You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

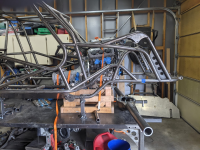

Moon Patrol Buggy Build

- Thread starter YeeP

- Start date

YeeP

Red Skull Member

Ok thank you for the suggestion. I'm at a point right now where I am building the front suspension. I still have months before I have to deal with this, so for now I am going to catalog your contact suggestion. That way when I start dealing with it, I'll have a new option.Hardwired performance comes to mind as a starting point.

Also going to start searching some desert off road forums for builds with this engine.

Really appreciate the input.

YeeP

Red Skull Member

Cool. I reached out to them on Instagram just now. Just to see what kind of work they would be interested in with my scenario.No problem.

I could suggest other people, but they deal more into high end race builds and I'm not sure they would be the right match for you.

Hardwire might already be a lil spendy.

Honestly, if I can find the right schematics, and use my existing harness to fill in the blanks. Conceivably, I could go solo on it.

Iv'e been posting on Honda Odyssey forums asking wiring specific questions with limited success. Seems like a lot of those people aren't into modifying their harness..

YeeP

Red Skull Member

In an effort to make this as chronologically accurate as I can, I have to break theme to include a couple things.

Oil Pan Baffle

I forgot to mention that Marked sells a "oil pan baffle kit" for the oil pan. It ended up being two strips of aluminum that you form by hand. Not terrible I suppose and who am I to judge what someone has figured out what works? I suppose Im paying for the R&D in this scenario. Here they are with some forming putty holding them in place. No instructions, so I just looked at pictures, but I did figure out later that I believe that cut out I have centered on the bottom of them is actually to give room for the windage tray.... oops I thought it might be to not over restrict oil flow.

At the time, the only guy that was willing to weld it for me tried to help a brother out and use some strips of aluminum because he thought these looked weak, without asking me. So the current state, I do not have that extra space below it. Some time was spent grinding the top of the "new" baffle down to get the pan back on the engine.

Just to remind anyone reading this, this engine is a front sump.

TH350

Long winded description of finding trans builder between the lines, skip it if you don't care.

So my CJ was rockin an AMC TH400. Which I built myself when I put it in. I'm no transmission specialist but at the time I had the ASE Certification, and they guy that worked in the bay next to me at the shop I was in was the shop transmission guy. He watched over my shoulder while I built it to make sure it was good. It worked fine except the parking pawl never really held well.

Either way, I decided I wasn't going to build this one on my own. For one, I wanted to be able to use the knowledge that someone with more experience than myself had. Second reason was time. I would rather get to the 'fun' stuff in the project.

YeeP Rant

I will always try to avoid dirtying someone's name, but there are times when I just have to call out stuff that pisses me off. Automotive businesses seem to be one of the worst offenders in this scenario. I don't have all the answers here, and I am sympathetic to these guys because I used to do it for a living. If you own a shop, and you want to do business, DON'T BE A DICK to people on the phone! I'm sure you get tired of people calling you that don't spend money. Take a breath and speak with them.

There is a guy that is in my local circle of wheelers that is well known out here for his bad ass fab skills (started his own fab shop, worked at several buggy building shops). He has a good rep for that. I asked him who he uses for his transmission building and he gave me a contact that has built several of his personal rig trannies. I don't need some super maxed out TH350 for a Honda V6 (or maybe this Honda V6), but there were a couple things I was concerned about and wanted to make sure I was on the same page as the builder. This fuckin guy could have cared less about one word I said. He was audibly annoyed with me on the phone. I had several friends back him up later with comments like "he's just like that", "do you want a good tranny or a guy to chat with". Sorry man, thats not how it works for me. I'll find someone else. He also was ready to tell me to pound sand when I told him I already had a converter. I know, he doesn't want to have to deal with issues possibly caused by me choosing a bad converter down the road. Still, how about you ask me how I choose it. Ask me what the stall speed is, how did I determine that would work with the engine...BTW, this guy quoted me 700 for standard rebuild including installing a reverse manual valve body, not a bad price honestly.

So after the enjoyable experience above, I decided to call my old buddy who helped me with the TH400, maybe he would work with me, or I could pay him. He told me that the shop he is in no longer builds transmissions in house and they outsource everything. He is however into drag cars, and gave me the number of his guy. The guy quoted me $700 also, he did ask me questions about the converter, and made an effort to understand what I was trying to build. Side note: I have have since sent two friends that had their daily drivers tranny take a digger to him. Don't be a dick.

Why TH350? I wanted 3 gears, and the least parasitic hp drain I could get without a super elaborate modified tranny. Th350 can easily hold up behind this engine, so I wouldn't have to do some crazy mods, and I was able to find a 'K-case' so I had that added insurance. Here is what she looked like when complete (The builder sent me this pic cause he knew I was excited about it. Cool guy):

List of additions to this tranny:

"Stef’s Fabricated Aluminum Deep Pan -“Super Filter” w/ Rear Pick-up for Improved Oil Control "

This is meant for drag racing, but a rear mounted pickup sounded like a step in the right direction. I called them and they pointed me toward how to get the pan and pickup. Done and done.

Some stuff I should have done before taking it to the builder that I still have to address:

Upcoming plans for transmission:

Oil Pan Baffle

I forgot to mention that Marked sells a "oil pan baffle kit" for the oil pan. It ended up being two strips of aluminum that you form by hand. Not terrible I suppose and who am I to judge what someone has figured out what works? I suppose Im paying for the R&D in this scenario. Here they are with some forming putty holding them in place. No instructions, so I just looked at pictures, but I did figure out later that I believe that cut out I have centered on the bottom of them is actually to give room for the windage tray.... oops I thought it might be to not over restrict oil flow.

