Not a sawzall to the frame. Did zip disc on the frame. Sawzall on the body though. Mentioned it in my build thread. Saw blades and drill bits won’t touch whatever the roll cage and windshield frame are made of. Only abrasives will cut it. The frame is 3/16” thick and in some places it’s double layered 3/16” thick.JR4X have you taken a sawzall to the frame yet?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Bronco reports

- Thread starter Poke

- Start date

Just scrolled up and saw the context to the question. Myself and Atteberry didn’t use the factory upper link placement because the upper links are maybe 12” inches long. Loren and Vaughn’s uses the factory upper pivot point thiugh

Jwredneck

Red Skull Member

Mitch at Wildhorses is having upper link mount issues too.

CDA 455 II

ANFAQUE2

Interesting.🤔

He's the one who I first heard of having it.

popo_patty is my buddy who brought it to my attention.

popo_patty is my buddy who brought it to my attention.

Talon2006

Yellow Skull

- Joined

- May 19, 2020

- Member Number

- 282

- Messages

- 426

I just sent Mitch a message, and Bronc Buster as well about working towards coming up with a bracing solution.

Not sure how practical it would be if they have fixed this already, but mine is a 2020 iirc so it might have the issue as well.

Not sure how practical it would be if they have fixed this already, but mine is a 2020 iirc so it might have the issue as well.

NorCalJalopy

Well-known member

- Joined

- Aug 27, 2022

- Member Number

- 5491

- Messages

- 241

Bronc Buster? Why support a guy that thinks it’s ok to ruin iconic trails and not fix it? Claims he will fix it next year?I just sent Mitch a message, and Bronc Buster as well about working towards coming up with a bracing solution.

Not sure how practical it would be if they have fixed this already, but mine is a 2020 iirc so it might have the issue as well.

Back to the top….

Talon2006

Yellow Skull

- Joined

- May 19, 2020

- Member Number

- 282

- Messages

- 426

What trail did he destroy?Bronc Buster? Why support a guy that thinks it’s ok to ruin iconic trails and not fix it? Claims he will fix it next year?

Back to the top….

popo_patty

Active member

- Joined

- Sep 16, 2023

- Member Number

- 6906

- Messages

- 38

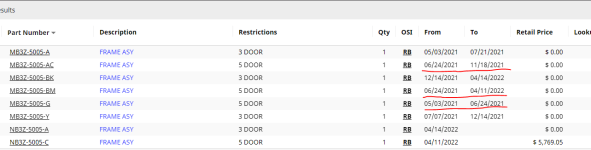

I have a fab guy also working on a fix. I’ve documented multiple modified broncos and 2 stock broncos with the issue now. All are occurring to 21 Broncos. It seems a small batch of frames (estimating several hundred) were made in early 2021 with the open design bracket (pictured). These were randomly added to 21 Broncos. Then the design changed and all Broncos since have gotten the boxed brackets with no known issues. Bottom line is that if you’re a 21 with the open design. Keep an eye on it. If you wheel hard or are modified you’re likely to crack. Bronco6g has an extensive thread on the topic that is pages long. Too much to go over. Essentially in 21, it was completely random if you got the open, weaker design or stronger, boxed design. Luck of the draw based on the feedback and research done so far. The early run of frames were scattered throughout the lineup.I just sent Mitch a message, and Bronc Buster as well about working towards coming up with a bracing solution.

Not sure how practical it would be if they have fixed this already, but mine is a 2020 iirc so it might have the issue as well.

