'92 Vegas YJ

Well-known member

- Joined

- May 25, 2020

- Member Number

- 1389

- Messages

- 147

figured I'd stop by and give a quick update. I have been chipping away at this thing a little at a time. Its mostly an hour here or an hour there. A lot of time spent taking measurements of things.

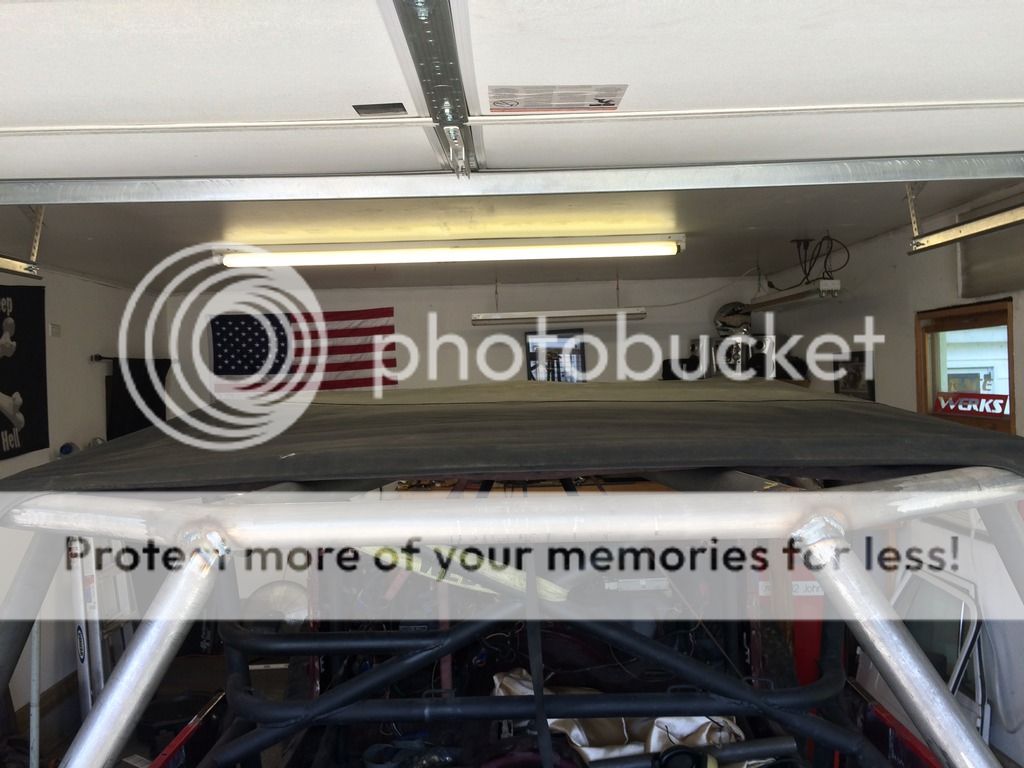

The next step I needed to start was working on my cage. I first added some braces to the middle part of the cage so that when I cut off the rear none of the tube would move on me. After that I chopped off the rear. These pictures really suck but it's all I took at the time.

Then I rolled it out of the garage and the wife and I threw the front half of the cage in it. You get get a pretty good look at the stance in these picture too. The rear suspension is still just tac'd in place with PVC links and some tube holding the frame up.