At the time, the only guy that was willing to weld it for me tried to help a brother out and use some strips of aluminum because he thought these looked weak, without asking me. So the current state, I do not have that extra space below it. Some time was spent grinding the top of the "new" baffle down to get the pan back on the engine.

Just to remind anyone reading this, this engine is a front sump.

TH350

Long winded description of finding trans builder between the lines, skip it if you don't care.

So my CJ was rockin an AMC TH400. Which I built myself when I put it in. I'm no transmission specialist but at the time I had the ASE Certification, and they guy that worked in the bay next to me at the shop I was in was the shop transmission guy. He watched over my shoulder while I built it to make sure it was good. It worked fine except the parking pawl never really held well.

Either way, I decided I wasn't going to build this one on my own. For one, I wanted to be able to use the knowledge that someone with more experience than myself had. Second reason was time. I would rather get to the 'fun' stuff in the project.

YeeP Rant

I will always try to avoid dirtying someone's name, but there are times when I just have to call out stuff that pisses me off. Automotive businesses seem to be one of the worst offenders in this scenario. I don't have all the answers here, and I am sympathetic to these guys because I used to do it for a living. If you own a shop, and you want to do business, DON'T BE A DICK to people on the phone! I'm sure you get tired of people calling you that don't spend money. Take a breath and speak with them.

There is a guy that is in my local circle of wheelers that is well known out here for his bad ass fab skills (started his own fab shop, worked at several buggy building shops). He has a good rep for that. I asked him who he uses for his transmission building and he gave me a contact that has built several of his personal rig trannies. I don't need some super maxed out TH350 for a Honda V6 (or maybe this Honda V6), but there were a couple things I was concerned about and wanted to make sure I was on the same page as the builder. This fuckin guy could have cared less about one word I said. He was audibly annoyed with me on the phone. I had several friends back him up later with comments like "he's just like that", "do you want a good tranny or a guy to chat with". Sorry man, thats not how it works for me. I'll find someone else. He also was ready to tell me to pound sand when I told him I already had a converter. I know, he doesn't want to have to deal with issues possibly caused by me choosing a bad converter down the road. Still, how about you ask me how I choose it. Ask me what the stall speed is, how did I determine that would work with the engine...BTW, this guy quoted me 700 for standard rebuild including installing a reverse manual valve body, not a bad price honestly.

So after the enjoyable experience above, I decided to call my old buddy who helped me with the TH400, maybe he would work with me, or I could pay him. He told me that the shop he is in no longer builds transmissions in house and they outsource everything. He is however into drag cars, and gave me the number of his guy. The guy quoted me $700 also, he did ask me questions about the converter, and made an effort to understand what I was trying to build. Side note: I have have since sent two friends that had their daily drivers tranny take a digger to him. Don't be a dick.

Why TH350? I wanted 3 gears, and the least parasitic hp drain I could get without a super elaborate modified tranny. Th350 can easily hold up behind this engine, so I wouldn't have to do some crazy mods, and I was able to find a 'K-case' so I had that added insurance. Here is what she looked like when complete (The builder sent me this pic cause he knew I was excited about it. Cool guy):

List of additions to this tranny:

- HD Direct Drum

- 36 Element Intermediate Sprag

- TCI Reverse Manual Valve Body with Engine braking (P/N 321115)

- Coan Racing "Super Pan" kit

- Stef's Fabrication deep pan

- Rear Mounted filter adapter

- New Pump (ouch, wasn't planning on having to replace it)

- Standard rebuild kit

- Lokar "Anchor Tight" dipstick

- Note: Had one of these on the CJ, and it worked great except when upside down the tranny fluid still made it out the tube. Will be looking for suggestions on how people address this later.

"Stef’s Fabricated Aluminum Deep Pan -“Super Filter” w/ Rear Pick-up for Improved Oil Control "

This is meant for drag racing, but a rear mounted pickup sounded like a step in the right direction. I called them and they pointed me toward how to get the pan and pickup. Done and done.

Some stuff I should have done before taking it to the builder that I still have to address:

- Tap the vent on the top of the housing for threaded vent setup

- not going to pay the builder to disassemble after the fact

- I called him and he thought that if I use a tap with a lot of grease and be careful I can do it

- He also said when this first spins up, it will build positive pressure inside the housing and blow air outward.

- Decide where I want to run the trans temp sensor, if I wanted it threaded in to the tranny this would have been the time to address it

- Would have been "cleaner" to have the sensor threaded into the transmission, which I still can do.

- I want this sensor to be in the hottest location possible for the fluid lifecycle. I have heard that outbound fluid in the line will read hotter than a sensor threaded into the housing, so this might not be a problem.

- Why the hottest?

- I want to know exactly how hot the trans fluid is getting for maintenance/ fluid lifecycle purposes

- With the digital dash I am building I have a lot of flexibility. I plan on running another sensor immediately after the cooler to determine how efficient my setup is working.

- Why the hottest?

Upcoming plans for transmission:

- Shifter

- Used to running the Art-Carr/winters shifter

- Considering the SHO speed shifter, as its simple and clean

- Digital dash

- Gear selection read out

- Universal gear shift sending unit

- I spoke with these guys and it sounds like the decoder just sends a signal to a specific wire based on what gear you have selected

- Micro controller wired to raspberry pi for dash

- I will wire in a controller and create the code to determine which wire is providing the signal (power or ground cant remember right now), then pass that message to the dash

- Flip clock for gear designation

- Here is a flipclock if youre not familiar

- Im thinking I will create a flipclock animation that will sit dead center bottom on the dash to show which gear the transmission is in. I already have a couple options coded up for it, just need to decide what looks good.

