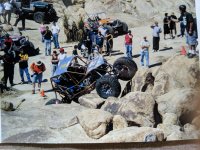

upside-down

Member

Np241c .

I cut down the tail cone , bought a yoke , and performed hack and tappage.

I was able to chuck the shortened tail on my wood lathe to make the seal fit inside .

I cut down the tail cone , bought a yoke , and performed hack and tappage.

I was able to chuck the shortened tail on my wood lathe to make the seal fit inside .