Attachments

-

F3333C1C-A723-4D7B-8A4F-FEBD058E5A7F.jpeg81.9 KB · Views: 39

F3333C1C-A723-4D7B-8A4F-FEBD058E5A7F.jpeg81.9 KB · Views: 39 -

0C5E182E-AC86-440F-A9AD-FAA98051A6A0.png15.5 KB · Views: 39

0C5E182E-AC86-440F-A9AD-FAA98051A6A0.png15.5 KB · Views: 39 -

456DAF67-7F7B-4809-91B4-FA274A8462B5.jpeg1.6 MB · Views: 39

456DAF67-7F7B-4809-91B4-FA274A8462B5.jpeg1.6 MB · Views: 39 -

A51916CC-CA83-4816-A8DB-BF8A068503C6.jpeg517.9 KB · Views: 39

A51916CC-CA83-4816-A8DB-BF8A068503C6.jpeg517.9 KB · Views: 39 -

702A2574-1D28-4D53-AA6D-130E07319B9C.jpeg1.7 MB · Views: 41

702A2574-1D28-4D53-AA6D-130E07319B9C.jpeg1.7 MB · Views: 41 -

B8FD9633-C588-483C-B2C1-90078D93463E.png1.1 MB · Views: 37

B8FD9633-C588-483C-B2C1-90078D93463E.png1.1 MB · Views: 37 -

AC383560-595B-47A2-933B-A61C9B0C046E.jpeg1 MB · Views: 42

AC383560-595B-47A2-933B-A61C9B0C046E.jpeg1 MB · Views: 42 -

CB1A5368-BBCA-425B-BA09-B50D9B1E87CB.jpeg3.5 MB · Views: 43

CB1A5368-BBCA-425B-BA09-B50D9B1E87CB.jpeg3.5 MB · Views: 43 -

51A457DA-9478-4ACD-AF8D-6930F39FB955.jpeg1.6 MB · Views: 43

51A457DA-9478-4ACD-AF8D-6930F39FB955.jpeg1.6 MB · Views: 43

NorCalJalopy

Well-known member

- Joined

- Aug 27, 2022

- Member Number

- 5491

- Messages

- 241

Rubicon, Mitch was broke down and bb decided it was a grand idea to winch a rock out of the way and didn’t put it back. Called him out numerous times and he came back with the response “I’ll put it back next year.”What trail did he destroy?

Tech Tim

Your AD Here....

Forkin' Bronco drivers....

Jackie Treehorn

Well-known member

- Joined

- May 19, 2020

- Member Number

- 259

- Messages

- 1,006

Took that hit like a champ.Forkin' Bronco drivers....

Forkin' Bronco drivers....

either texting or counting the ducks on the dash.

45acp

naw man

If it was night and you were on a motorcycle, you could see the rectangular glow coming from the steering wheel.either texting or counting the ducks on the dash.

Brad

Jackass

Haven’t looked at the other post in this thread. Just came here to post this

What's the other end of that butt plug look like?Haven’t looked at the other post in this thread. Just came here to post this

CDA 455 II

ANFAQUE2

Interesting;Haven’t looked at the other post in this thread. Just came here to post this

It's on same longitude as I am but 8° latitude South of me.

I’ll get pictures soon. This is the second time I’ve had issues with that particular area. Have had issues with the diff side of the mount before. Fixed that and now tore the bracket off the frame.

I’ll get pictures soon. This is the second time I’ve had issues with that particular area. Have had issues with the diff side of the mount before. Fixed that and now tore the bracket off the frame.

Do you think torque from the portal reduction working in reverse when bumping a ledge or similar situation is tearing the brackets off or something else?

I do think that. When being powered the portals are a gear reduction and take strain off the diff. When being spun by the tires it increases the speed and force on the diff. Something about the portals makes it where when you do a panic brake coming into a corner or a whoop is really hard on the diff.Do you think torque from the portal reduction working in reverse when bumping a ledge or similar situation is tearing the brackets off or something else?

I can feel it in my feet. In Montana the first time it broke the factory hardware holding the pinion support. I was coming into a corner too hot so I got on the brakes as hard as I could. Both felt and heard the snap. This time, coming into big whoops way too hot. Did a nose dive hard on the brakes, felt and heard the snap. Atteberry is having the same issue but theirs breaks the R&P.

arse_sidewards

Red Skull Member

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,556

Imagine if the drive shaft going out the pinion was fixed and the axle coming out of the diff spun. The housing would have to spin to let the axle spin.I do think that. When being powered the portals are a gear reduction and take strain off the diff. When being spun by the tires it increases the speed and force on the diff. Something about the portals makes it where when you do a panic brake coming into a corner or a whoop is really hard on the diff.

Because the whole rest of the upstream drive-train can't change speed instantly there's some force like this being applied to the diff when you stomp the brakes or hit a ledge.

The speed increase from the portal ratio is trying to make the drivetrain change speed faster for a given wheel speed change so the housing is getting hit harder.

Is the diff bushing mounted? Can you switch to a harder rubber or a bigger bushing so that the force doesn't blow right through it?