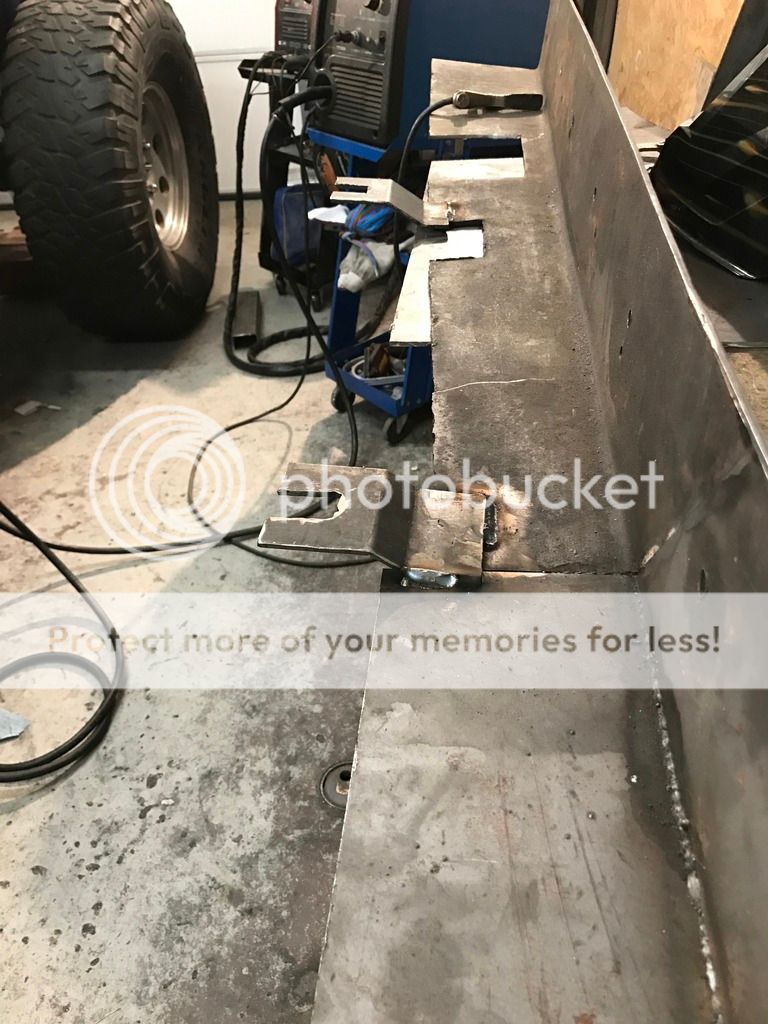

And I've been slowly knocking out the rear pieces throughout the week. Making my internal slugs is what takes the longest. They are 1.5x.250" DOM that I have to shave down to press fit into the main cage. You can really start to see this thing coming together when you see it with the rear bars of the cage sitting in place. I will still be adding a halo to the rear to give more overhead cover for the back seat.

I also got myself a couple other items for the garage to make life easier on myself. The first thing I picked up was a cheap HF benchtop belt/disc sander combo. I didn't want to take up anymore room on my workbench though and I didnt want ANOTHER tool that I'm tripping over in the center of the garage so I made a pretty low profile stand for it. It now sits on the stand up against the wall right next to one of my outlets. Not in the way at all.

This thing has been awesome for tube prep and shaving down my slugs. I thing it'll work pretty good shaping brackets as well. Its not the strongest motor in the world but its working well for what I need it to do right now.

The stand I made out of a spare wheel I had, some of the 3x4x.25" box tube that I made my frame extensions with and some 1/4" diamond plate I had laying around.

The other item I got for the garage has made the last couple days a dream. I picked up a window AC off of CL for about half what they retail for. Ive been working in that garage all week with the doors shut and not sweating AT ALL. Its freaking AMAZING.

Well thats all for now. I will keep plugging away on this Jeep. Hopefully get some good time in this weekend.

The next step I needed to start was working on my cage. I first added some braces to the middle part of the cage so that when I cut off the rear none of the tube would move on me. After that I chopped off the rear. These pictures really suck but it's all I took at the time.

Then I rolled it out of the garage and the wife and I threw the front half of the cage in it. You get get a pretty good look at the stance in these picture too. The rear suspension is still just tac'd in place with PVC links and some tube holding the frame up.

And I've been slowly knocking out the rear pieces throughout the week. Making my internal slugs is what takes the longest. They are 1.5x.250" DOM that I have to shave down to press fit into the main cage. You can really start to see this thing coming together when you see it with the rear bars of the cage sitting in place. I will still be adding a halo to the rear to give more overhead cover for the back seat.

I also got myself a couple other items for the garage to make life easier on myself. The first thing I picked up was a cheap HF benchtop belt/disc sander combo. I didn't want to take up anymore room on my workbench though and I didnt want ANOTHER tool that I'm tripping over in the center of the garage so I made a pretty low profile stand for it. It now sits on the stand up against the wall right next to one of my outlets. Not in the way at all.

This thing has been awesome for tube prep and shaving down my slugs. I thing it'll work pretty good shaping brackets as well. Its not the strongest motor in the world but its working well for what I need it to do right now.

The stand I made out of a spare wheel I had, some of the 3x4x.25" box tube that I made my frame extensions with and some 1/4" diamond plate I had laying around.

The other item I got for the garage has made the last couple days a dream. I picked up a window AC off of CL for about half what they retail for. Ive been working in that garage all week with the doors shut and not sweating AT ALL. Its freaking AMAZING.

Well thats all for now. I will keep plugging away on this Jeep. Hopefully get some good time in this weekend.