- Universal gear shift sending unit

- Gear selection read out

- Transmission thermostat

- Currently considering Improved Racing's Flow Series Motor Sport Oil Thermostat

- Cooler

- Currently considering the CBR Dual pass with 12" fan

- Note: Since I created my parts spreadsheet (easily two years) the price has increased from $739 to $850, and is now $819

- Currently considering the CBR Dual pass with 12" fan

Last edited:

YeeP

Red Skull Member

note: It's easy for me to nitpick choices I made then, because of what I know now. I'll try to not do that so you see some of the struggles I went through.

So as the process continues here, it was time that I could mount the drivetrain in the chassis. I wanted the ability to make height adjustments for the drivetrain, and a way to easily move it around on the table. This isn't a tool I care to have after the project.

Wood then!

As long as I had some kinda "sled" to move the drivetrain around and it could handle the weight, all is good. I picked the absolute lowest height I felt comfortable with. I believe the trans pan was approximately 3/8" off the top of where the skid plate would be. Going for the best possible CG height here.

As you may notice above, the original skid crossmembers where in the way, so I cut them off and kept them for later. You can also see here that the starter/adapter actually is lower than the transmission. At this mounting position, It would be slightly lower than the belly pan, so some specially configured skid for it would be needed.

This pic doesnt really show the issue but you can see the trans to tcase adapter there. With the drivetrain so low in the chassis, that adapter was also very close to the top of the skidplate. Close enough that I couldn't fit any kind of steel in there to make a crossmember, and I am not mounting my drivetrain to my skid plate. That is a mf'er to work on, and it allows the drivetrain to take impacts from the skid. Another option I have seen people do is run a tube over the tcase, and hang it from there. At the time, I was interested in saving the seat mounts that you can see going across the chassis. I also just really have an issue with hard mounting the drivetrain. I have plenty of friends that do it, it just is something I'm not comfortable with. Also this chassis seems pretty rigid to me, but I have no idea what kind of twisting or flexing it could transfer. Better to be safe and use bushings IMO.

So in looking at the TMR ARCHETYPE Universal mount, I had an idea. I could squeeze a piece of 1.75" above and slightly in front of the "foot" of the adapter.

Thats two ply of cardboard plus a lot of tape on the tranny pan. It fit.

The upward facing bolt head was about 1/8" from the top of skid. Not ideal, but I was planning on plenty of bracing and using AR400, AR450, or AR500 for the skid (we can debate that together later, looking forward to getting your opinions).

Slight miss-calculation on tube width required me to slug it and make a new section.

And that was that for the transmission mount. Next post will be engine and what followed.

Anyone reading this thinking about building something but hasn't before: tack everything. As soon as you think you have a problem solved, another will arise.

So as the process continues here, it was time that I could mount the drivetrain in the chassis. I wanted the ability to make height adjustments for the drivetrain, and a way to easily move it around on the table. This isn't a tool I care to have after the project.

Wood then!

As long as I had some kinda "sled" to move the drivetrain around and it could handle the weight, all is good. I picked the absolute lowest height I felt comfortable with. I believe the trans pan was approximately 3/8" off the top of where the skid plate would be. Going for the best possible CG height here.

As you may notice above, the original skid crossmembers where in the way, so I cut them off and kept them for later. You can also see here that the starter/adapter actually is lower than the transmission. At this mounting position, It would be slightly lower than the belly pan, so some specially configured skid for it would be needed.

This pic doesnt really show the issue but you can see the trans to tcase adapter there. With the drivetrain so low in the chassis, that adapter was also very close to the top of the skidplate. Close enough that I couldn't fit any kind of steel in there to make a crossmember, and I am not mounting my drivetrain to my skid plate. That is a mf'er to work on, and it allows the drivetrain to take impacts from the skid. Another option I have seen people do is run a tube over the tcase, and hang it from there. At the time, I was interested in saving the seat mounts that you can see going across the chassis. I also just really have an issue with hard mounting the drivetrain. I have plenty of friends that do it, it just is something I'm not comfortable with. Also this chassis seems pretty rigid to me, but I have no idea what kind of twisting or flexing it could transfer. Better to be safe and use bushings IMO.

So in looking at the TMR ARCHETYPE Universal mount, I had an idea. I could squeeze a piece of 1.75" above and slightly in front of the "foot" of the adapter.

Thats two ply of cardboard plus a lot of tape on the tranny pan. It fit.

The upward facing bolt head was about 1/8" from the top of skid. Not ideal, but I was planning on plenty of bracing and using AR400, AR450, or AR500 for the skid (we can debate that together later, looking forward to getting your opinions).

Slight miss-calculation on tube width required me to slug it and make a new section.

And that was that for the transmission mount. Next post will be engine and what followed.

Anyone reading this thinking about building something but hasn't before: tack everything. As soon as you think you have a problem solved, another will arise.

Last edited:

Scooter

walk home clown

Thanks for sharing your build. Have fun!

YeeP

Red Skull Member

Time to move into the engine mounts. I found a "crossmember kit" on ruff stuff that had the tubes, bushings, and tabs that were fairly large in height that would work. I had to make new motor plates, as the ones that I got from Marked where for a different position on the engine that was in the way of exhaust. With the relatively narrow area allowed by the new motor plate, I had to reduce the bushings to fit a 1.5" wide tube. I cut a piece of scrap to the known overall width and used it as a method to make sure the tabs would be the correct width.