It is bushed and has a dog bone 🦴 like a lower strut. On the V6 broncos you can’t get the diff in and out without taking this thing off. So the fun havers have had problems breaking the bolts after assembly. On my little 4 cylinder I don’t have to unbolt that to get it in or out. But it’s broken the bolts that hold the dog bone and the mount the bone is bolted to. First two pics are a fun haver diff from a couple years ago. The frame pic if you zoom in you can see the cradle diff mount when it was still new.Imagine if the drive shaft going out the pinion was fixed and the axle coming out of the diff spun. The housing would have to spin to let the axle spin.

Because the whole rest of the upstream drive-train can't change speed instantly there's some force like this being applied to the diff when you stomp the brakes or hit a ledge.

The speed increase from the portal ratio is trying to make the drivetrain change speed faster for a given wheel speed change so the housing is getting hit harder.

Is the diff bushing mounted? Can you switch to a harder rubber or a bigger bushing so that the force doesn't blow right through it?

I wonder if solid mounting it would be better? That way the diff can't get a run at trying to snap the bolts.

Imagine if the drive shaft going out the pinion was fixed and the axle coming out of the diff spun. The housing would have to spin to let the axle spin.

Because the whole rest of the upstream drive-train can't change speed instantly there's some force like this being applied to the diff when you stomp the brakes or hit a ledge.

The speed increase from the portal ratio is trying to make the drivetrain change speed faster for a given wheel speed change so the housing is getting hit harder.

So my brother and I are disagreeing slightly on this. Brother thinks it’s just breaking from use and that slamming on the brakes has nothing to do with it because the brakes are outboard of the portals.

But he’s not raced it yet and I swear I can feel something weird in the front end when I jam on the binders. It makes the transfer case whine when I slam on the brakes but it doesn’t whine when I’m on the gas. Think it’s possible having portals in the front and not in the rear does something mechanically mismatched when I lock up the brakes?

rockmup

El Hefe

That "Shouldn't" matter.

arse_sidewards

Red Skull Member

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,556

Well you have a lot less torque with the skinny pedal than you do with the wide one....But he’s not raced it yet and I swear I can feel something weird in the front end when I jam on the binders. It makes the transfer case whine when I slam on the brakes but it doesn’t whine when I’m on the gas.

So long as there's the same amount of total gear reduction between your brake pad and the pinion yoke I don't think this can be the case.Think it’s possible having portals in the front and not in the rear does something mechanically mismatched when I lock up the brakes?

Which, bringing this back around, makes me think that the effect of the portals on the drive shaft and such is no more than what an equivalent ring and pinion would get you. So in light of that I want to reconsider my comment.

The drive shaft and transfer case can't tell the difference between a 10:1 ring and pinion vs a 5:1 with some 2:1 portals or planetary ends.

It also can't tell the difference between 10:1 at one end and 5:1 X 2:1 at the other.

But that's theory. You're breaking shit in reality.

Someone smarter than me needs to think about the gearbox mounting forces at play here. You've got two separate gearboxes up front and I think that's making it more complex than it would be if you had a portal solid axle because the forces that keep them from spinning relative to each other have to go through the mounts and the suspension and whatnot vs straight down a tube.

My gut says that since this is an issue of speed change and inertia in the rest of the rotating mass of the drivetrain.

Can you get an Oshkosh sponsorship? They can probably have the relevant experience to help you sort it out.

arse_sidewards

Red Skull Member

- Joined

- May 19, 2020

- Member Number

- 71

- Messages

- 8,556

Also, isn't this exactly the kind of thing your OEM rep should be helping with?

If it's failing when you race it's going to fail when other people bolt portals on and floor the brake pedal the street where they will have far more traction available to break shit with.

If it's failing when you race it's going to fail when other people bolt portals on and floor the brake pedal the street where they will have far more traction available to break shit with.

Treefrog

Book Wheeler

It may be an issue of 10:1 at one end and 5:1x2.01:1. The diff may not be designed for the bindingThe drive shaft and transfer case can't tell the difference between a 10:1 ring and pinion vs a 5:1 with some 2:1 portals or planetary ends.

It also can't tell the difference between 10:1 at one end and 5:1 X 2:1 at the other.