Pmedic920

The ‘Stache

As I’ve said in multiple other posts, I’m in the planning/ early stages of getting my JKU back into usable form after being totaled by an 18 wheeler that ran a stop sign.

I was hit kinda broadside (driver side) and pushed sideways over a curb. Luckily this pushed both passenger side tires off the rims and I didn’t roll.

The lateral force pushed both axles a few inches towards the driver side, the rear axle more so than front. The force primarily was transferred via the track bar, and it ripped the mount off of the rear axle and mangled the bolt on track bracket.

When I contacted MetalCloak to order a new bracket they wisely recommended that I purchase a weld on bracket instead of another bolt on that would require welding on the factory mounting point anyway.

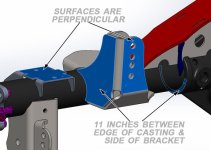

I did a bit of research and ordered the bracket from Artec.

Bla bla bla, that’s a lot of unnecessary words to ask a simple question but I figured maybe someone needed something to read, and my problems might make someone else feel a bit better about their own.

Anyway, I’ll have to haul the jeep to a welder/fab shop and my question is this.

Can the track bar bracket simply be welded up to the tube or do I need to drain all the lube and pull the axle shaft. I understand that heat transfer is an issue but uncertain how big a deal it is.

Do I need to request a particular type of weld, is there a risk of burning through the tube if I inadvertently choose an idiot to do my work?

Again, I don’t weld and other than a basic understanding I’m pretty ignorant.

I’ll take any advice that will help, short of sell the JKU and build a buggy (already admitted “I don’t weld”)

Thanks Fellas

ETA:

The Artec bracket seems to be good quality but it wasn’t a ton of money, if there is a way better option I’d certainly consider a different choice.

I was hit kinda broadside (driver side) and pushed sideways over a curb. Luckily this pushed both passenger side tires off the rims and I didn’t roll.

The lateral force pushed both axles a few inches towards the driver side, the rear axle more so than front. The force primarily was transferred via the track bar, and it ripped the mount off of the rear axle and mangled the bolt on track bracket.

When I contacted MetalCloak to order a new bracket they wisely recommended that I purchase a weld on bracket instead of another bolt on that would require welding on the factory mounting point anyway.

I did a bit of research and ordered the bracket from Artec.

Bla bla bla, that’s a lot of unnecessary words to ask a simple question but I figured maybe someone needed something to read, and my problems might make someone else feel a bit better about their own.

Anyway, I’ll have to haul the jeep to a welder/fab shop and my question is this.

Can the track bar bracket simply be welded up to the tube or do I need to drain all the lube and pull the axle shaft. I understand that heat transfer is an issue but uncertain how big a deal it is.

Do I need to request a particular type of weld, is there a risk of burning through the tube if I inadvertently choose an idiot to do my work?

Again, I don’t weld and other than a basic understanding I’m pretty ignorant.

I’ll take any advice that will help, short of sell the JKU and build a buggy (already admitted “I don’t weld”)

Thanks Fellas

ETA:

The Artec bracket seems to be good quality but it wasn’t a ton of money, if there is a way better option I’d certainly consider a different choice.