bgaidan

Red Skull Member

- Joined

- Jul 18, 2020

- Member Number

- 2322

- Messages

- 2,943

This:True, but thats not in the budget yet. I might do when I add locking hubs.

Next question, does anyone know if chev brake lines will bolt up or does Nissan use some weird metric size? I'm looking for a simple way to get longer brake lines.

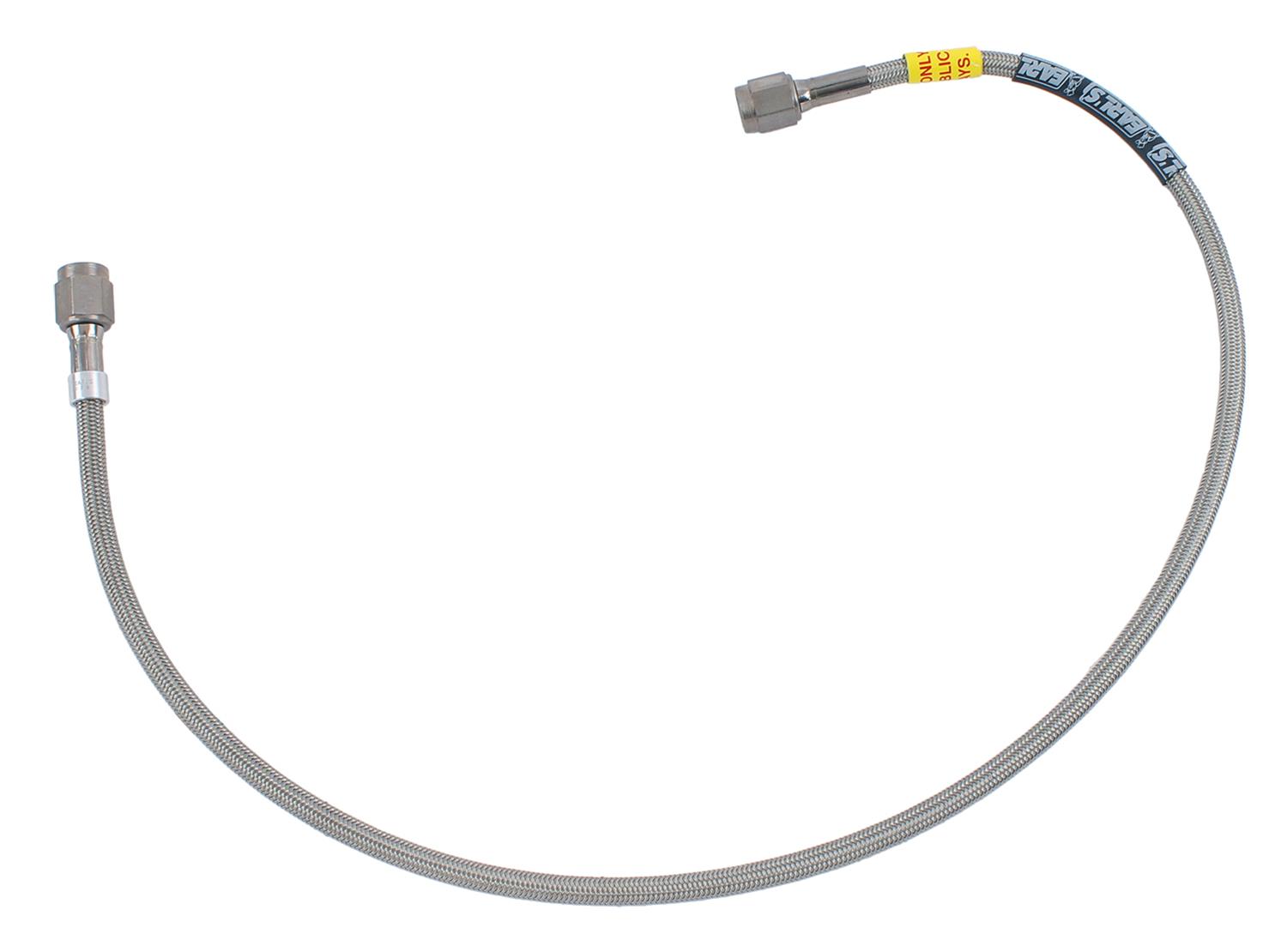

Earl's Performance 63010124ERL Earl's Performance Speed-Flex Brake Lines | Summit Racing

Free Shipping - Earl's Performance Speed-Flex Brake Lines with qualifying orders of $109. Shop Brake Hoses, Individual at Summit Racing.

Summit Racing SUM-220328 Summit Racing™ Brake Fittings | Summit Racing

And:

Earl's Performance 989537ERL Earl's Performance Brake System Adapters | Summit Racing

Free Shipping - Earl's Performance Brake System Adapters with qualifying orders of $109. Shop Brake Fittings at Summit Racing.

Will get you from the stock M10 fitting on the frame to the proper jeep/chevy D44 caliper banjo.

I only know because I ripped one of my lines off on the trail a few weeks ago and someone just happened to have those as spares. So I came home and ordered 3 sets + his replacement.

Really wish I filled it up then.

Really wish I filled it up then.