Guess I missed the part on Ruff Stuff where it said these tabs were 3/8"! oh well.. The plates from the original Marked Motorsports kit were 1/8" which Jake was sure was all I needed. When I asked him if he made them in 1/4" he said no and asked me why I needed something that thick. Well Jake, its cause I was welding it to a 3/8" tab.

Tacking the motor mount together via some TIG. I'll call it not great, but not terrible. Still learning about pace mixed with heat and the balance.

I found a great place to build the mounts on the chassis, and fishmounthed the proper length tubes to make it happen.

Basically I was a certified bad ass here. Very proud to get the drivetrain in without much modification to the chassis. Again saving myself that precious time.

Another pic of everything holding its' own weight.

I spent a lot of time looking at suspension design. Even dusted this baby off (Suspension God anyone?)...

I found the new 4 Link Calculator, and a new buddy Treefrog.

I knew I probably wouldn't use the mounts that were on the chassis. What I didn't do was determine where the suspension will need to be to perform they way I am hoping it will. After lots of talking to other builders, and working with TreeFrog, it was determined that I needed to triangulate my lowers.

The drivetrain was too low for that... Time for some humble pie.

Time for some humble pie.

The crossmember and motor mounts were not going to work. So I put the drivetrain back on the wood mount and "adjusted" it to ride higher in the chassis.

More to come.

Guess I missed the part on Ruff Stuff where it said these tabs were 3/8"! oh well.. The plates from the original Marked Motorsports kit were 1/8" which Jake was sure was all I needed. When I asked him if he made them in 1/4" he said no and asked me why I needed something that thick. Well Jake, its cause I was welding it to a 3/8" tab.

Tacking the motor mount together via some TIG. I'll call it not great, but not terrible. Still learning about pace mixed with heat and the balance.

I found a great place to build the mounts on the chassis, and fishmounthed the proper length tubes to make it happen.

Basically I was a certified bad ass here. Very proud to get the drivetrain in without much modification to the chassis. Again saving myself that precious time.

Another pic of everything holding its' own weight.

I spent a lot of time looking at suspension design. Even dusted this baby off (Suspension God anyone?)...

I found the new 4 Link Calculator, and a new buddy Treefrog.

I knew I probably wouldn't use the mounts that were on the chassis. What I didn't do was determine where the suspension will need to be to perform they way I am hoping it will. After lots of talking to other builders, and working with TreeFrog, it was determined that I needed to triangulate my lowers.

The drivetrain was too low for that...

Time for some humble pie.

Time for some humble pie.The crossmember and motor mounts were not going to work. So I put the drivetrain back on the wood mount and "adjusted" it to ride higher in the chassis.

More to come.

Attachments

Last edited:

chaplinfj60

Well-known member

the calc is awesome, i know this is against the grain, but just mock some shit up where it will work and run them numbers. i dont have much experience but what i do know is its all a trade off somewhere. if you get it perfect here, it messes this up, then you get that good and it fucks up something else totally unrelated. this is by far the most nerve racking part, questioning everythin

i dont know, hell just rambling . love the progress by the way...

i dont know, hell just rambling . love the progress by the way...

YeeP

Red Skull Member

So with the new raised drivetrain height, the engine coolant output/input ports hit the lower dashboard crossmember.

As surgical as possible I removed the minimum amount of steel, even saved the seat mount tubes so I could continue to test fit drivetrain.

Side pic of the same thing. Obviously, more changes are required, but this was about getting the engine into position, not finishing up tubes in the chassis.

This time I knew better. If suspension was going to be king in the decision tree, lets not make the mounts yet. So, I carefully positioned the axles on some new "stands" to within about 1/8" of where they would ride at ride height. All that matters here is height, not diff centering.

Man, this low rider stuff is hard.

At this point, it should be apparent that 2.75" of vertical distance between the top of the axle tube and the chassis is not going to do. I don't think the builder of this chassis was thinking it would ride this low.

So now I got decision time. Do I want to raise the whole vehicle another 4.25" plus the bumpstop?

Here is how convincing myself went...

Guess I'll build the front of the chassis around the suspension....

Because the upper and lower frame rails were parallel, I cut it in a way I could try to use the bottom on the top, or try to salvage part of it in the future.

Man I love saving time.

As surgical as possible I removed the minimum amount of steel, even saved the seat mount tubes so I could continue to test fit drivetrain.

Side pic of the same thing. Obviously, more changes are required, but this was about getting the engine into position, not finishing up tubes in the chassis.

This time I knew better. If suspension was going to be king in the decision tree, lets not make the mounts yet. So, I carefully positioned the axles on some new "stands" to within about 1/8" of where they would ride at ride height. All that matters here is height, not diff centering.

Man, this low rider stuff is hard.

At this point, it should be apparent that 2.75" of vertical distance between the top of the axle tube and the chassis is not going to do. I don't think the builder of this chassis was thinking it would ride this low.

So now I got decision time. Do I want to raise the whole vehicle another 4.25" plus the bumpstop?

Here is how convincing myself went...

- Go two pics up, and look at how the front of the chassis is not symmetric with the back as far as how much space is between the axles and the chassis. I never liked that part about it.

- Honestly I don't need all these damn tubes up front compared to other commonly used chassis I have a ton

- Could save some weight

- I would rather have a buggy with a Jeep front grille (see post #1)

- Low CG.... important

- Gotta have some up travel, I ain't beating myself up all day hitting bumpstops

- Suspension choices should come first I suppose

- Never been a big fan of the kicked back exposed radiator up front look...

- The front of the chassis was one of the things I didn't like in the first place

Guess I'll build the front of the chassis around the suspension....

Because the upper and lower frame rails were parallel, I cut it in a way I could try to use the bottom on the top, or try to salvage part of it in the future.

