Pretaco

Yellow Skull

- Joined

- Feb 1, 2023

- Member Number

- 6016

- Messages

- 7

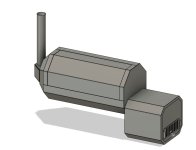

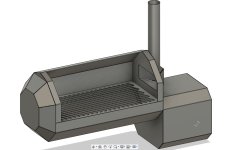

I want to build a small backyard offset smoker for myself and also as a prototype for sale.

Here is what I have so far:

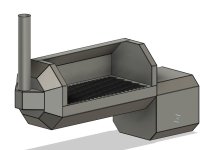

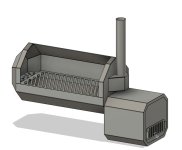

20x40 main grill surface, expanded metal with slide out. Will add another slide out surface above main grill.

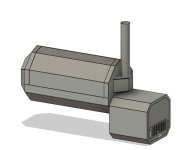

53 gallon sized smoke box, 22 gal firebox, 4" stack (24" tall).

1" insulation around firebox.

10 gauge construction for whole unit. Stack will be 16ga.

Obviously I have to add the hinges, handles, counterweight, shelves, frame and wheels.

Anybody got one about this size, what do you like / what would you change?

Here is what I have so far:

20x40 main grill surface, expanded metal with slide out. Will add another slide out surface above main grill.

53 gallon sized smoke box, 22 gal firebox, 4" stack (24" tall).

1" insulation around firebox.

10 gauge construction for whole unit. Stack will be 16ga.

Obviously I have to add the hinges, handles, counterweight, shelves, frame and wheels.

Anybody got one about this size, what do you like / what would you change?