower. All of my links are the same length so it's a pretty apple to apple comparison. To get the weight I did what any sensible person would do..... I brought them inside and put them on my wife's bathroom scale

The lower link weighed in at 17.2lbs

The upper link was too light for the scale to measure it.

So I took a before and after of my weight first not holding the link then holding the link. looks to be about 5.4lbs. A little less than 1/3 the weight of my lowers.

And then I finally started painting. You can also see in the backround the reason for the 3 link. All of those leaf springs have been bent during my 4 offroad trips since switching to tons.