Man I love saving time.

Last edited:

YeeP

Red Skull Member

100% agree, always a trade off. I think you'll see soon enough, that I am still figuring it out. The pic above is Nov 8th, 2021. This is actually one of the motivating factors for me to start this thread. I would like to get some opinions for the current decision I need to make. I don't want to jump ahead. I'll 'splain it soon.the calc is awesome, i know this is against the grain, but just mock some shit up where it will work and run them numbers. i dont have much experience but what i do know is its all a trade off somewhere. if you get it perfect here, it messes this up, then you get that good and it fucks up something else totally unrelated. this is by far the most nerve racking part, questioning everythin

i dont know, hell just rambling . love the progress by the way...

Sterlingfire

ignant

So will the engine be in the way of your diff / drive shaft now?

YeeP

Red Skull Member

It is out of the way at this point today. Honestly the axle is still at the same position on the "chassis" as well. The "new" engine position detailed above is actually higher in the chassis, and farther reward than when I initially made the motor and tranny mounts. Giving the axle a little more room to breathe.So will the engine be in the way of your diff / drive shaft now?

chaplinfj60

Well-known member

Kin

Oh snap. My bad. Hahahhah100% agree, always a trade off. I think you'll see soon enough, that I am still figuring it out. The pic above is Nov 8th, 2021. This is actually one of the motivating factors for me to start this thread. I would like to get some opinions for the current decision I need to make. I don't want to jump ahead. I'll 'splain it soon.

YeeP

Red Skull Member

Sorry, don't get the reference. Promise I haven't been sitting on my thumb the whole time.Kin

Oh snap. My bad. Hahahhah

chaplinfj60

Well-known member

That is a total f up on my typing slash sending skills. Phone has shit signal so i think i sent that prematurely. Lol.

YeeP

Red Skull Member

Winch -

So being a guy that started Jeep building in the 90s, I always had a soft spot for the Warn XD9000i models. I had a dumpy old superwinch at the time and always wanted one of the cool Warns. My buddy was getting rid of an XD8000i off of his winch because it wasn't working, figured I should grab it and rebuild.

His issue was really just a melted wire and crappy remote to make it run. The side of it was broken off at the mount. I wanted to replace these with a newer style contactor. Did some research and grabbed on off Amazon.

I found that Duplicolor High Performance Wheel Coating - Graphite was a pretty close match and kinda made to go on aluminum?? I guess....

Sanded and wire wheeled down all exterior parts and went to work

I thought about rebuilding the motor myself, but found a local guy that builds motors and alternators. Took it to him and he replaced the brushes, cleaned it up and tested it for me

I bought new a new brake, new lever, all the stickers, new side piece because the one from the winch was broken, random gaskets, the contactor and a synthetic rope. All of these parts currently await assembly....

So being a guy that started Jeep building in the 90s, I always had a soft spot for the Warn XD9000i models. I had a dumpy old superwinch at the time and always wanted one of the cool Warns. My buddy was getting rid of an XD8000i off of his winch because it wasn't working, figured I should grab it and rebuild.

His issue was really just a melted wire and crappy remote to make it run. The side of it was broken off at the mount. I wanted to replace these with a newer style contactor. Did some research and grabbed on off Amazon.

I found that Duplicolor High Performance Wheel Coating - Graphite was a pretty close match and kinda made to go on aluminum?? I guess....

Sanded and wire wheeled down all exterior parts and went to work

I thought about rebuilding the motor myself, but found a local guy that builds motors and alternators. Took it to him and he replaced the brushes, cleaned it up and tested it for me

I bought new a new brake, new lever, all the stickers, new side piece because the one from the winch was broken, random gaskets, the contactor and a synthetic rope. All of these parts currently await assembly....

YeeP

Red Skull Member

Parts started to arrive

The CJ was rockin RE Joints in the back, but I decided to go with 1&1/4" Rod ends with miss-alignment washers to get down to a 3/4" bolt. I was excited to be rocking new big boy shit.

Took this pic in the fastenal parking lot.... lol

Goat Built Ram Mount

At this point I was unsure if I could save time by getting a more "generic" steering ram mount. After some research, the one from Goat Built looked like a good option.

I spoke with a guy at Goat Built who I think has the "Wolf in Jeep's Clothing" thread here. I did not want to mount the ram off center. I just don't want to deal with different angles between the tie-rods and also I don't like how it looks. He confirmed that the mount could be centered on a fabbed 9 inch housing with a little work. My first thought was to determine what it would take to center the mount.

After several mock ups and measurements on the Trail Gear housing, this is what needed to be removed from the bracket to get it centered on th

Then, I realized I fucked up. My 3X9 steering ram does not fit this mount...

For Sale one lightly tacked together non-modified Goat Built Ram mount

(seriously, still for sale)

JHF Weld on High Steer

Note: I know Jessie Haines is a big deal in most rock crawling communities. He is a solid dude that seems to generally care about helping people. I have no personal issue with the guy. Assumptions were made by me based on the overwhelming high regard everyone has for anything made by JHF. I cannot blame them for me not doing my due diligence.

After getting the 9 inch housings, I knew I only needed the Inner-C out, so this happened...

Based on a recommendations from everyone and their mother, I bought the JHF high steer kit for 05+ full hydro. At this time, my Inner-Cs were getting machined to slide over the 3.5" tubes on the axles. My axles were 2008 and 2010. So this kit fit the bill on the description.

