CarterKraft

Red Skull Member

This is a buddies 2016? Maverick Max I built for trail riding.

Many of you know I suck at build threads but I will bore you with my terrible pictures and poorly put together ramblings.

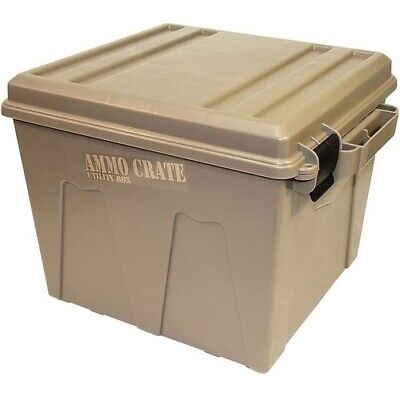

The focus is cooler space, stereo, spare tire storage, and dry locker. We quickly found out there is not much storage space in the Maverick and that would be the focus for most of the build.

A important detail was must be fully street legal (impossible in Texas but more on that later).

While trying to fit this Yet cooler full size spare etc. I realized there isn't enough room. I also found the little wings that hold the tail lights are way to fragile to be hit by limbs, trees etc. It looked a rear bumper need to be made to protect the light housings and wings and provide some structure. After the rough shape was bent up it just didn't look right and so I sort of slept on it.

Many of you know I suck at build threads but I will bore you with my terrible pictures and poorly put together ramblings.

The focus is cooler space, stereo, spare tire storage, and dry locker. We quickly found out there is not much storage space in the Maverick and that would be the focus for most of the build.

A important detail was must be fully street legal (impossible in Texas but more on that later).

While trying to fit this Yet cooler full size spare etc. I realized there isn't enough room. I also found the little wings that hold the tail lights are way to fragile to be hit by limbs, trees etc. It looked a rear bumper need to be made to protect the light housings and wings and provide some structure. After the rough shape was bent up it just didn't look right and so I sort of slept on it.

Last edited:

The frame has some UHMW pucks screwed to it so it sits hard on the lip of the wheel and the tire interference makes it hold in what ever position it is locked in.

The frame has some UHMW pucks screwed to it so it sits hard on the lip of the wheel and the tire interference makes it hold in what ever position it is locked in.