Jeff

Member

- Joined

- May 4, 2021

- Member Number

- 3879

- Messages

- 15

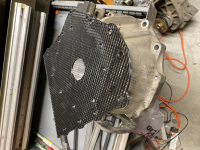

I've been building this rig for the past 2 years, at time of posting, and I figured I would share what ive done.

Drivetrain:

Dana 44 from jeep j10 Front

TJM air locker front

2000-2001 LSD rear

4.88 gears

Suspension:

Single radius arm

12 in coil overs

Mid high steer Heim steering

Drivetrain:

Dana 44 from jeep j10 Front

TJM air locker front

2000-2001 LSD rear

4.88 gears

Suspension:

Single radius arm

12 in coil overs

Mid high steer Heim steering

Attachments

-

tempImageMZnsjb.png7.7 MB · Views: 180

tempImageMZnsjb.png7.7 MB · Views: 180 -

D37F3F0A-93ED-4A07-9C73-530EDA988CF8.jpeg1.9 MB · Views: 125

D37F3F0A-93ED-4A07-9C73-530EDA988CF8.jpeg1.9 MB · Views: 125 -

208BDDB5-AEDF-40F8-B230-E45405206E3A.jpeg1.7 MB · Views: 114

208BDDB5-AEDF-40F8-B230-E45405206E3A.jpeg1.7 MB · Views: 114 -

FEDBBACA-B8E9-4D8D-898C-A0502C6393A7.jpeg1.9 MB · Views: 140

FEDBBACA-B8E9-4D8D-898C-A0502C6393A7.jpeg1.9 MB · Views: 140 -

tempImagea2yTOz.png5.9 MB · Views: 105

tempImagea2yTOz.png5.9 MB · Views: 105 -

E8C80FB0-99AB-4BA2-8CFD-084DBD25DFDB.jpeg1.6 MB · Views: 114

E8C80FB0-99AB-4BA2-8CFD-084DBD25DFDB.jpeg1.6 MB · Views: 114 -

tempImagegvKjm8.png6.2 MB · Views: 126

tempImagegvKjm8.png6.2 MB · Views: 126