Just by sheer luck I started the fitment with the 2010 knuckle. Grinding the inside of the plates to match the contour of the knuckle for the best fitment possible. Based on a some recommendations from a teacher at another welding class I took, I should smooth out the area on the casting I am going to weld to. So I did that too. All in all a decent fit:

Until you get to the other side. Zero material has been removed on this side from the kit.

The difference between the 2008 and 2010 knuckles is very apparent here

I knew I had modified the kit by making it fit smoothly with the knuckle, so there was no return option. I spoke with Jesse who was very cordial and said that he had seen a difference in some of the newer knuckles.

So moral of the story; do your research. I had seen year discrepancies in the kits made by several other manufacturers, but made an assumption that because this kit said JHF on it, all would be handled (I mean the thing is labeled 05+). I know Jesse makes some great stuff, but I was not going to "build a bridge" the size of my finger on a component this critical when I was already weary about welding here in the first place.

For those that wonder, the kit would have taken about 20 minutes max to have an awesome fit on the 2008 knuckles and everything would have been just fine there. I just was not going to run two different high steer setups. I went super heavy into the weeds at that time on the years the castings changed, can't remember at this point when the years they changed are.

Luckily, I put the kit up for sale for I think 20 bucks less than I paid and it sold in a day.

The CJ was rockin RE Joints in the back, but I decided to go with 1&1/4" Rod ends with miss-alignment washers to get down to a 3/4" bolt. I was excited to be rocking new big boy shit.

Took this pic in the fastenal parking lot.... lol

Goat Built Ram Mount

At this point I was unsure if I could save time by getting a more "generic" steering ram mount. After some research, the one from Goat Built looked like a good option.

I spoke with a guy at Goat Built who I think has the "Wolf in Jeep's Clothing" thread here. I did not want to mount the ram off center. I just don't want to deal with different angles between the tie-rods and also I don't like how it looks. He confirmed that the mount could be centered on a fabbed 9 inch housing with a little work. My first thought was to determine what it would take to center the mount.

After several mock ups and measurements on the Trail Gear housing, this is what needed to be removed from the bracket to get it centered on th

Then, I realized I fucked up. My 3X9 steering ram does not fit this mount...

For Sale one lightly tacked together non-modified Goat Built Ram mount

(seriously, still for sale)

JHF Weld on High Steer

Note: I know Jessie Haines is a big deal in most rock crawling communities. He is a solid dude that seems to generally care about helping people. I have no personal issue with the guy. Assumptions were made by me based on the overwhelming high regard everyone has for anything made by JHF. I cannot blame them for me not doing my due diligence.

After getting the 9 inch housings, I knew I only needed the Inner-C out, so this happened...

Based on a recommendations from everyone and their mother, I bought the JHF high steer kit for 05+ full hydro. At this time, my Inner-Cs were getting machined to slide over the 3.5" tubes on the axles. My axles were 2008 and 2010. So this kit fit the bill on the description.

Just by sheer luck I started the fitment with the 2010 knuckle. Grinding the inside of the plates to match the contour of the knuckle for the best fitment possible. Based on a some recommendations from a teacher at another welding class I took, I should smooth out the area on the casting I am going to weld to. So I did that too. All in all a decent fit:

Until you get to the other side. Zero material has been removed on this side from the kit.

The difference between the 2008 and 2010 knuckles is very apparent here

I knew I had modified the kit by making it fit smoothly with the knuckle, so there was no return option. I spoke with Jesse who was very cordial and said that he had seen a difference in some of the newer knuckles.

So moral of the story; do your research. I had seen year discrepancies in the kits made by several other manufacturers, but made an assumption that because this kit said JHF on it, all would be handled (I mean the thing is labeled 05+). I know Jesse makes some great stuff, but I was not going to "build a bridge" the size of my finger on a component this critical when I was already weary about welding here in the first place.

For those that wonder, the kit would have taken about 20 minutes max to have an awesome fit on the 2008 knuckles and everything would have been just fine there. I just was not going to run two different high steer setups. I went super heavy into the weeds at that time on the years the castings changed, can't remember at this point when the years they changed are.

Luckily, I put the kit up for sale for I think 20 bucks less than I paid and it sold in a day.

Bebop

Well-known member

- Joined

- May 26, 2020

- Member Number

- 1458

- Messages

- 4,850

So in looking at the TMR ARCHETYPE Universal mount, I had an idea. I could squeeze a piece of 1.75" above and slightly in front of the "foot" of the adapter.

Thats two ply of cardboard plus a lot of tape on the tranny pan. It fit.

The upward facing bolt head was about 1/8" from the top of skid. Not ideal, but I was planning on plenty of bracing and using AR400, AR450, or AR500 for the skid (we can debate that together later, looking forward to getting your opinions).

This crossmember / mount looks to me that it'll makin removing the atlas and/or the trans pan a giant pain ?

YeeP

Red Skull Member

Good question. If you look at the last pic in that section I welded it together with those TMR Interlocking ID tube clamps.This crossmember / mount looks to me that it'll makin removing the atlas and/or the trans pan a giant pain ?

This is how disassembly went:

- Unbolt TMR tube clams

- Unbolt long bolt going through bushing

- Unbolt plate bolted to t-case adapter and set it aside

- Rotate the crossmember forward approximately 30 degrees (it would pivot out of those tube clamps when doing this)

- Pull crossmember straight down

The tranny pan drops straight down on that TH350, so that wouldn't be tough.

The atlas is 100% behind the crossmember (minus the front output of course), so it wasn't really in the way.

Last edited:

YeeP

Red Skull Member

No, it could stay in there and remove/install the atlas. As far as trans filter, I was able to drop the pan in testing, so I think it would not be too bad. Another thing which I didn't mention yet, is I am running a remote trans filter in addition to the main on in the pan. That will be my typical maintenance related filter change while the pan filter replacement will be at longer intervals.I meant, do you need to remove the crossmember everytime you need to change the trans filter and / or if you need to remove the atlas.

Something I might not have made clear: When I get to the part where I talk about eating humble pie, the trans mount is gone, in the scrap pile. As well as the motor mounts I made. I had to reposition the whole drivetrain upward and more rearward. (hence it is back on the wood). The trans currently sits in a place where I might even be able to fit a standard low profile GM bushing on the adapter and run a typical crossmember next to it.

EDIT: I edited that post to make it clear that is what I meant. Sorry if it was confusing.

Last edited:

YeeP

Red Skull Member

My timeline is not right! In scanning through my pictures I don't have like a generic unboxing pic of my front diff. So I saw this one close to when I removed the front of the chassis.

Mega Hi-9

The decision to get an 9" housing for the front in particular was made in conjunction with knowing I wanted a high pinion. I have a friend that is running this diff in his buggy without issue. I have since seen some negative talk about it on FB with people saying to buy the Gearworks diff instead. Im sure the Gearworks diff is bad to the bone, but it's just not in my budget. Especially because I want to hopefully run a high pinion rear, so I need two.

I spent a lot of time on the phone with the Mega Hi-9 guy (he will talk your ear off ), and felt fairly confident that this would work for me. Another benefit of the J35, I just really don't have as much power as I would with an LS. So I ordered one and here is a pic of it sitting in the housing.

), and felt fairly confident that this would work for me. Another benefit of the J35, I just really don't have as much power as I would with an LS. So I ordered one and here is a pic of it sitting in the housing.

I realized I must have skipped talking about it, because without the pinion location I wouldn't be able to know where the center of the front axle would be (used the pinion to determine axle side to side positioning in the chassis)

The diff as it sits is 5.40 R&P, with a 40 spline spool. 1410 billet yoke.

Mega Hi-9

The decision to get an 9" housing for the front in particular was made in conjunction with knowing I wanted a high pinion. I have a friend that is running this diff in his buggy without issue. I have since seen some negative talk about it on FB with people saying to buy the Gearworks diff instead. Im sure the Gearworks diff is bad to the bone, but it's just not in my budget. Especially because I want to hopefully run a high pinion rear, so I need two.

I spent a lot of time on the phone with the Mega Hi-9 guy (he will talk your ear off

), and felt fairly confident that this would work for me. Another benefit of the J35, I just really don't have as much power as I would with an LS. So I ordered one and here is a pic of it sitting in the housing.

), and felt fairly confident that this would work for me. Another benefit of the J35, I just really don't have as much power as I would with an LS. So I ordered one and here is a pic of it sitting in the housing.I realized I must have skipped talking about it, because without the pinion location I wouldn't be able to know where the center of the front axle would be (used the pinion to determine axle side to side positioning in the chassis)

The diff as it sits is 5.40 R&P, with a 40 spline spool. 1410 billet yoke.

Last edited:

Bebop

Well-known member

- Joined

- May 26, 2020

- Member Number

- 1458

- Messages

- 4,850

Understood.No, it could stay in there and remove/install the atlas. As far as trans filter, I was able to drop the pan in testing, so I think it would not be too bad.

[...], the trans mount is gone, in the scrap pile. As well as the motor mounts I made. [...]

Pics made it look way worse than it was then.

No worries on the redoing stuff, I had to redo every single bracket on my buggy at least once.

Sterlingfire

ignant

I hope you went with weaver arms instead of weld on for the second iteration

YeeP

Red Skull Member

I hope you went with weaver arms instead of weld on for the second iteration

Time will tell.

Time will tell.YeeP

Red Skull Member

So, at this point I needed to make the dashboard crossmembers right as I knew this was going to be a new position for the drivetrain. Thankfully the chassis builder left me some clues as to where the brake booster and steering shaft would peak through. I assumed that seats had possibly been in it at one point and that is when this was done. I took measurements of everything I could, and tucked them away.

Here is the careful extraction of what I don't need...

Where I last had it:

I'll be the first one to point out that some of these tubes may have gotten a little hot based on the heat affected zone. At this point, it is what it is. I did my best to only cut what was going to be removed in an effort to only replace the lower dash tube.

A lot of grinding in the future for me. I really liked the little under dash storage area that was here, but it was in the way. I may try and make something like this later.

careful grinding to remove what was left of the tube this was fishmouthed to

You can see here that I also carefully removed all remnants of the previous engine roll cage.

This was the only pic I could find of the ingoing tubes to replace the lower dash. I bought a pipe polishing belt sander right before this and was bored in the garage so I decided to see what they would look like if I went from 80 grit stepping all the way to 400 grit. Kinda cool.

I also could not find a pic of the finished product, so I went way ahead in the timeline and carefully extracted a pic of them welded in. Its not great, but you'll get the picture.

Here is the careful extraction of what I don't need...

Where I last had it:

I'll be the first one to point out that some of these tubes may have gotten a little hot based on the heat affected zone. At this point, it is what it is. I did my best to only cut what was going to be removed in an effort to only replace the lower dash tube.

A lot of grinding in the future for me. I really liked the little under dash storage area that was here, but it was in the way. I may try and make something like this later.

careful grinding to remove what was left of the tube this was fishmouthed to

You can see here that I also carefully removed all remnants of the previous engine roll cage.

This was the only pic I could find of the ingoing tubes to replace the lower dash. I bought a pipe polishing belt sander right before this and was bored in the garage so I decided to see what they would look like if I went from 80 grit stepping all the way to 400 grit. Kinda cool.

I also could not find a pic of the finished product, so I went way ahead in the timeline and carefully extracted a pic of them welded in. Its not great, but you'll get the picture.

Cool build and thanks for sharing. Sub'd after this comment.

I was not expecting to see a Honda v6 going into "rock bouncer" style chassis, way to be different, I like it. Being an old school honda boy back in the day I almost went down the j-series path until I saw how much everything else adds to cost to run this super cheap motor.

lookin forward to updates.

EDIT: removed misleading / false information about Hondata ECU for the j35.

I was not expecting to see a Honda v6 going into "rock bouncer" style chassis, way to be different, I like it. Being an old school honda boy back in the day I almost went down the j-series path until I saw how much everything else adds to cost to run this super cheap motor.

lookin forward to updates.

EDIT: removed misleading / false information about Hondata ECU for the j35.

Last edited:

YeeP

Red Skull Member

Hey man I'm out to dinner with the home boss. I will post something more specific but I'd like to hear about what you know about the ecm related troubles. Going to be looking up hondata.Cool build and thanks for sharing. Sub'd after this comment.

I was not expecting to see a Honda v6 going into "rock bouncer" style chassis, way to be different, I like it. Being an old school honda boy back in the day I almost went down the j-series path until I saw how much everything else adds to cost to run this super cheap motor.

Since you're neck deep now I'd highly consider running a Hondata with this motor. It'll make eliminating wiring and components much easier, Honda ecm's are a pain to deal with/unlock/crack unless running a stock motor and all components. While you can run this motor with stock ECU and harness, Why mess with an ECU you can't touch, if you went LS I'm assuming that you'd run a holley system with digital dash, the Hondata is as close as one gets to a standalone.

lookin forward to updates.

I'll explain my plans for my dash build when I get home.

Thanks for the reply!

YeeP

Red Skull Member

Hey man, sorry I uhh.... had too many whiskeys last night.Cool build and thanks for sharing. Sub'd after this comment.

I was not expecting to see a Honda v6 going into "rock bouncer" style chassis, way to be different, I like it. Being an old school honda boy back in the day I almost went down the j-series path until I saw how much everything else adds to cost to run this super cheap motor.

Since you're neck deep now I'd highly consider running a Hondata with this motor. It'll make eliminating wiring and components much easier, Honda ecm's are a pain to deal with/unlock/crack unless running a stock motor and all components. While you can run this motor with stock ECU and harness, Why mess with an ECU you can't touch, if you went LS I'm assuming that you'd run a holley system with digital dash, the Hondata is as close as one gets to a standalone.

lookin forward to updates.

First of all, thank you for the comment about the bouncer style with this engine. I also was excited to bring the two together. I like how bouncers look, but I want this to perform as a trail crawler. You are damn right about the all the added cost to actually use the engine. I do have a spread sheet and at least at the point I'm at right now, it ended up being about 1K more than doing an LS. At least at the prices I was getting when I was making decisions.

As far as the ECU goes, I feel like its better to give you a little context so you know why I'm here. My CJ EFI system was a mix of many parts from systems that weren't exactly together from the factory. I had a setup to flash chips from my computer at home, and worked on my fuel mapping and ignition mapping quite often (mid to late 90s TBI tech we are talking here). I am not a tuner, and it ate a lot of my time. When I got the J35, before Jake put that huge rant on the wiring harness part of the Marked Motorsports website, he had a nice writeup about the advantages to running the stock ECU. Dependability, less time spending tuning. I knew I wasn't interested in building the hell out of an engine to only go an abuse it off road, so that kind of spoke to me. So in an effort to save myself the headache of being frustrated with how my engine was running, because of something I may or may not have done correctly, I decided to stay stock.

EDIT: Hey I was wrong, Jakes writeup is still on their site. Here is his take on the J35: Why A Honda V6? Size, Weight, Tunablity, Honda Reliability! - It's Free! : Marked Motorsports, Team Website

I am interested in what Hondata will do for making wiring easier.

As far as cracking the ECU, I don't think I will need to. I need to give Jake a ring to just confirm a couple things, but I believe I was told that it has been flashed to remove the vehicle theft stuff, and possibly deal with the lack of EGR? Although based on your statement about how they are difficult to crack, I worry.

My modifications to the harness to create the digital dash are more meant to be for tapping into the communication to and from the ECU. More of a man in the middle if you will. Something that makes this difficult, is the technology used for inter system communication on this engine, while still OBD2, are out dated. It uses whats called a K-line, which is pre single wire CAN (still old). A huge advantage for me in stepping up to an aftermarket ECU is that is will use a high/low CAN bus. There are some awesome "tools" out there to tap into this newer style of CAN bus that have already solved all the problems. If I decided to go this route, it would save me a ton of time in figuring out how to make the dash work, but I would have to then worry about tuning again.

But for now, I will have to design the communication protocols. However, I did find a microcontroller that is designed to receive a K-line signal (ISO 9141-2 protocol). ISO 9141 Click. This microcontroller really just provides a way for you to define how communication is received from the ECU. You still have to figure out what every signal that comes from it is, and how to decode it. Since the K-line is a single line communication, it really works on a communication loop. You have to send a request for data, then wait for the processing to come all the way around (it only goes in one direction like a conveyor belt). It sounds slow, and when compared to a dual line CAN, it is. But we're talking about milliseconds here.

I have been cataloging projects where people have working with the ISO-9141 protocol, bookmarking their code samples. None of them are exactly what I am doing, but they will help. Another tough part is that microcontroller should really be coded in C. Not super excited about that. Anyway, that is a little window into where I am headed.

Thanks for the interest.

Last edited: